Photovoltaic Technology: The Case for Thin-Film

The advantages and limitations of photovoltaic solar modules for energy generation are reviewed with their operation principles and physical

Get a quote

Thin Film Photovoltaics

In addition to the fact that thin-film modules must be priced at about $75/m2, they must produce electricity at an efficiency implying an ac system efficiency of 10%, and they must lose less

Get a quote

Thin Film Photovoltaics

Thin film technology has the answers and potential to eliminate many existing bottlenecks of c-Si photovoltaic (PV) programs experienced at different levels from module

Get a quote

Thin-film solar cell

Thin-film solar cells are a type of solar cell made by depositing one or more thin layers (thin films or TFs) of photovoltaic material onto a substrate, such as glass, plastic or metal.

Get a quote

CdTe photovoltaic technology: An overview of waste generation

CdTe panel is a leader among thin-film technologies for solar panels and, according to some studies, promises the lowest production cost compared with other PV technology

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros & Cons

The most commonly used ones for thin-film solar technology are cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous silicon (a-Si), and gallium

Get a quote

Advanced Thin-Film Solar Panel Manufacturing: How Modern

As manufacturing processes become more refined and standardized, thin-film technology is positioned to play a crucial role in the global transition to renewable energy,

Get a quote

ZSW: Thin-film solar cells and modules

In 2014, the total global production of photovoltaic modules with a-Si, CdTe and CIGS absorbers amounted to 3,144 MW, which comprised 8% of the total

Get a quote

Thin-Film Solar Cell Manufacturing | Department of Energy

In this b-roll, thin-film photovoltaic cells are manufactured and deployed in Arizona. Steps shown in the manufacturing process include the screen printing of conductive material

Get a quote

Advancing U.S. Thin-Film Solar Photovoltaics Funding

The Advancing U.S. Thin-Film Solar Photovoltaics funding program awards $44 million for research, development, and demonstration projects on two major

Get a quote

What is thin-film PV? | PVthin

A thin-film solar cell is a solar cell that is made by depositing one or more ultra-thin layers (much thinner than a human hair), or thin-film of photovoltaic

Get a quote

Challenges and Perspectives of Thin-Film Photovoltaics

The present paper gives an overview about the most advanced thin-film solar cell technologies, highlights recent developments and, finally, discusses challenges for research and

Get a quote

Thin-Film Solar Technology

PowerFilm''s flagship thin-film material is based on Amorphous Silicon (a-Si) PV technology. This technology is highly flexible, durable, lightweight, and has

Get a quote

Recent Advancements in Thin-Film Solar Modules

Thin-film solar modules transform the renewable energy landscape with their lightweight design, flexibility, and cost-effective production. Unlike traditional silicon-based

Get a quote

Everything You Need To Know About Thin-Film Solar Panels

What is a thin film solar panel? Thin-film solar panels are a type of photovoltaic solar panels that are made up of one or more thin layers of PV materials. These thin, light-absorbing layers can

Get a quote

The next level for thin-film solar modules

Calyxo GmbH has specialized in the production of such thin-film solar modules. Such modules are made up of several layers of photosensitive layers (films), which are only a few micrometres

Get a quote

Thin-film modules: Benefits and considerations in utility-scale

What are thin-film solar photovoltaic (PV) modules and what are the main considerations when using them in a utility-scale solar plant?

Get a quote

Thin-film solar cell

OverviewEnvironmental and health impactHistoryTheory of operationMaterialsEfficienciesProduction, cost and marketDurability and lifetime

In order to meet international renewable energy goals, the worldwide solar capacity must increase significantly. For example, to keep up with the International Energy Agency''s goal of 4674 GW of solar capacity installed globally by 2050, significant expansion is required from the 1185 GW installed globally as of 2022. As thin-film solar cells have become more efficient and commercially viable, it has become clear that they will play an important role in meeting these goals. As such

Get a quote

The next level for thin-film solar modules

Calyxo GmbH has specialized in the production of such thin-film solar modules. Such modules are made up of several layers of photosensitive layers (films),

Get a quote

ZSW: Thin-film solar cells and modules

In 2014, the total global production of photovoltaic modules with a-Si, CdTe and CIGS absorbers amounted to 3,144 MW, which comprised 8% of the total annual production of solar modules.

Get a quote

Solar Photovoltaic Cell Basics

A thin-film solar cell is made by depositing one or more thin layers of PV material on a supporting material such as glass, plastic, or metal. There are two main

Get a quote

Thin-film modules: Benefits and considerations in

What are thin-film solar photovoltaic (PV) modules and what are the main considerations when using them in a utility-scale solar plant?

Get a quote

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Get a quote

large-Scale Photovoltaic energy Production from Web-based,

IntroduCtIon Thin-film PV modules that convert sunlight directly into electricity are viewed as important options for large-scale electricity production. If the ~35% exponential growth in

Get a quote

Challenges and Perspectives of Thin-Film Photovoltaics

Driven by new developments of large area coating for architectural glazing or microelectronic products like flat panel displays, thin film technology reaches the reliability and performance

Get a quote

Photovoltaics: Materials, Cells and Modules

Perovskite-based Thin-Film Photovoltaic Module Our laboratory infrastructure enables the scalable production of perovskite solar cells and their monolithic

Get a quote

Advanced Thin-Film Solar Panel Manufacturing: How

As manufacturing processes become more refined and standardized, thin-film technology is positioned to play a crucial role in the

Get a quote

Advanced Thin-Film Solar Panel Manufacturing: How

Thin-film solar panels represent a revolutionary advancement in solar PV technology, offering unprecedented flexibility and cost-effectiveness

Get a quote

Guess what you want to know

-

Global thin-film photovoltaic module production capacity

Global thin-film photovoltaic module production capacity

-

Thin-film photovoltaic module subsidies

Thin-film photovoltaic module subsidies

-

Thin-film photovoltaic module parameters

Thin-film photovoltaic module parameters

-

Rooftop thin-film photovoltaic module price

Rooftop thin-film photovoltaic module price

-

Solar photovoltaic module production in Luxembourg

Solar photovoltaic module production in Luxembourg

-

Thin-film photovoltaic module warranty

Thin-film photovoltaic module warranty

-

Lebanon rooftop photovoltaic module prices

Lebanon rooftop photovoltaic module prices

-

Good photovoltaic module prices in China

Good photovoltaic module prices in China

-

Photovoltaic inverter DCAC module

Photovoltaic inverter DCAC module

-

Photovoltaic power generation module prices in Morocco

Photovoltaic power generation module prices in Morocco

Industrial & Commercial Energy Storage Market Growth

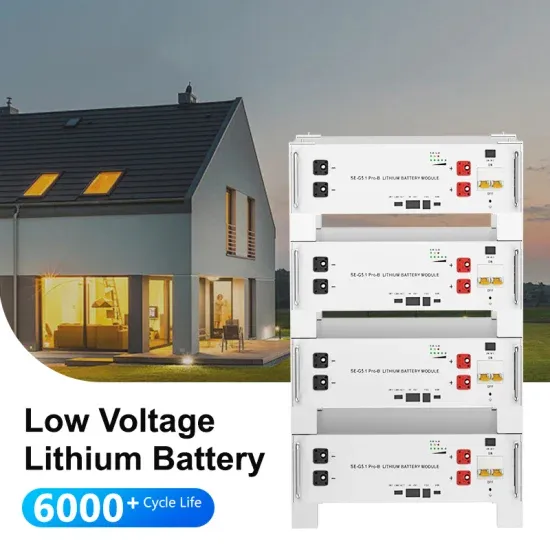

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.