What Affects the Cost of Custom Lithium Battery Packs?

What drives the cost of custom lithium batteries? Explore expert insights, design tips, and real-world strategies to balance price and performance in your next project.

Get a quote

What Factors Influence Custom Battery Pack Manufacturing Prices?

Answer: Custom battery pack manufacturing prices depend on cell chemistry, capacity, design complexity, safety certifications, and order volume. Lithium-ion batteries cost

Get a quote

Lithium-Ion Battery Pack Prices See Largest Drop

New York, December 10, 2024 – Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a

Get a quote

Custom Batteries, Battery Packs, OEM Pack Assemblies

Sample of our UN38.3 tested batteries. Help to apply IEC62133 for battery packs build by battery space. Sample of Custom Nimh battery packs, Custom Lithium Ion 18650 battery packs,

Get a quote

Lithium-Ion Battery Costs: Manufacturing Prices, Components,

Prices depend on battery chemistry, like LFP or NMC, and geography, such as China or the West. For electric vehicle packs, costs range from $7,000 to $20,000. In mass

Get a quote

Why Are Lithium Batteries So Expensive To Make?

The cost of lithium batteries is influenced by factors including cell composition, battery management systems, custom pack design, and testing/certification. Understanding these

Get a quote

EV batteries now cost 115 USD per kWh on average

According to a recent analysis, the average price of lithium-ion battery packs for electric vehicles fell by 20 per cent to USD 115 per kilowatt

Get a quote

Pack to Cell Cost Ratio

The average price of cells to pack is considered to be around 70% with a well optimised pack achieving 80%. Using the above values we can replot this as a ratio.

Get a quote

Custom Lithium Ion Battery Pack Manufacturer From

Custom Battery Packs Portable Power Solutions from Design to Delivery for Over 10 Years Since 2008, Huizhou JB Battery Technology Limited has been

Get a quote

How Much Does a Lithium-Ion Battery Cost in 2024?

An average lithium battery costs around $139 per kWh in 2024. Learn all about the price trends, battery comparisons, and factors that decide these battery prices.

Get a quote

Why Are Lithium Batteries So Expensive To Make?

The cost of lithium batteries is influenced by factors including cell composition, battery management systems, custom pack design, and testing/certification.

Get a quote

Voltx.ai Software: design Battery Packs Online

Voltaplex Energy launched Voltx.ai Alpha, a battery design automation cloud software that will enable engineering teams to rapidly prototype new lithium

Get a quote

Lithium-ion battery

A lithium-ion battery, or Li-ion battery, is a type of rechargeable battery that uses the reversible intercalation of Li + ions into electronically conducting solids to

Get a quote

Wave of Decline Sweeps Lithium-Ion Battery Pack Pricing, in

Lithium-ion battery pack prices dropped 20% in 2024, reaching $115/kWh. EV battery prices dip below $100/kWh—explore the trends behind this decline.

Get a quote

(PDF) Mechanical Design of Battery Pack

This project offers a detailed overview of the process involved in designing a mechanical structure for an electric vehicle''s 18 kWh battery pack.

Get a quote

Lithium Block™ — 3.6 Volt Battery Module | CIE

Lithium Battery Industry Our team of engineers have designed an easy to integrate, affordable solution. Meet Lithium Block™. This durable battery pack

Get a quote

What Determines Custom Battery Pack Manufacturing Prices?

Custom battery pack manufacturing prices depend on design complexity, material choices, production volume, and certifications. Costs range from $50 to $500+ per unit, with

Get a quote

Lithium

The recent increase in price has stemmed from rising raw material prices and battery component prices, but overall battery pack prices are forecasted to decline further into

Get a quote

EV Lithium Ion Battery Pack: From Lifespan to Price Drops

Now, the cost has dropped to roughly $6,000–$7,000. With mass production and new technologies, prices are expected to continue falling, making EVs more affordable relative

Get a quote

Battery price per kwh 2025| Statista

The cost of lithium-ion batteries per kWh decreased by 20 percent between 2023 and 2024. Lithium-ion battery price was about 115 U.S. dollars per kWh in 202.

