480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get a quote

Minimum distance between A and B Batteries | Eng-Tips

But I haven''t seen any specific guidelines, it is left up to "good engineering." Five feet seems small. Maybe adding a barrier between the two batteries to prevent a common fire

Get a quote

Arc-in-a-Box: DC Arc Flash Calculations Using a Simplified

Abstract A method is proposed for calculating the incident energy and the arc flash boundary distance for dc systems when an arc is bounded inside a space such as a battery cabinet. The

Get a quote

Experimental and numerical investigation on thermal

In this paper, the flow field and temperature distribution inside an outdoor cabinet are studied experimentally and numerically. The battery cabinets house 24 batteries in two

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.)

Get a quote

VRLA Batteries Installation & Operation Guide

5. Batteries Installation 5.1 Unpack and check Check the packaging for signs of shipping damage. Unpack and check the appearance of battery for signs of

Get a quote

Where Should You Store Batteries – Safe Battery Storage | Justrite

Protect your people and property by learning how to safely store, charge and handle lithium-ion batteries used in the workplace.

Get a quote

Do Lithium Ion Batteries Require A Battery Room? Storage

In summary, lithium-ion batteries do not always require a dedicated battery room; however, proper storage requirements, including temperature, humidity, and ventilation, are

Get a quote

Work Space about battery racks | Information by Electrical

For a battery rack arranged one battery deep by any number of batteries wide and tall, all maintenance can be performed from one side of the rack - just like a switchboard or

Get a quote

Installation of Inverter and batteries outside

Installing the inverter and batteries in the bedroom is not a good idea, since apparently they make a noise? Installing the inverter and batteries

Get a quote

LI-ION BATTERY ENERGY STORAGE SYSTEMS:

As batteries age, their capacity fades not allowing the batteries to be fully charged due to the loss in capacity of the battery. However, lithium-ion batteries only lose 1⁄4 the amount of charge

Get a quote

Choosing the Right Battery Storage Cabinet: A

Discover essential considerations when selecting a battery storage cabinet for lithium-ion batteries. Learn about ventilation, fire safety,

Get a quote

Installation Procedure for UPS with Internal Batteries

Modular Battery Cabinets and Remote UPS Rated for Maximum 100 kW NOTE: The distance between the modular battery cabinet (s) and the UPS must not exceed 100 m. Contact

Get a quote

Spaces About Battery Systems | UpCodes

Spaces designated for battery systems must adhere to specific regulations regarding working space, which is measured from the battery cabinet''s edge. For battery racks, a minimum

Get a quote

IR N-3: Modular Battery Energy Storage Systems

PURPOSE This Interpretation of Regulations (IR) clarifies specific code requirements relating to battery energy storage systems (BESS) consisting of prefabricated modular structures not on

Get a quote

Installation Environment and Clearance Requirements

If a bottom cabling cabinet is configured, the customer needs to prepare a cable tray to support cables routed from the top. The distance between the bottom of the cable tray and the top of

Get a quote

Designing Industrial Battery Rooms: Fundamentals and Standards

Designing Industrial Battery Rooms: Fundamentals and Standards Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article

Get a quote

Understand the codes, standards for battery energy

Learning Objectives Understand the key differences and applications battery energy storage system (BESS) in buildings. Learn to

Get a quote

How important is the distance between batteries in

I''m planning a new solar + battery setup and would like to save as much space as possible. One idea I had was to "stack" 2 rows of batteries instead of lining

Get a quote

Safe distance as it applies to fire protection for battery charging

Facilities shall be provided to include fire protection and adequate ventilation based on the amount of batteries to be charged and/or stored. The safe distance thus would be

Get a quote

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

Get a quote

What is the appropriate safety distance between battery

Batteries themselves should be mounted on stands or in cabinets, designed to provide good access, particularly to prevent personnel responsible for servicing from having to

Get a quote

EG4 BESS Spacing

The following document clarifies BESS (Battery Energy Storage System) spacing requirements for the EG4 WallMount batteries / rack mount six slot battery cabinet installations.

Get a quote

Battery Energy Storage Systems: Main Considerations for Safe

This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Get a quote

6 FAQs about [Distance between batteries in battery cabinet]

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What are the requirements for a battery location?

Battery locations shall conform to 480.9 (A), (B), and (C). (A) Ventilation. Provisions appropriate to the battery technology shall be made for sufficient diffusion and ventilation of gases from the battery, if present, to prevent the accumulation of an explosive mixture. (B) Live Parts. Guarding of live parts shall comply with 110.27.

How do you store a battery?

Humidity is another critical factor. Ideal storage conditions should maintain humidity levels below 60% to prevent corrosion and damage. Batteries exposed to high humidity can develop rust or leaks, which are hazardous. It is also important to store batteries at a partial charge.

Where should a top terminal battery be installed?

Where top terminal batteries are installed on tiered racks, working space in accordance with the battery manufacturer’s instructions shall be provided between the highest point on a cell and the row or ceiling above that point. (E) Egress.

