What does the energy storage cabinet consist of? | NenPower

An energy storage cabinet''s battery systems are indeed the heart of this technology. Various types of batteries can be employed, each with distinguishable

Get a quote

How does a cabinet battery work?

How does a cabinet battery work?How does a cabinet battery work? Jun 30, 2025 Leave a message As a seasoned cabinet battery supplier, I''ve witnessed the growing curiosity

Get a quote

Lithium Battery Charging Cabinet: The Essential Guide to Safe

The widespread use of lithium-ion batteries across various industries and applications—ranging from power tools to electric vehicles—has led to increasing concern

Get a quote

MAN Advances Construction of Battery Production

It will produce up to 50,000 batteries annually in its first phase, with potential expansion to 100,000 batteries per year by 2030. Production

Get a quote

Eaton-Battery-Handbook-BAT11LTA.PDF

The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically during storage to

Get a quote

Understanding Lithium Ion Battery Storage Cabinets: Safety,

These cabinets are designed to safely store and charge lithium-ion batteries while minimizing fire and chemical hazards. A well-built cabinet provides thermal isolation, fire

Get a quote

The Future of Safe Energy Storage: Why Every Facility Needs a

Lithium-ion batteries are the power source of modern innovation—from electric vehicles and drones to medical devices and grid-scale energy systems. As battery adoption

Get a quote

MAN announces end of works at the company''s battery

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000 square metres. Up to 50,000

Get a quote

What Are Battery Rack Cabinets and Why Are They Essential?

Battery rack cabinets are secure, organized, and often climate-controlled enclosures designed to safely store, protect, and charge multiple batteries, especially lithium

Get a quote

Start of battery production in Nuremberg

Where the production of powerful diesel engines was once the main focus, there are now also batteries for electrically powered buses and trucks rolling off the production line.

Get a quote

MAN Advances Construction of Battery Production Facility in

It will produce up to 50,000 batteries annually in its first phase, with potential expansion to 100,000 batteries per year by 2030. Production methods such as laser welding

Get a quote

Start of battery production in Nuremberg

Where the production of powerful diesel engines was once the main focus, there are now also batteries for electrically powered buses and trucks rolling off the

Get a quote

MAN celebrates topping-out ceremony for new battery production

From April 2025, the delivered modules will be inserted into battery layers in large series production. These layers will be stacked on top of each other to form the battery pack and then

Get a quote

How do electric batteries work, and what affects their properties?

Electric vehicles use lithium ion batteries with small amounts of nickel, manganese and cobalt. How do they work and what chemistry affects their properties?

Get a quote

When Does Hydrogen Become a Risk in the Battery Room?

Is hydrogen a problem in your battery room? Forklift batteries release hydrogen while charging, and hydrogen is a flammable gas; in fact, hydrogen is listed as a class 4

Get a quote

The Ultimate Guide to Battery Charging Cabinets:

Understanding the Importance of Battery Charging Cabinets Lithium-ion batteries power many of our everyday devices, from industrial machinery to personal

Get a quote

Where are Tesla Batteries Made? Does Tesla Make

Tesla batteries are made in Japan, China, the United States, and South Korea (countries in red) The Chinese company CATL is the world''s

Get a quote

Lithium-Ion Batteries and Charging – Fire Risk

A 90-minute fire rating has been achieved from an international testing facility for our lithium-ion battery charging cabinets. Max 1006 degrees C was achieved

Get a quote

Battery Storage Cabinets: The Backbone of Safe and

Battery storage cabinets are integral to maintaining the safety and efficiency of lithium-ion batteries. They provide a controlled environment that

Get a quote

Battery Storage Cabinets: The Backbone of Safe and Efficient

Battery storage cabinets are integral to maintaining the safety and efficiency of lithium-ion batteries. They provide a controlled environment that mitigates risks associated

Get a quote

MAN announces end of works at the company''s

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000

Get a quote

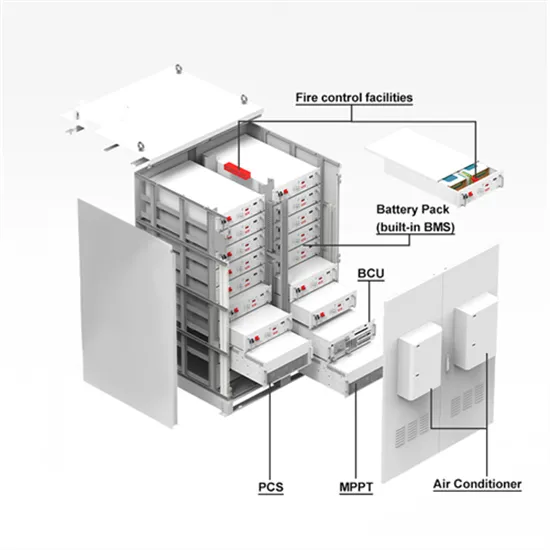

What does the energy storage cabinet consist of?

