Are Alkaline Battery Leaks Dangerous? Health Risks, Safety

Alkaline battery leaks occur when the internal components of an alkaline battery, typically potassium hydroxide, escape from the battery casing. This leakage often happens

Get a quote

Battery Technology for Data Centers and Network Rooms:

VRLA batteries in a cabinet should allow airflow around each battery container to allow removal of heat by convection or fan cooling. Avoid placing battery racks and/or cabinets near heat

Get a quote

Battery leak: is it toxic? This is what you should do

When a battery leaks, this is usually indicated by white deposits in the battery compartment of the electrical appliance. However, the leaking liquid does not pose a serious

Get a quote

Is the White Crusty Stuff on Batteries Dangerous?

In this article, I''ll talk about the white substance that forms on lead acid (wet cell) and dry cell (alkaline) batteries. I''ll look into its causes in both

Get a quote

Battery Technology for Data Centers and Network Rooms:

Although alternative energy storage technologies such as fuel cells, flywheels, lithium ion, and nickel cadmium batteries are being explored (see White Paper 65, Comparing Data Center

Get a quote

Battery leak: is it toxic? This is what you should do

When a battery leaks, this is usually indicated by white deposits in the battery compartment of the electrical appliance. However, the leaking

Get a quote

What are Alkaline Batteries? – BatteryGuy Knowledge Base

Alkaline batteries vs lithium Compared to lithium batteries, alkaline offers a higher voltage, giving off fast bursts of power to items such as camera flashes. However, both the

Get a quote

Is the White Crusty Stuff on Batteries Dangerous?

In this article, I''ll talk about the white substance that forms on lead acid (wet cell) and dry cell (alkaline) batteries. I''ll look into its causes in both battery types and examine its

Get a quote

What Is Battery Acid? Is Battery Acid Dangerous?

Yes, dried battery acid can leave behind corrosive salts, which can reactivate when exposed to moisture. If you see a white or crystalline residue around a battery, do not

Get a quote

What''s That White Stuff Leaking Out Of My Battery?

The white substance often seen in leaking batteries is primarily a result of chemical reactions occurring within the battery. This substance is not

Get a quote

What Gas Do Car Batteries Emit? – The Surprising Truth

Understanding what gases car batteries emit is essential for maintaining a safe and healthy environment, both for yourself and for the planet. Car batteries are electrochemical

Get a quote

What''s that white stuff on batteries? : r/NoStupidQuestions

Potassium Hydroxide when it''s inside the battery and Potassium Carbonate after it reacts with CO2 in the air after it leaks out. Both are irritants and you should be careful with it. It will

Get a quote

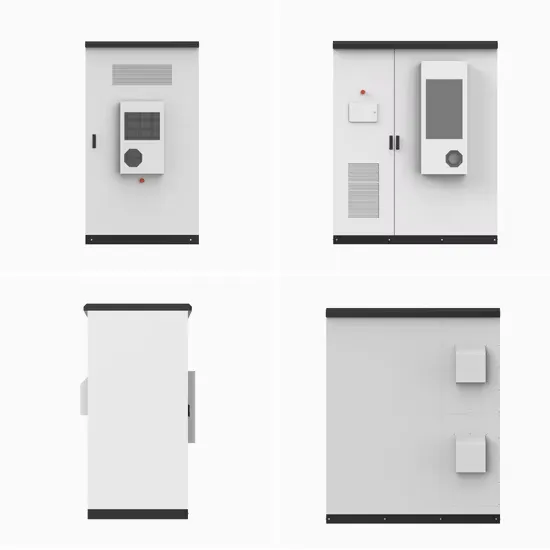

Battery Cabinets & Enclosures

Exponential Power''s Battery Cabinets & Enclosures provide durable, secure solutions for telecommunications and industrial applications. Designed to protect battery systems, these

Get a quote

Choosing the Right Battery Storage Cabinet: A

Lithium-ion batteries have become indispensable across countless industries, from logistics and warehousing to construction and renewable

Get a quote

Space Age Electronics, Inc.

When your professional installation requires battery backup storage compliant with NFPA 72 (1-5.2.9), the BCA is your ideal solution. With the ability to be

Get a quote

White Stuff on Battery-Safety, Care and Cleaning

Basically, the Potassium Hydroxide reacts with oxygen in the air to form this white compound, and it begins building up on the external part of the battery. It can also be

Get a quote

What''s That White Stuff Leaking Out Of My Battery?

The white substance often seen in leaking batteries is primarily a result of chemical reactions occurring within the battery. This substance is not inherently toxic but can be caustic,

Get a quote

Why do alkaline and carbon zinc batteries leak white

Alkaline batteries are very similar to carbon zinc batteries. They use manganese dioxide and metallic zinc as the reactive materials, but they use an alkaline potassium

Get a quote

Battery Corrosion: Why batteries leak and what do to when it

If too much gas develops, the battery cell ruptures, releasing the white sticky substance we call battery acid. Under regular use, an alkaline battery will not leak.

Get a quote

Why do alkaline and carbon zinc batteries leak white

Alkaline batteries are very similar to carbon zinc batteries. They use manganese dioxide and metallic zinc as the reactive materials, but they use an alkaline potassium

Get a quote

What''s that white stuff on batteries? : r/NoStupidQuestions

Potassium Hydroxide when it''s inside the battery and Potassium Carbonate after it reacts with CO2 in the air after it leaks out. Both are irritants and you should be careful with it.

