48 volt vs. 36 volt

48 volt is the right choice. 48 volt inverters are easy to find as it is a common voltage and will be less expensive watt for watt than 36 volt inverters and equipment. 48 volts

Get a quote

Can I Replace a 36V Battery with a 48V Battery? An In-Depth

Understanding Voltage Differences: 36V vs. 48V Batteries Voltage and Performance Voltage is a critical factor in determining the performance of any electrical device.

Get a quote

The Differences Between 24v and 48v Inverter: Which is Better?

Are you confused about choosing between 24V and 48V inverters? Compare the key differences in efficiency, cost, and battery configuration.

Get a quote

36 Volts Through A 24 Volt Motor?

I''d to 36v change the entire system to 36v. 48v controller wont work for anything less than 48v. Because when the controller sees there is not enough voltage it shuts down to

Get a quote

When to Use a 24V or 48V Battery System Instead of a 12V System

When to Use a 24V or 48V Battery System Instead of a 12V System In this article, we go over some key facts and give suggestions on what battery voltage you should build your power

Get a quote

Using a 36v battery with a 48v rear hub kit? : r/ebikes

Hey All, So I have a huge 36v Luna pack (24.5ah) that I love on my current 36v ebike. In fact, I use it for a lot of stuff. I have a whole 36v ecosystem running at my house. But I''d like to get a

Get a quote

Can I supply 40v to a 36v golf cart motor due to having 8v

If this is a temporary thing with spare parts you have on hand, you could use 3 8v batteries with a 12v battery to get to 36v. Then you don''t have to worry about over voltage.

Get a quote

eBike lithium batteries can hold an insane amount of

eBike lithium batteries can hold an insane amount of power. Has anyone thought about using them for emergency backup power? They should easily be able to

Get a quote

What size inverter do I need to charge an electric bike

By simply multiplying the voltage and ampere, you can determine the inverter size. For instance, if your battery is 48V and 10.4A, you require an inverter

Get a quote

The Differences Between 24v and 48v Inverter: Which

Are you confused about choosing between 24V and 48V inverters? Compare the key differences in efficiency, cost, and battery configuration.

Get a quote

Tips to Choose the Right Inverter for Homes: 12V or 24V

Choose the Right Inverter with the difference between 12V or 24V and their advantages: inverter efficiency, battery bank setup, cabling cost, and

Get a quote

Fuse recommendation for 48V Victron Inverter

Converting 12V system to 48V - 15,360Wh 300Ah battery equivalent wired to 1,820W Solar connected to a Victron Multiplus II 120V 48/3000/35-50 and a Victron

Get a quote

48V battery on a 36V motor? | Endless Sphere DIY EV Forum

On the 48V system that came from EM3EV, I got the Mac kit, and it looks like the controller (IRFB3077) can handle 36-52V . Does that give me the green light to hook up the

Get a quote

12V, 24V, or 48V Solar Power System: Which Voltage Is Best for

Compare 12V, 24V, and 48V solar systems to find your perfect fit. Our guide helps you maximize efficiency and avoid costly mistakes for your unique power needs.

Get a quote

Considerations when buying and installing an inverter

Basically, an inverter converts 12v/24v/36v/48v DC to 120v or 240v AC. For most of this article we discuss 12v because they are the most

Get a quote

What is the cheapest way to upgrade to 36v system from 24v?

36v is a no go. There are virtually no inverters out there to choose from and even less solar charge controllers. While the scooter batteries seemed like a good deal, the reality is

Get a quote

Matching 36v solar panels to 48v inverter with build in MPPT

I''d have to say no. This panels don''t leave you any room for over voltage situations such as edge of cloud or cold temperatures. You need to run 2 in series to get the voltage high

Get a quote

Using a 36v battery with a 48v rear hub kit? : r/ebikes

Not work at all, because the controller will think that the 48V battery is "dead" at 36V, which is under the cut-off voltage for a 48V pack. As for the step-up-converter idea, that

Get a quote

Why You Should Not Use a 36V Battery on a 48V Ebike

Using a 36V battery on a 48V ebike is not recommended due to significant risks including underperformance, potential damage to electrical components, and safety hazards.

