How China''s CATL Makes an EV Battery

Contemporary Amperex Technologies or CATL is China''s leading EV battery supplier. As of this writing, it is the only Chinese EV battery company that has begu...

Get a quote

Quality Lifepo4 Battery Powerwall & High Voltage Battery factory

China leading provider of Lifepo4 Battery Powerwall and High Voltage Battery, Dongguan Funpack Elec Co., Ltd. is High Voltage Battery factory.

Get a quote

Battery Manufacturing Process: Materials, Production

Discover the battery manufacturing process, from material selection to final testing. Learn about advancements that improve efficiency and

Get a quote

Native Instruments Battery 4: Basics + using Expansions 2021!

Battery is still a great virtual instrument, and can do a lot of things Maschine can, as well as using the great sounds in NI''s Expansions packs! Here for the Cyber Sale 2021!

Get a quote

What Is A Battery Pack?

A battery pack is an integrated assembly of electrochemical cells, management systems, and structural components designed to store and deliver electrical energy. Using chemistries like

Get a quote

Battery Cell Manufacturing Process

Battery Cell Manufacturing Process In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery

Get a quote

Vingroup starts construction on EV Battery

The entire infrastructure of the factory, including a casting shop, a welding shop, and a packaging (battery pack) shop, is designed to produce

Get a quote

Advanced New Energy Lithium Battery PACK

Lithium battery assembly, Automated production line, Battery pack manufacturing, New energy battery, Industry 4.0, Smart manufacturing, High-precision

Get a quote

Battery Pack Manufacturing Process: Step-by-Step

Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get a quote

About

Overview Tata AutoComp and Gotion, China, have entered into a Joint Venture to Design, Manufacture, Supply and Service Li-ion Battery Packs for Electric Vehicles in India Gotion

Get a quote

Battery Pack Manufacturing Process

In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations. Whether you''re a

Get a quote

Battery Module & Pack Manufacturing: Step-by-Step

As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated quality control are the keys to scaling

Get a quote

Battery Production Flyer: Lithion Ion Cell Production

Battery Module and Pack Assembly Process The publication "Battery Module and Pack Assembly Process" provides a comprehensive process overview for the production of battery modules

Get a quote

Battery Module & Pack Manufacturing: Step-by-Step

As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated

Get a quote

Electric Forklift Parts Battery Units DPZ210A, Battery Pack

Hanzhi: China professional manufacturers and suppliers of electric forklift parts battery units dpz210a, battery pack 24v/210a, good quality. You can buy customized Start Battery made in

Get a quote

The iPhone Air looks incredible – but you''ll want that battery pack

2 days ago· The iPhone Air is finally official and Apple''s new ultra-thin phone looks incredible. However, there''s a few catches, and you''ll definitely need the new battery pack.

Get a quote

EV Battery-Pack Manufacturing Packs | DigiKey

This article reviews the complexities of EV battery packs and some related subassemblies, including the need for numerous battery cell modules,

Get a quote

Battery Pack Manufacturing Process: Step-by-Step Guide

Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get a quote

Battery Manufacturing In India

Given the nascency of the Indian battery manufacturing landscape, however, there are significant challenges which need to be overcome, and potential opportunities to be

Get a quote

Verkor l Batteries. Now. For the future. l Production de batteries

Verkor is building the biggest gigafactory in Europe to fast-track the manufacture of low-carbon batteries for a decarbonised future.

Get a quote

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will allow you to understand some of the

Get a quote

EV Battery-Pack Manufacturing Packs | DigiKey

This article reviews the complexities of EV battery packs and some related subassemblies, including the need for numerous battery cell modules, electrically efficient and

Get a quote

Unveiling the Battery Pack Manufacturing Process

Introduction The manufacturing of batteries is a meticulous process, involving several crucial stages that culminate in the creation of a

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will

Get a quote

Battery Manufacturing Process: Materials, Production & Test

Discover the battery manufacturing process, from material selection to final testing. Learn about advancements that improve efficiency and sustainability.

Get a quote

6 FAQs about [Pack Battery Factory Introduction]

What is the battery pack manufacturing process?

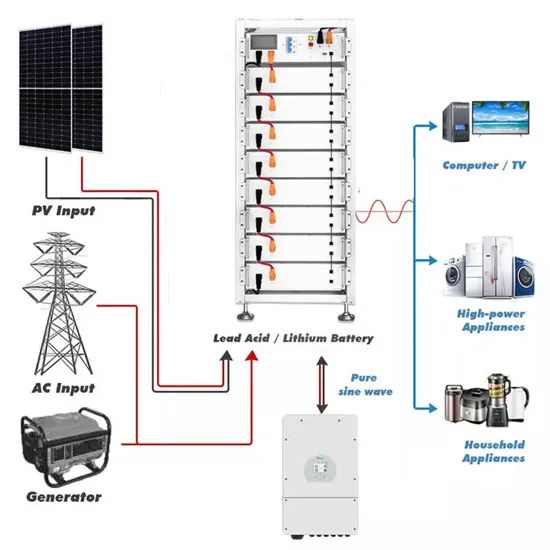

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

How to make a battery pack?

