The Differences Between 24v and 48v Inverter: Which

Are you confused about choosing between 24V and 48V inverters? Compare the key differences in efficiency, cost, and battery configuration.

Get a quote

Matching 36v solar panels to 48v inverter with build in MPPT

I believe the poster of this message has given information that can damage equipment or cause harm. 2 panels with a Voc 56.8v = 113.6v this is DANGEROUSLY close to

Get a quote

Pure Sine Wave Inverter (12v/24v/48v) | inverter

150W pure sine wave inverter adopts aluminum shell, makes the true sine inverter sturdier and helps it dissipate heat, which means it lasts longer. 48V DC to AC

Get a quote

The Differences Between 24v and 48v Inverter: Which is Better?

Are you confused about choosing between 24V and 48V inverters? Compare the key differences in efficiency, cost, and battery configuration.

Get a quote

Solar DC power system voltage choice 12V, 24V, 48V?

If you''re going to run your entire rig on AC (some people do), 48v can make the most sense because of the efficiency boost. Even if it''s mostly AC with just a couple of DC

Get a quote

Considerations when buying and installing an inverter

Basically, an inverter converts 12v/24v/36v/48v DC to 120v or 240v AC. For most of this article we discuss 12v because they are the most

Get a quote

Solar DC power system voltage choice 12V, 24V, 48V?

If you''re going to run your entire rig on AC (some people do), 48v can make the most sense because of the efficiency boost. Even if it''s mostly AC with just a couple of DC things, it might

Get a quote

48V Inverter vs. 12V Inverter: Core Differences and

When you''re choosing an inverter for home backup power, RV power, or an off-grid solar system, the choice between 48V and 12V can be

Get a quote

48 volt vs. 36 volt

48 volt is the right choice. 48 volt inverters are easy to find as it is a common voltage and will be less expensive watt for watt than 36 volt inverters and equipment. 48 volts

Get a quote

12V, 24V, or 48V Solar Power System: Which Voltage Is Best for

Compare 12V, 24V, and 48V solar systems to find your perfect fit. Our guide helps you maximize efficiency and avoid costly mistakes for your unique power needs.

Get a quote

The Best 36 Volt Power Inverters | SolarKnowHow

Your inverter should match the DC voltage of your battery or solar system—e.g., 36 V input for a 36 V battery bank. Mismatches can cause poor performance or damage. Try to operate your

Get a quote

Can I Replace a 36V Battery with a 48V Battery? An In

Understanding Voltage Differences: 36V vs. 48V Batteries Voltage and Performance Voltage is a critical factor in determining the performance of any electrical device.

Get a quote

Why You Should Not Use a 36V Battery on a 48V Ebike

What Happens If You Use a 36V Battery on a 48V Ebike? When you use a 36V battery on a 48V ebike, the bike will likely experience severe underperformance. The motor is

Get a quote

Considerations when buying and installing an inverter

Basically, an inverter converts 12v/24v/36v/48v DC to 120v or 240v AC. For most of this article we discuss 12v because they are the most common, but please see the chapter at

Get a quote

Batteries and inverter question

Page 1 of 2 1 2 > > > Batteries and inverter question « Previous Thread | Top | Next Thread » Similar Threads Thread Forum 96 fairway villager inverter Gas Club Car How bigs

Get a quote

Using a 36v battery with a 48v rear hub kit? : r/ebikes

Motors don''t really have voltages. They''re rated for certain voltages because of the power rating. For example 1000W of input at 48V requires only 21A, while 1000W of input at 36V would be

Get a quote

What can I do for home battery system using 36v batteries?

You might be able to use a 60V inverter. I use one directly with solar panels. 72V is within their range. 60V systems have some popularity in Europe.

Get a quote

eBike lithium batteries can hold an insane amount of

eBike lithium batteries can hold an insane amount of power. Has anyone thought about using them for emergency backup power? They should easily be able to

Get a quote

What Happens If You Put 48V to a 36V Motor?

Motors designed for 36V systems are not equipped to handle the increased voltage, which can lead to excessive heat generation. This overheating can cause permanent

Get a quote

52v and 48v battery usable on 36v system? : r/ebikes

Converting an cargobike to electric with a 36V dualdrive system. I have multiple 52v and 48v batteries from another ebike, would be nice if I can use

Get a quote

I Tested the Power of a Golf Cart Power Inverter

Discover the convenience and power of a Golf Cart Power Inverter. I tested it out on the course and was blown away by its efficiency. Upgrade your golfing experience today!

Get a quote

The Best 36 Volt Power Inverters | SolarKnowHow

Your inverter should match the DC voltage of your battery or solar system—e.g., 36 V input for a 36 V battery bank. Mismatches can cause poor performance

Get a quote

Differences Between 12V, 24V and 48V Inverter Systems

Learn the differences between 12V, 24V and 48V Inverter Systems with this handy guide from The Inverter Store and complete your off-grid power system today.

Get a quote

What Happens If You Put 48V to a 36V Motor?

In the realm of electric vehicles, including e-bikes and golf carts, understanding the relationship between voltage and motor compatibility is crucial. When you introduce a 48V

Get a quote

Solar DC power system voltage choice 12V, 24V, 48V?

The voltage coming off the panels needs to be higher than the system''s operational nominal voltage, ie you can use a single 12v nominal panel or multiple panels in parallel for a 12v

Get a quote

6 FAQs about [Can a 48V inverter be used with 36V voltage ]

What is a 48 volt inverter?

[48v Inverter] Transfer 48 volt DC to 230/240 volt AC, 50Hz frequency, standard UK plug. [inverter with LED display] Dual Intelligent temperature control cooling fan. LED displays let you know the working status all the time! [home inverter&car inverter] Widely used for camping, RV, truck, car, off-grid solar power system and home use appliance.