Get a quote

Using a 36v battery with a 48v rear hub kit? : r/ebikes

Not work at all, because the controller will think that the 48V battery is "dead" at 36V, which is under the cut-off voltage for a 48V pack. As for the step-up-converter idea, that probably won''t

Get a quote

48V Solar Power System Setup Guide: Using Hybrid Inverters for

In this case, the 48V system can operate at this power using a hybrid inverter and LiFePO₄ battery bank. There would be minimal heat loss and improved voltage stability. But to

Get a quote

Considerations when buying and installing an inverter

Basically, an inverter converts 12v/24v/36v/48v DC to 120v or 240v AC. For most of this article we discuss 12v because they are the most common, but please see the chapter at

Get a quote

What Happens If You Put 48V to a 36V Motor?

Overheating and Damage: The primary risk of using a 48V battery with a 36V motor is overheating. Motors designed for 36V systems are not equipped to handle the

Get a quote

Guess what you want to know

-

Can a 48v inverter be used for 36v

Can a 48v inverter be used for 36v

-

48v battery with inverter can be used for several hours

48v battery with inverter can be used for several hours

-

Can a small 48V inverter be used

Can a small 48V inverter be used

-

36V 48V Boost to 220V Universal Inverter

36V 48V Boost to 220V Universal Inverter

-

Make your own 36v to 220v inverter

Make your own 36v to 220v inverter

-

Lithium battery 48V 25A inverter

Lithium battery 48V 25A inverter

-

Energy storage inverter connected to 48v lithium battery

Energy storage inverter connected to 48v lithium battery

-

48v 200amp inverter

48v 200amp inverter

-

Is there a 60v and 48v inverter

Is there a 60v and 48v inverter

-

48v DC to dual 50v inverter

48v DC to dual 50v inverter

Industrial & Commercial Energy Storage Market Growth

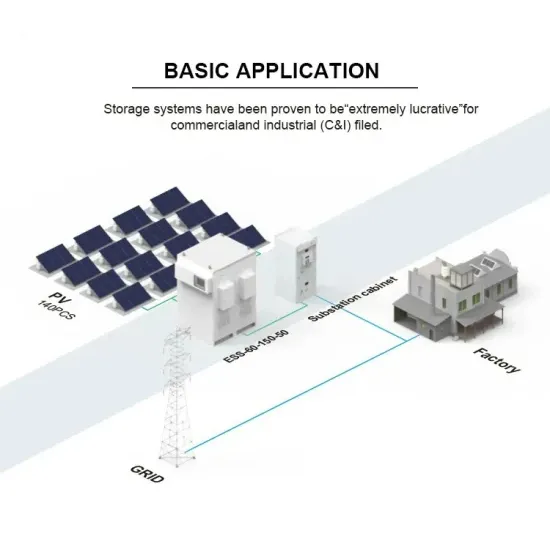

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

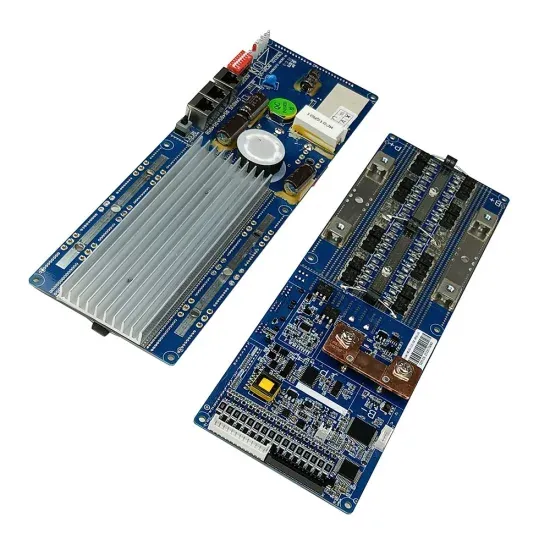

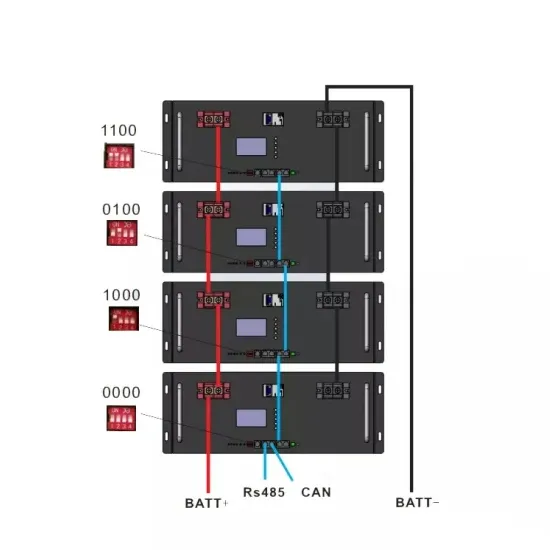

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.