An energy storage cabinet''s battery systems are indeed the heart of this technology. Various types of batteries can be employed, each with

Get a quote

How do batteries work? A simple introduction

What is a battery? A battery is a self-contained, chemical power pack that can produce a limited amount of electrical energy wherever it''s

Get a quote

Nickel–cadmium battery

Thomas Edison patented a nickel– or cobalt–cadmium battery in 1902, [3] and adapted the battery design when he introduced the nickel–iron battery to the US two years after Jungner had built

Get a quote

The Role of Battery Cabinet Systems in Modern Energy Storage

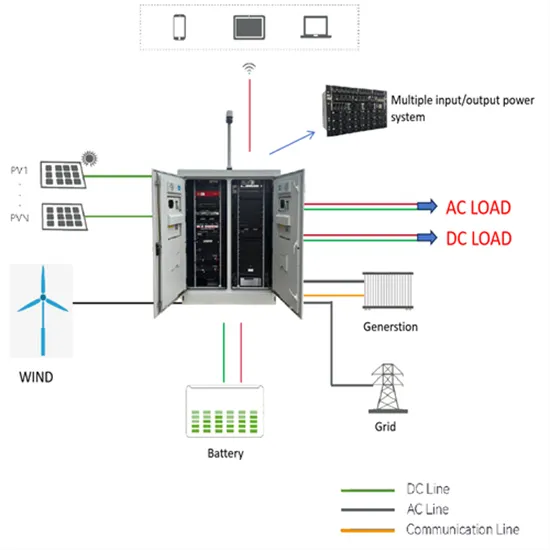

A battery cabinet system is an integrated assembly of batteries enclosed in a protective cabinet, designed for various applications, including peak shaving, backup power,

Get a quote

Unveiling the Wonders of Cabinet Batteries: A Comprehensive

Cabinet batteries, also known as battery cabinets, are self - contained units that house multiple battery cells or modules. They are designed to provide a convenient and

Get a quote

What Is a Battery Rack Cabinet and Why Is It Essential?

A battery rack cabinet combines modular design, structural durability, and ventilation systems to store batteries. It includes features like adjustable shelves, temperature

Get a quote

6 FAQs about [Does the battery cabinet produce batteries ]

What is a battery cabinet?

Battery cabinets are a convenient storage solution that encourages staff to maintain the correct handling and storage procedures. By charging and storing batteries in the one location, you are reducing the likelihood of batteries being lost, stolen, damaged or left in unsafe conditions (such as outdoors).

Why should you have a battery cabinet?

For example, dropping a battery or leaving it in a hot location can result in irreversible damage to the battery cell, which can lead to ignition or explosion. Providing a battery cabinet can reduce these risks by encouraging safe handling and storing practices within your team.

How many man batteries can be produced a year?

In the current expansion stage, 50,000 battery packs per year can be produced there, with a possible maximum of 100,000 units – the exact figure depends on the respective market situation. MAN uses NMC cell chemistry (nickel-manganese-cobalt) in its batteries, which has been specially adapted to the operation of commercial vehicles.

What makes man a state-of-the-art battery manufacturer?

But it is not just the batteries produced in Nuremberg that are state-of-the-art – the production process also boasts a technological highlight: MAN is implementing modular production – i.e. a system without a conveyor belt or cycle that can handle different product variants and be easily adapted to new variants.

How many batteries will be built in 2025?

Over 50 manual and automated assembly stations and seven test benches for quality assurance will be installed on an area of 17,000 square metres. The installation of the first production systems has already begun. From April 2025, up to 50,000 batteries per year will be built in an initial expansion phase.

Did the Bavarian Minister-President miss the start of battery production in Nuremberg?