Do I need a 12V or 48V inverter?

Simply put, if you have a 12V system, you need a 12V inverter; a 48V system requires a 48V inverter. Standard Pure Sine Wave inverters simply change DC power to AC power. Inverter Chargers handle this function plus allow you to charge your batteries off shore power or a generator. Renogy’s 3500W Solar Inverter Charger is designed for a 48V system.

Can a 48 volt inverter run a battery?

When you use a 48-Volts inverter, you can use regular and more flexible connectors to connect the inverter to the battery bank. This is so because the thinner the wire, the higher the resistance. And if your DC voltage is lower, you will pass more current through the wires, and they can get very hot, and you lose a lot of battery power.

Should I use a 24 volt or 48 volt inverter?

I suggest you use A 24-volt inverter or 36-volt inverter or 48-volt inverter when you need to power appliances over 3000 Watts. You may decide to use them even for appliances that are 2000Watts. When you use a 48-Volts inverter, you can use regular and more flexible connectors to connect the inverter to the battery bank.

Can a 48v battery run a 36V motor?

Overheating and Damage: The primary risk of using a 48V battery with a 36V motor is overheating. Motors designed for 36V systems are not equipped to handle the increased voltage, which can lead to excessive heat generation. This overheating can cause permanent damage to the motor’s windings and bearings, reducing its lifespan significantly.

What is a good 36 volt inverter?

WZELB makes a 2,000 and 5,000W, 36-volt inverter. It comes with cables, a replacement fuse, and numerous safety features, such as overload, overvoltage, short circuit shutdowns, etc. This inverter is flexible and easy to use, with 2xAC outlets, a digital display, and a terminal block for hard wiring. WZELB makes a very good 36-volt inverter.

Guess what you want to know

-

Can a 48v inverter be used for 36v

Can a 48v inverter be used for 36v

-

60v inverter can be used in 48v power supply

60v inverter can be used in 48v power supply

-

Universal dual voltage 48v 60v inverter

Universal dual voltage 48v 60v inverter

-

Can a 38v lithium battery be used with a 48v inverter

Can a 38v lithium battery be used with a 48v inverter

-

The voltage used by the inverter is too high

The voltage used by the inverter is too high

-

Can a small 48V inverter be used

Can a small 48V inverter be used

-

12V 48V Voltage Inverter

12V 48V Voltage Inverter

-

36v inverter What is the minimum operating voltage

36v inverter What is the minimum operating voltage

-

Can a single 12v be used as an inverter

Can a single 12v be used as an inverter

-

What is the inverter s continuous output voltage

What is the inverter s continuous output voltage

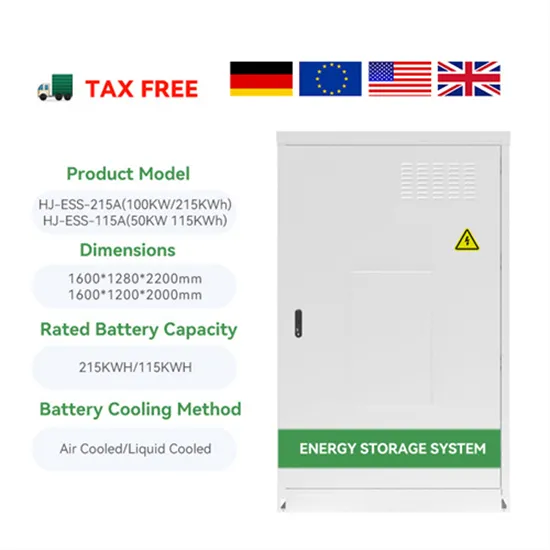

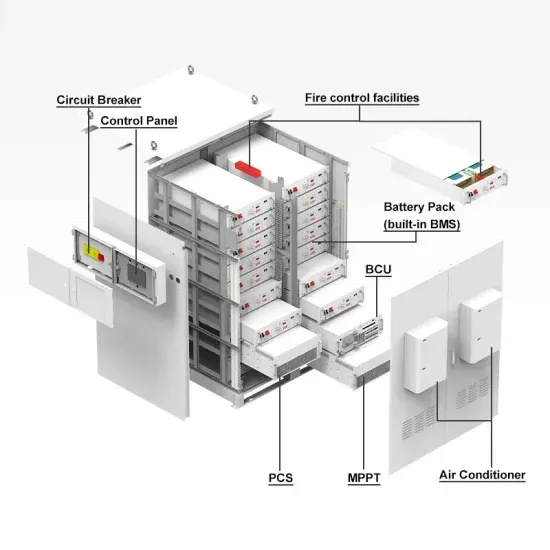

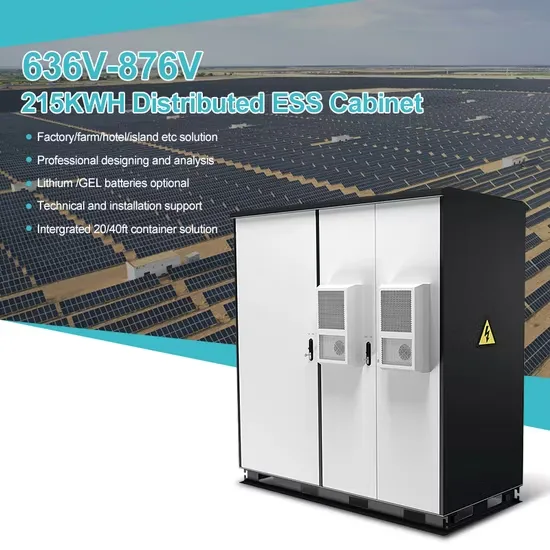

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.