The journey towards crafting a battery pack begins with assembling individual battery cells. These cells, having undergone the transformation process to optimize their electrical performance, are now ready to be connected. Before this, it is essential to clean the surface of the cells thoroughly.

How is Industry 4.0 transforming battery pack manufacturing?

Manufacturing innovations are revolutionizing production efficiency: Industry 4.0 integration enables real-time monitoring and adaptive process control throughout battery pack assembly, significantly reducing defect rates while improving traceability. Emerging technologies will transform battery pack manufacturing:

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

How do I engineer a battery pack?

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will allow you to understand some of the limitations of the cells and differences between batches of cells. Or at least understand where these may arise.

Guess what you want to know

-

Pack lithium battery factory design

Pack lithium battery factory design

-

Swiss quality lithium battery pack factory price

Swiss quality lithium battery pack factory price

-

Cote d Ivoire pack lithium battery factory

Cote d Ivoire pack lithium battery factory

-

Standard lithium battery pack factory price in Sierra Leone

Standard lithium battery pack factory price in Sierra Leone

-

Introduction to Uzbekistan s solar lithium battery pack

Introduction to Uzbekistan s solar lithium battery pack

-

Ireland pack battery factory

Ireland pack battery factory

-

Pack battery factory level

Pack battery factory level

-

Pack lithium battery factory need

Pack lithium battery factory need

-

Benin lithium battery pack supplier factory

Benin lithium battery pack supplier factory

-

Low temperature lithium battery pack service introduction

Low temperature lithium battery pack service introduction

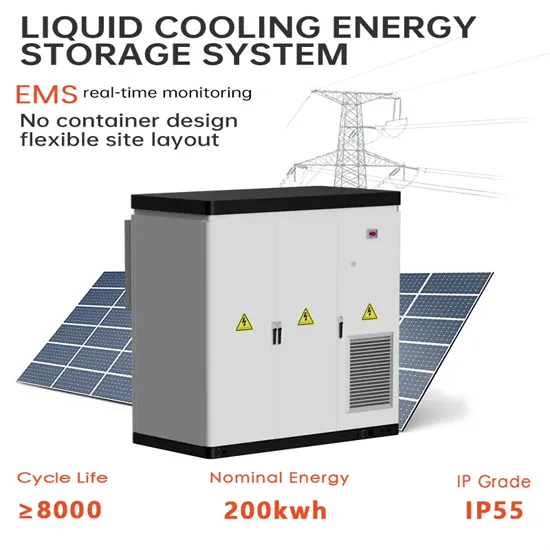

Industrial & Commercial Energy Storage Market Growth

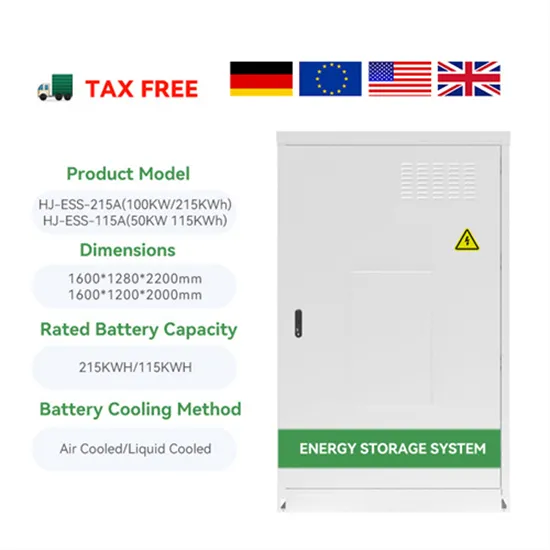

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

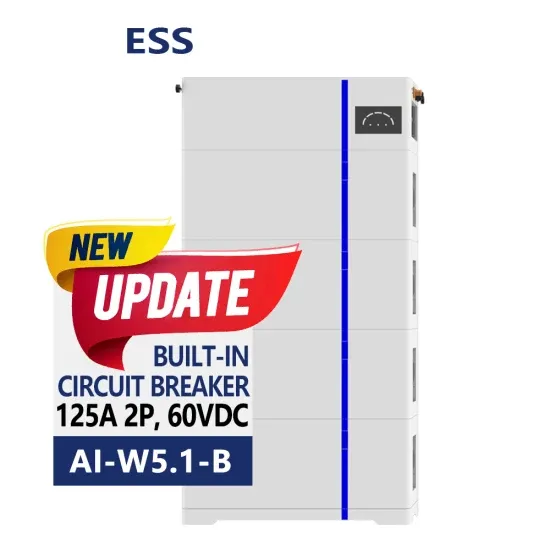

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.