Historic events deserve to be celebrated. And so, neither the Bavarian Minister-President Dr. Markus Söder nor the Bavarian Minister of Economic Affairs, Regional Development and Energy Hubert Aiwanger, missed the opportunity to attend the start of battery production in Nuremberg.

Guess what you want to know

-

How to install batteries in a battery cabinet

How to install batteries in a battery cabinet

-

Battery cabinet containing lithium batteries

Battery cabinet containing lithium batteries

-

Does the communication network cabinet produce base station batteries

Does the communication network cabinet produce base station batteries

-

Which battery cabinet has the most durable batteries

Which battery cabinet has the most durable batteries

-

Distance between batteries in battery cabinet

Distance between batteries in battery cabinet

-

What type of batteries does the uranium battery cabinet contain

What type of batteries does the uranium battery cabinet contain

-

Can the batteries in the battery cabinet be recharged

Can the batteries in the battery cabinet be recharged

-

DC screen battery cabinet integrated cabinet

DC screen battery cabinet integrated cabinet

-

Integrated battery cabinet manufacturer

Integrated battery cabinet manufacturer

-

Energy storage cabinet 9v battery photovoltaic

Energy storage cabinet 9v battery photovoltaic

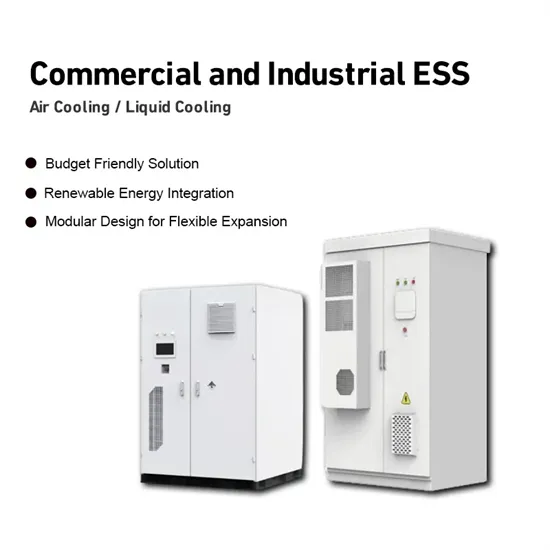

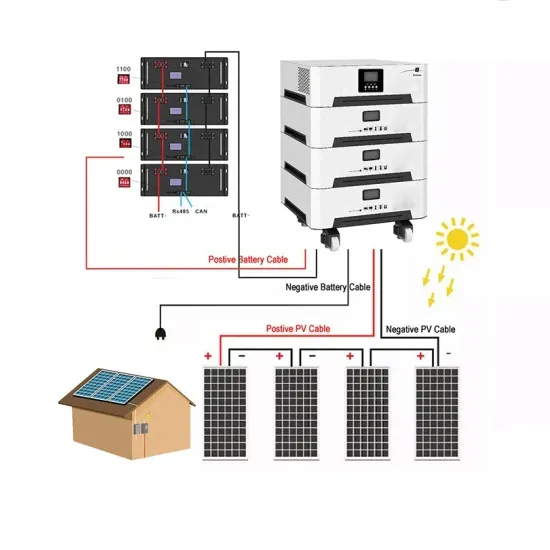

Industrial & Commercial Energy Storage Market Growth

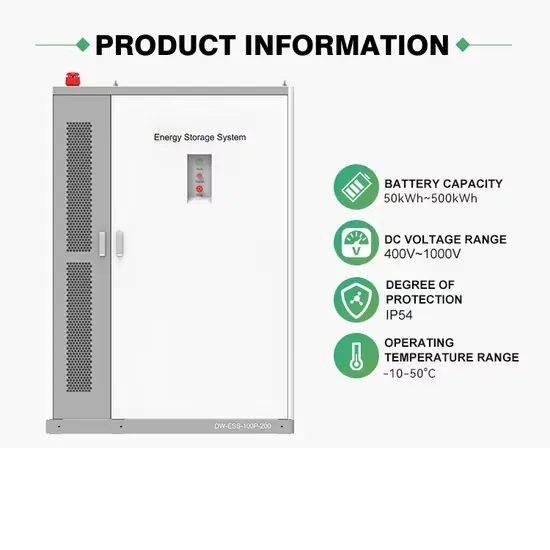

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.