Get a quote

Navigating the Unique Hazards of Lithium-Ion Batteries: Essential

Understanding Thermal Runaway Thermal runaway is an uncontrollable overheating process within lithium-ion batteries. It happens when a chemical reaction

Get a quote

Alkaline battery

An alkaline battery (IEC code: L) is a type of primary battery where the electrolyte (most commonly potassium hydroxide) has a pH value above 7. Typically, these batteries derive

Get a quote

Safely Store Batteries in Lithium-Ion Battery Charging

Justrite''s Lithium-Ion Battery Charging Cabinet is engineered to charge and store lithium batteries safely, mitigating common risks during charging.

Get a quote

Eaton-Battery-Handbook-BAT11LTA.PDF

The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically during storage to

Get a quote

Battery Corrosion: Why batteries leak and what do to when it

Discover how leaking alkaline battery damage can affect your devices and learn effective prevention and cleaning methods.

Get a quote

6 FAQs about [Battery cabinet batteries emit white alkali]

Do Alkaline Batteries leak?

Under regular use, an alkaline battery will not leak. Manufacturing defects can cause leakage, but by far, the most common reason for leaky batteries is a lack of use. When batteries sit in unused devices for long periods, hydrogen can build up in the battery cell until the pressure causes the battery’s insulating seals to breach.

What happens if you mix alkaline and lithium batteries?

Mixing alkaline, recyclable, and lithium batteries — or even the same kind of battery from different brands — results in whichever battery is strongest discharging faster, increasing the possibility of battery leakage. Remove batteries from any device you don’t use often.

Are alkaline batteries corrosive?

It is possible for the corrosive chemicals contained within batteries, particularly alkaline batteries, to deteriorate over time and seep through the casing of the battery, potentially causing damage to sensitive electronic components. This is especially true of alkaline batteries.

Are alkaline batteries toxic?

These substances are not toxic and can even be used in fertilizers. Alkaline batteries contain similar compounds, but they also have potassium hydroxide, which reacts with carbon dioxide in the air to form potassium carbonate. Although potassium hydroxide is corrosive, it’s absorbed into the battery components, reducing the risk of direct exposure.

What are alkaline batteries?

Alkaline batteries are a common type of battery that can be found in a wide variety of electronic devices, including flashlights, remote controls, and other similar items. They are made up of a paste that is potassium hydroxide, and they are encased in zinc.

Why do alkaline batteries build up?

Your battery type plays a key role in the formation of this build-up. Alkaline batteries are typically “dry cells” and do not rely on a liquid electrolyte. Instead, they employ a liquid potassium hydroxide solution that is absorbed into the reactive elements. As a result, there is no free-flowing liquid present.

Guess what you want to know

-

Which battery cabinet has the most durable batteries

Which battery cabinet has the most durable batteries

-

How to charge the batteries in a DC battery cabinet

How to charge the batteries in a DC battery cabinet

-

Does the battery cabinet produce batteries

Does the battery cabinet produce batteries

-

Distance between batteries in battery cabinet

Distance between batteries in battery cabinet

-

Battery cabinet batteries do not store electricity

Battery cabinet batteries do not store electricity

-

How to group batteries in a battery cabinet

How to group batteries in a battery cabinet

-

Battery Cabinet and System Safety Requirements

Battery Cabinet and System Safety Requirements

-

Lead-acid battery cabinet integrated system

Lead-acid battery cabinet integrated system

-

Is lithium battery better for Maldives inverters or lithium batteries

Is lithium battery better for Maldives inverters or lithium batteries

-

Dangerous Goods New Energy Battery Cabinet

Dangerous Goods New Energy Battery Cabinet

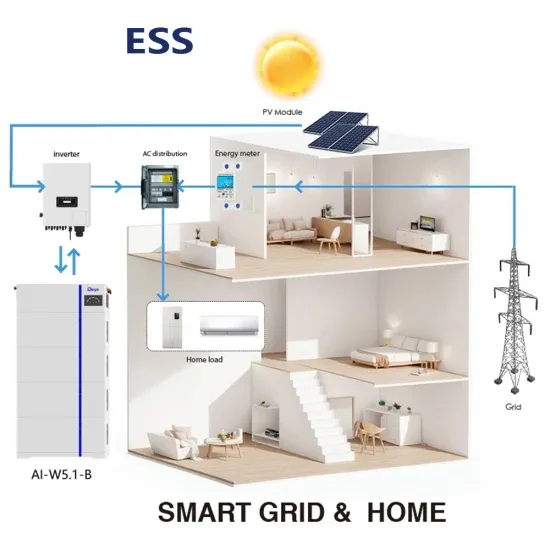

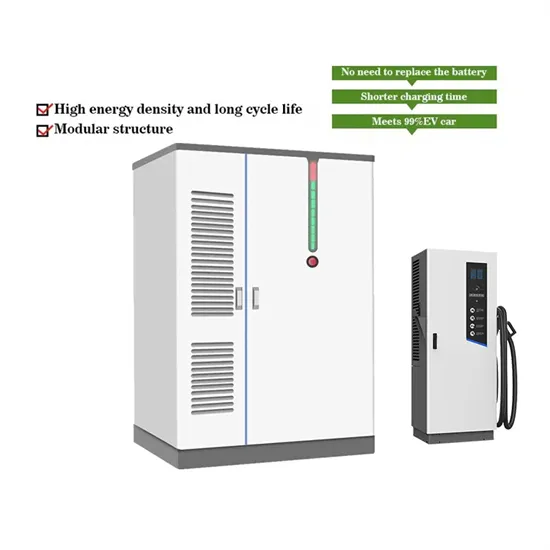

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.