Get a quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

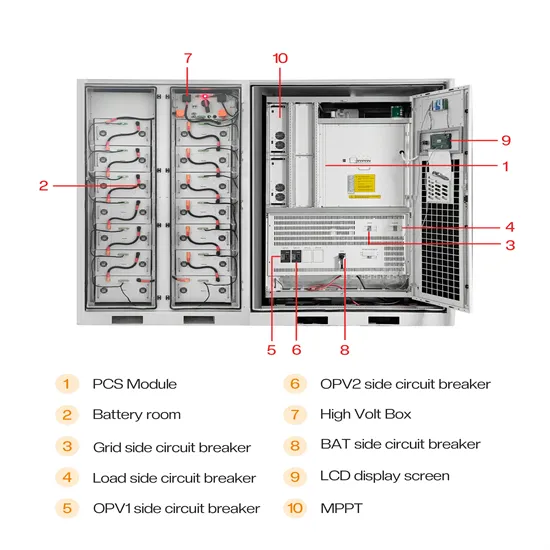

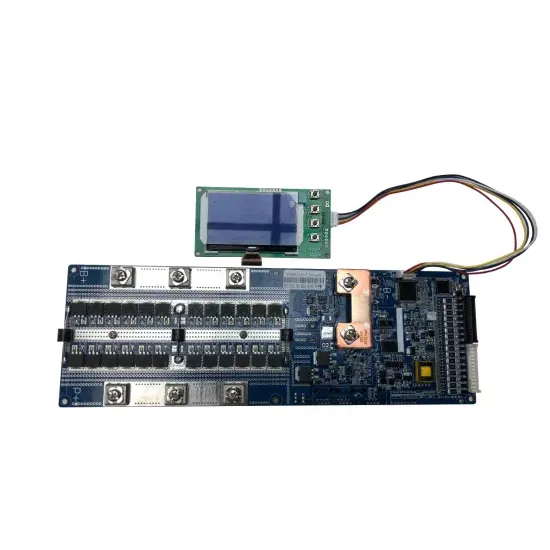

What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get a quote

Lithium-ion Battery Pack Prices Rise for First Time to

BloombergNEF''s annual battery price survey finds prices increased by 7% from 2021 to 2022 New York, December 6, 2022 – Rising raw material

Get a quote

6 FAQs about [Lithium battery pack design price]

How much does a lithium battery pack cost?

Lithium battery pack manufacturers must certify lithium battery packs for safety before transport. Some certifications, like CE, are done in-house; others require external labs. Costs range from $500 to $30,000, depending on the certification type. Sample packs are needed for both destructive and non-destructive tests.

What factors affect the cost of lithium batteries?

Key Takeaways: The cost of lithium batteries is influenced by factors including cell composition, battery management systems, custom pack design, and testing/certification. Understanding these elements is crucial for effectively managing expenses and optimizing battery performance.

What was the cost of a lithium ion battery pack in 2020?

Thanks in part to our efforts, the cost of a lithium ion battery pack dropped to less than $140/kWh in 2020. We’re looking to build on that progress in the years ahead.

What are the important considerations in lithium-ion battery pack design?

Another important consideration in lithium-ion battery pack design is ease of follow-up maintenance. In lithium-ion battery pack designs, some producers use mechanical components, bolts or nuts to link the cell. This kind of design allows the user to replace the cell and use the pack throughout the life of battery.

Is there a standard size for a lithium battery pack?

First, we need to note that there is no standard size for lithium battery pack, nor is there likely to be any in the near future, for a simple reason: different manufacturers build and integrate electric vehicles differently. The power lithium battery pack needs to adapt to the vehicle structure, so it is difficult to have a uniform size standard.

Should you add additional components to a custom battery pack system?

In the process of designing a custom battery pack system, adding extra components will proportionally increase manufacturing costs. It is also important to note that substituting certain components with lower-cost materials (such as relays) may affect overall performance and battery lifespan.

Guess what you want to know

-

Lithium battery pack price and weight

Lithium battery pack price and weight

-

Pack lithium battery factory design

Pack lithium battery factory design

-

Ukrainian solar lithium battery pack price

Ukrainian solar lithium battery pack price

-

Tajikistan professional lithium battery pack factory price

Tajikistan professional lithium battery pack factory price

-

Botswana 15ah lithium battery pack price 48 volt

Botswana 15ah lithium battery pack price 48 volt

-

Papua New Guinea lithium battery pack price

Papua New Guinea lithium battery pack price

-

15ah lithium battery pack price 48 volt in Estonia

15ah lithium battery pack price 48 volt in Estonia

-

Palestine solar lithium battery pack price

Palestine solar lithium battery pack price

-

Average price of energy storage lithium battery pack

Average price of energy storage lithium battery pack

-

Reference price of good lithium battery pack in Croatia

Reference price of good lithium battery pack in Croatia

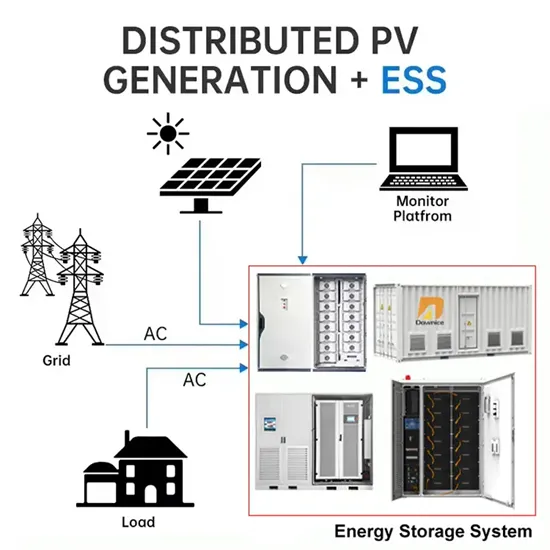

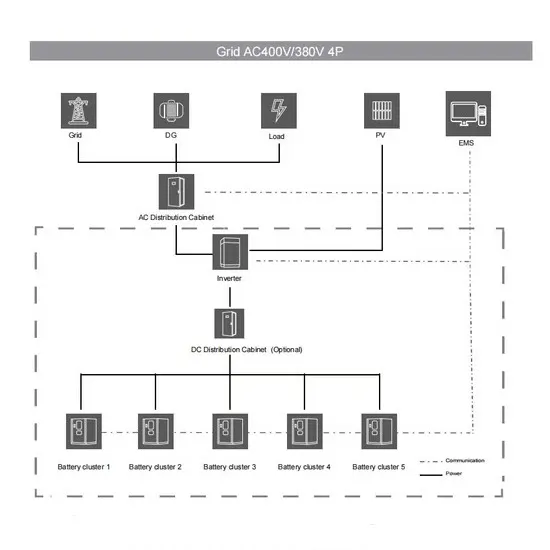

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.