Solar module manufacturing capacity could exceed 1.5 TW by

Global solar module manufacturing capacity is set to exceed 1.5 TW by 2035, according to forecasts from the IEA. Its latest report, " Energy Technology Perspectives 2024,"

Get a quote

Thin Film Photovoltaics Market Size, Share

Thin film photovoltaics market size was valued over USD 7.14 billion in 2023 and is estimated to grow at a CAGR of over 16.5% between 2024 and 2032, driven

Get a quote

Solar PV module market outlook 2025: emerging

GlobalData estimates that global thin-film module capacity will reach 26.69GW and a market value of $102.76bn in 2023. Considered second

Get a quote

India''s Solar Module Manufacturing Capacity Exceeds

Of the total capacity, India added 20.8 GW solar module and 3.2 GW cell manufacturing in CY 2023. A majority or 60% of this is equipped to

Get a quote

PHOTOVOLTAIC MODULES AND INVERTERS

The solar cell and module manufacturing capacity in the United States and India is forecasted to triple in the coming years. However, the cost of manufacturing cells and modules in these

Get a quote

IEA: Global photovoltaic module production capacity will exceed

According to the International Energy Agency (IEA), global solar panel production capacity will exceed 1.5TW by 2035. Its latest report, Energy Technology Outlook 2024,

Get a quote

Data and Tools | Photovoltaic Research | NREL

PVWatts Calculator Estimates energy production and costs of grid-connected PV systems. Thin-Film Solar Cell Current Voltage and Time-Resolved Photoluminescence

Get a quote

First Solar, Inc., Why Invest

First Solar''s thin film PV technology produces energy-efficient modules with a superior degradation rate, temperature coefficient, spectral and shading response, and the smallest

Get a quote

Global solar module production shares by technology| Statista

Thin film solar modules held a share of two percent of the total production. The production of solar photovoltaic modules worldwide reached approximately 612 gigawatts in 2023.

Get a quote

CdTe-based thin film photovoltaics: Recent advances, current

Cadmium telluride (CdTe) thin-film PV modules are the primary thin film product on the global market, with more than 30 GW peak (GWp) generating capacity representing many

Get a quote

Global PV module manufacturing to reach 1.8TW in 2025 – report

Australian thinktank Climate Energy Finance (CEF) has forecast global solar module manufacturing capacity to reach 1.8TW by the end of the year. This would be triple the

Get a quote

Photovoltaics Report

In 2024, approximately 96% of solar modules and their components came from Asia, primarily from China with a module production share of about 80%, which also controls more than 95%

Get a quote

First Solar plans to double manufacturing capacity by

Year-end 2026, the company expects to have 14 GW of U.S. solar capacity and 11 GW internationally, reaching 25 GW of global solar module

Get a quote

Sharp Launches Mass Production of 2nd-Generation

Sharp''s aim is to develop production technologies and accumulate know-how based on this production line and establish a production system at

Get a quote

Thin Film Photovoltaics Market Size, Share & Forecasts

Thin film photovoltaics market size was valued over USD 7.14 billion in 2023 and is estimated to grow at a CAGR of over 16.5% between 2024 and 2032, driven by technological innovation

Get a quote

PHOTOVOLTAIC MODULES AND INVERTERS

For Si-based technology modules, ingot manufacturing or wafer production is identified as having the highest environmental impact contribution while for thin-film technology modules, the metal

Get a quote

Beyond silicon: Thin-film tandem as an opportunity for photovoltaics

The latter results, combined with established thin-film R&D centers and equipment suppliers in the EU and the USA [26], may provide an opportunity to build new thin-film

Get a quote

Solar PV manufacturing capacity and production by

Solar PV manufacturing capacity and production by country and region, 2021-2027 - Chart and data by the International Energy Agency.

Get a quote

CdTe Perspective Paper

Purpose This document describes the state of cadmium telluride (CdTe) photovoltaic (PV) technology and then provides the perspective of the U.S. Department of

Get a quote

Fall 2024 Solar Industry Update

Though thin-film PV represented around 3% of global PV deployed from 2015 through 2023, it accounted for more than 17% of U.S. PV deployments during this period (24% of utility-scale

Get a quote

Solar Photovoltaic Manufacturing Basics

Those systems are comprised of PV modules, racking and wiring, power electronics, and system monitoring devices, all of which are manufactured. Learn how PV works. Read the Solar

Get a quote

Solar PV module market outlook 2025: emerging trends and

GlobalData estimates that global thin-film module capacity will reach 26.69GW and a market value of $102.76bn in 2023. Considered second-generation solar cells, thin-film cells

Get a quote

Solar module manufacturing capacity could exceed

Global solar module manufacturing capacity is set to exceed 1.5 TW by 2035, according to forecasts from the IEA. Its latest report, " Energy

Get a quote

The Global Thin Film Photovoltaics Market 2025-2035

Thin film photovoltaics are solar cells manufactured by depositing one or more thin layers of photovoltaic material onto a substrate. Unlike conventional crystalline silicon solar cells, which

Get a quote

Solar PV manufacturing capacity and production by country and

Solar PV manufacturing capacity and production by country and region, 2021-2027 - Chart and data by the International Energy Agency.

Get a quote

Global PV module manufacturing to reach 1.8TW in

Australian thinktank Climate Energy Finance (CEF) has forecast global solar module manufacturing capacity to reach 1.8TW by the end of the

Get a quote

First Solar CdTe modules could add US$10 billion to

First Solar''s decision to focus on module production puts in a strong position going in to 2024. Credit: First Solar. Thin-film solar

Get a quote

6 FAQs about [Global thin-film photovoltaic module production capacity]

What is the global solar module manufacturing capacity?

