Tutorial : How To Make LITHIUM BATTERY PACKS Best Money

In this video I will be explaining you, How to Make Lithium Battery Packs which is now one of the best money making methods in the game as one unit sells for...

Get a quote

Battery Factory How to Build the Lithium-Ion Battery Pack?

How to Build a Lithium-Ion Battery Pack? Lithium-ion battery pack mainly has two meanings. The first is the processing and assembly of lithium-ion battery packs. The second

Get a quote

Battery Manufacturing-How We Build Your Custom Battery Packs

Looking for 18650 or 21700 lithium ion battery packs tailored to your needs? Whether it''s compact and lightweight packs for portable devices or high-power solutions for

Get a quote

How To Establish A Battery Pack Manufacturing Factory

Building a battery pack manufacturing factory is a strategic endeavor that requires meticulous planning, technical expertise, and a clear understanding of market demands.

Get a quote

Battery Pack Manufacturing Process

In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations. Whether you''re a

Get a quote

What Is the Process of Lithium-Ion Battery Pack Assembly

The lithium battery pack plays a crucial role in the manufacture of lithium-ion batteries, involving packaging, encapsulation, and assembly. This process is divided into three

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

How To Set Up A Lithium-Ion Battery Manufacturing Plant In India

Includes free support Lithium-Ion Battery Learn how to establish a Lithium-ion battery manufacturing facility in India. Explore the process, requirements, and opportunities for setting

Get a quote

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Get a quote

What Is the Process of Lithium-Ion Battery Pack

The lithium battery pack plays a crucial role in the manufacture of lithium-ion batteries, involving packaging, encapsulation, and assembly. This

Get a quote

Lithium Ion Battery Packaging: Soft Pack Design Guide

Soft-pack lithium-ion batteries have become a popular power source for electronics, electric vehicles, and energy storage systems. Thanks to their

Get a quote

Why Manufacturing Facilities Need Lithium Battery Packs for

Unlike traditional lead-acid batteries, lithium batteries are lighter, more efficient, and boast a longer lifecycle. Their adaptable configurations allow them to meet various

Get a quote

Battery Manufacturing-How We Build Your Custom

Looking for 18650 or 21700 lithium ion battery packs tailored to your needs? Whether it''s compact and lightweight packs for portable devices

Get a quote

Key Points of Lithium Battery PACK Manufacturing

Curious about how lithium batterypacks are made? Dive into the detailed process behind these essential energy storage solutions! From

Get a quote

How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

Get a quote

What budgets are needed when building a battery factory

Recently, many friends have asked us how to build 18650 battery pack, what are important factors about lithium ion battery assembly, what

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

Lithium-Ion Battery Packs: Leading OEM Manufacturer, Supplier, Factory

Get high-quality Lithium-Ion Battery Packs from the leading OEM Manufacturer, Supplier, and Factory. Choose reliable and durable battery solutions. Order now! Maximize your device''s

Get a quote

How To Assembly Cylindrical Battery Pack?

Battery pack spot welder is used to weld nickel sheets with many lithium batteries into a group pack, which is suitable for battery pack assembly in the factory for

Get a quote

Battery Factory How to Build the Lithium-Ion Battery

How to Build a Lithium-Ion Battery Pack? Lithium-ion battery pack mainly has two meanings. The first is the processing and assembly of

Get a quote

6 FAQs about [Pack lithium battery factory need ]

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is a lithium ion battery pack?

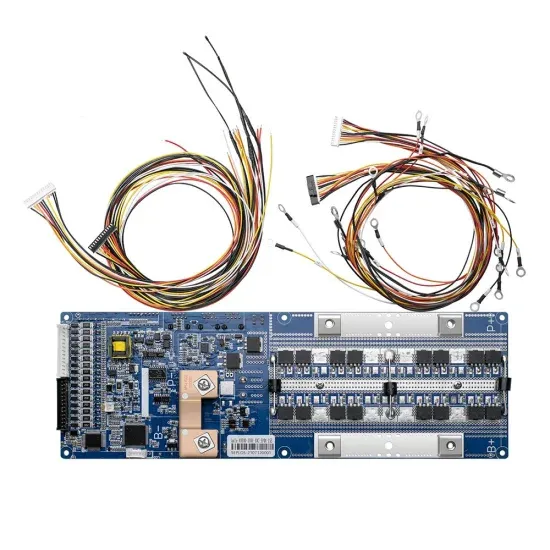

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

Why do custom lithium-ion batteries need a lifecycle mindset?

Once produced, properly supporting packs throughout service life is paramount: This lifecycle mindset maximizes the ROI of custom lithium-ion battery investments. Working with lithium-ion cells and batteries necessitates rigorous safety protocols given flammability risks if improperly handled.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

Guess what you want to know

-

Swiss quality lithium battery pack factory price

Swiss quality lithium battery pack factory price

-

Pack lithium battery factory design

Pack lithium battery factory design

-

Pack lithium battery factory customization

Pack lithium battery factory customization

-

Cote d Ivoire pack lithium battery factory

Cote d Ivoire pack lithium battery factory

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

Selling pack lithium battery factory

Selling pack lithium battery factory

-

Tajikistan professional lithium battery pack factory price

Tajikistan professional lithium battery pack factory price

-

Standard lithium battery pack factory price in Sierra Leone

Standard lithium battery pack factory price in Sierra Leone

-

North America pack lithium battery factory

North America pack lithium battery factory

-

OEM lithium battery pack for power station

OEM lithium battery pack for power station

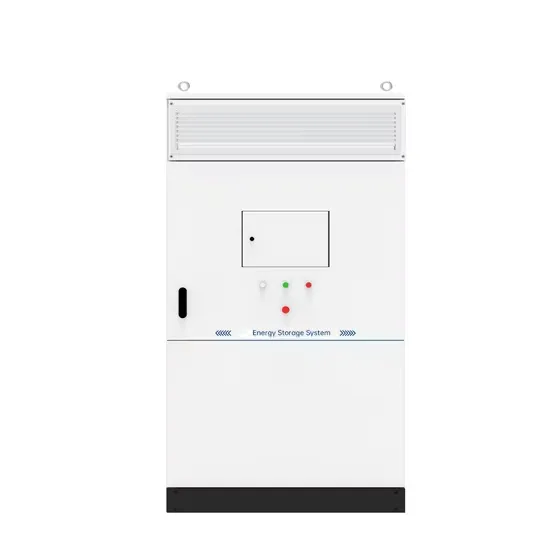

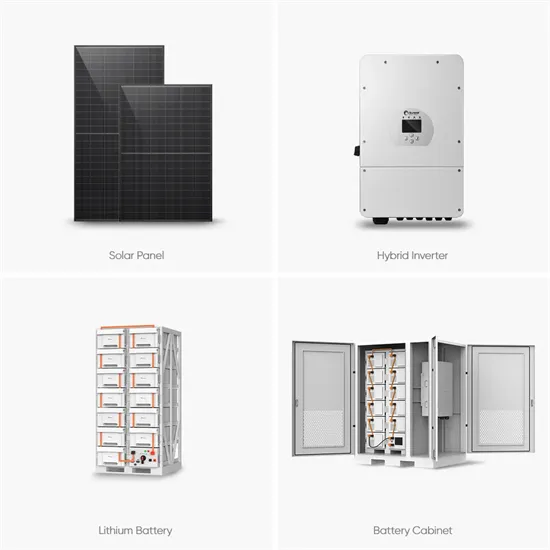

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.