Guess what you want to know

-

How many batteries are in a micro-module battery cabinet

How many batteries are in a micro-module battery cabinet

-

Does the battery cabinet produce batteries

Does the battery cabinet produce batteries

-

How to charge the batteries in a DC battery cabinet

How to charge the batteries in a DC battery cabinet

-

How to install lithium batteries in battery cabinet

How to install lithium batteries in battery cabinet

-

Can the batteries in the battery cabinet be recharged

Can the batteries in the battery cabinet be recharged

-

How to group batteries in a battery cabinet

How to group batteries in a battery cabinet

-

Battery cabinet batteries emit white alkali

Battery cabinet batteries emit white alkali

-

Battery cabinet containing lithium batteries

Battery cabinet containing lithium batteries

-

How to remove batteries from the battery cabinet

How to remove batteries from the battery cabinet

-

Is there a battery cabinet factory in Algeria

Is there a battery cabinet factory in Algeria

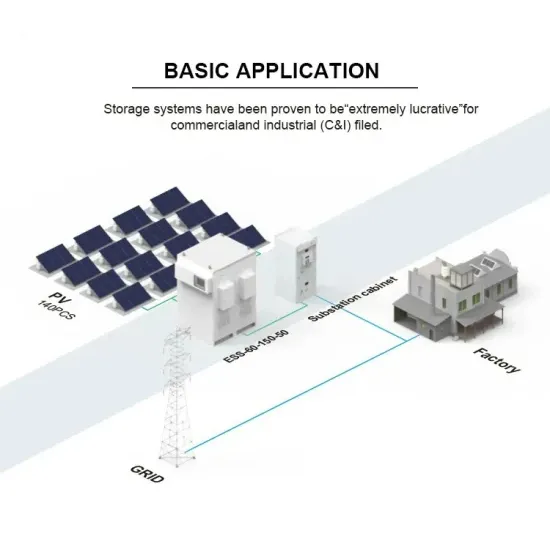

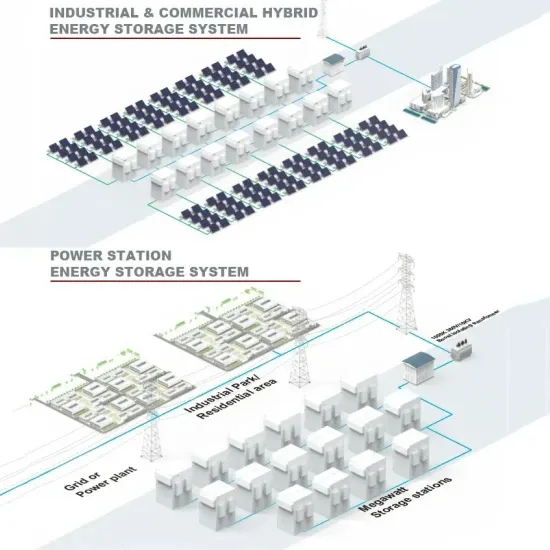

Industrial & Commercial Energy Storage Market Growth

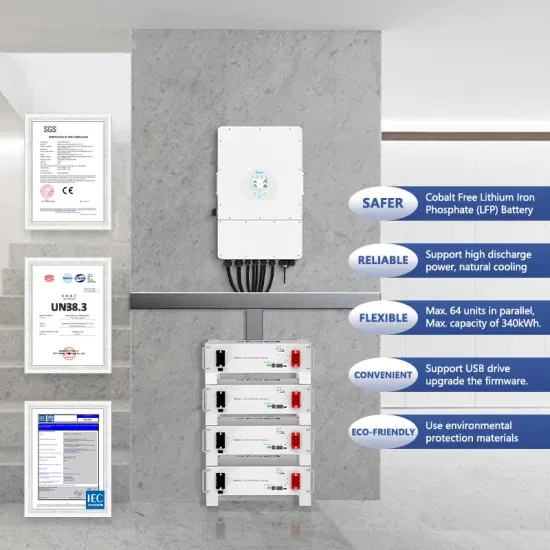

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

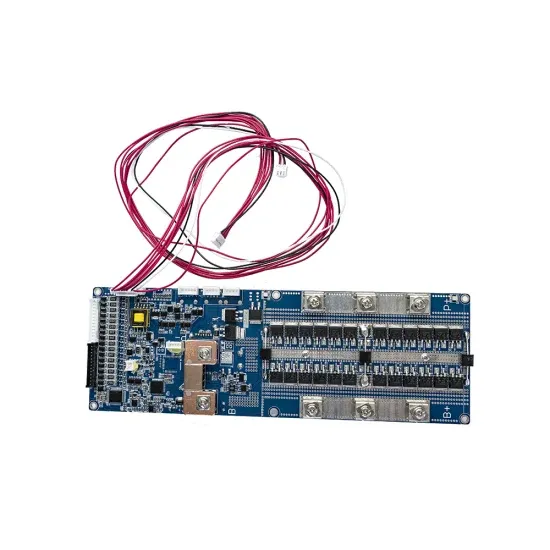

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.