Image: International Energy Agency Global solar module manufacturing capacity is set to exceed 1.5 TW by 2035, according to forecasts from the IEA. Its latest report, “ Energy Technology Perspectives 2024,” covers the production of solar, wind turbines, electric cars, batteries, electrolyzers, and heat pumps.

What is thin film photovoltaic (PV)?

Introduction Thin film photovoltaic (PV) technologies often utilize monolithic integration to combine cells into modules. This is an approach whereby thin, electronically-active layers are deposited onto inexpensive substrates (e.g. glass) and then interconnected cells are formed by subsequent back contact processes and scribing.

Does China still dominate the global solar PV module market?

China continues its dominance of the global solar PV module market. Declining costs of PV module production have made solar installations more affordable globally. Source: abriendomundo/Shutterstock.com.

Are CdTe solar modules the highest production thin film photovoltaic technology?

Herein we have reviewed the developments in the cell technology that has enabled CdTe solar modules to emerge as the highest-production thin film photovoltaic technology.

What is the growth rate of photovoltaics?

Please send any comments or suggestions for improvement to both [email protected] and [email protected] Photovoltaics is a fast-growing market: The Compound Annual Growth Rate (CAGR) of cumulative PV installations was about 27% between the years 2014 and 2024. Wafer size increased.

How much power does a PV module produce?

Keeping the same number of cells, larger PV module sizes are realized, allowing a power range of over 700 W per module. In 2024, Europe’s contribution to the total cumulative PV installations amounted to 23%. In contrast, installations in China accounted for 49% (in 2023 43%) and in North America for 5% respectively.

Guess what you want to know

-

Thin-film photovoltaic module production

Thin-film photovoltaic module production

-

Thin-film photovoltaic module subsidies

Thin-film photovoltaic module subsidies

-

Malaysian thin-film photovoltaic module manufacturer

Malaysian thin-film photovoltaic module manufacturer

-

Rooftop thin-film photovoltaic module price

Rooftop thin-film photovoltaic module price

-

Solar photovoltaic module production in Luxembourg

Solar photovoltaic module production in Luxembourg

-

Photovoltaic cell module single-piece capacity

Photovoltaic cell module single-piece capacity

-

Thin-film photovoltaic module structure

Thin-film photovoltaic module structure

-

Grenada monocrystalline photovoltaic module panels

Grenada monocrystalline photovoltaic module panels

-

Huawei Timor-Leste photovoltaic module project

Huawei Timor-Leste photovoltaic module project

-

China s unlisted photovoltaic module projects

China s unlisted photovoltaic module projects

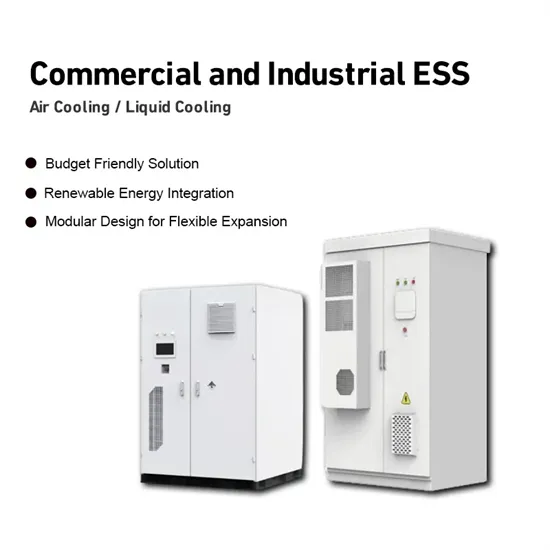

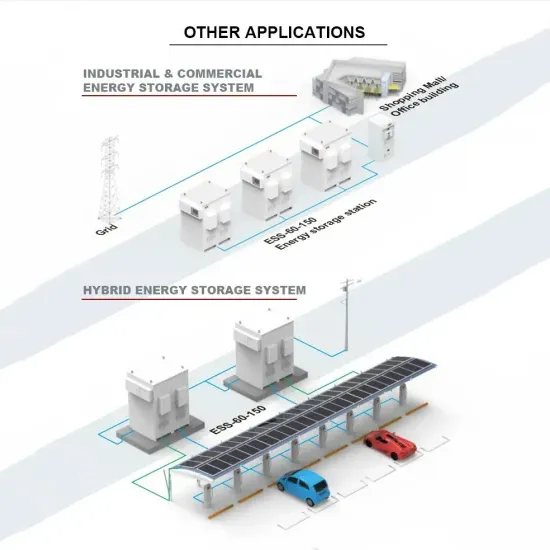

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

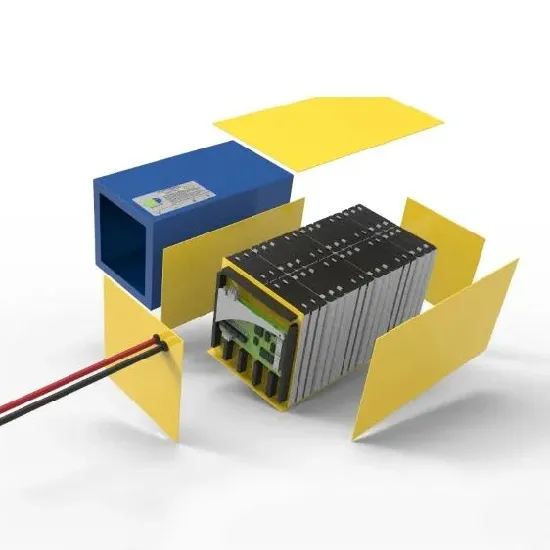

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.