Flexible and transparent thin-film light-scattering photovoltaics

Abstract Flexible and transparent thin-film silicon solar cells were fabricated and optimized for building-integrated photovoltaics and bifacial operation.

Get a quote

CdTe-Based Thin Film Solar Cells: Past, Present and

CdTe is a very robust and chemically stable material and for this reason its related solar cell thin film photovoltaic technology is now the only

Get a quote

Thin-Film Solar Panels: An In-Depth Guide | Types, Pros & Cons

Thin-film solar cells (TFSC) are manufactured using a single or multiple layers of PV elements over a surface comprised of a variety of glass, plastic, or metal.

Get a quote

Everything You Need To Know About Thin-Film Solar Panels

What is a thin film solar panel? Thin-film solar panels are a type of photovoltaic solar panels that are made up of one or more thin layers of PV materials. These thin, light-absorbing layers can

Get a quote

How Thin-film Solar Cells Work

Thin-film solar cell manufacturers begin building their solar cells by depositing several layers of a light-absorbing material, a semiconductor onto a substrate -- coated glass,

Get a quote

Typical structure of a thin film solar cell.

Typical structure of a thin film solar cell. Polycrystalline thin film solar cells made with absorber materials such as CdTe, CIGS, CZTS and metalorganic halides (perovskites) are...

Get a quote

Thin-film modules: Benefits and considerations in utility-scale

Differences in the structure of thin-film modules compared with silicon modules mean that you need to make slightly different calculations to get the highest efficiency from

Get a quote

Thin-film solar cell

OverviewEfficienciesHistoryTheory of operationMaterialsProduction, cost and marketDurability and lifetimeEnvironmental and health impact

Despite initially lower efficiencies at the time of their introduction, many thin-film technologies have efficiencies comparable to conventional single-junction non-concentrator crystalline silicon solar cells which have a 26.1% maximum efficiency as of 2023. In fact, both GaAs thin-film and GaAs single-crystal cells have larger maximum efficiencies of 29.1% and 27.4% respectively. The maxi

Get a quote

How Thin-film Solar Cells Work

Because structure and function are so closely linked with solar cells, let''s take a moment to review how they work. The basic science behind thin-film solar

Get a quote

Cadmium telluride (CdTe) thin film solar cells

Semiconductors are the basic photovoltaic materials used in inorganic solar cells. Recently, research activities have shifted progressively toward thin film solar cells utilizing

Get a quote

Discover the Thin-Film Solar Panels | A Complete Guide

Thin-film solar panels are a photovoltaic technology which utilizes layers of very thin photovoltaic conductive films on a supporting material. Thin-film solar panels use

Get a quote

ZSW: Thin-film solar cells and modules

This is real thin-film technology (the total thickness of all the layers is just a few thousandths of a millimetre on substrates made of window glass or metal or plastic films), and is mostly based

Get a quote

Thin-Film Solar Panels

You can easily recognize this solar cell type by their thin appearance -they are named "Thin-Film" for a reason-. These panels are very thin that each layer is only 1 micron

Get a quote

Thin-Film Modules

They can be produced either in single-junction or multi-junction configurations. While the single-junction configurations involve only one cell and only cover one part of the solar spectrum, the

Get a quote

Lightweight and flexible Cu(In,Ga)Se2 solar minimodules: toward

Lightweight and flexible photovoltaic solar cells and modules are promising technologies that may result in the wide usage of light-to-electricity energy conversion devices.

Get a quote

Thin Film Solar Panels

Introduction As the name suggests, thin film PV employs a very thin layer of semiconductor – usually just a couple of microns thick – in place of a traditional silicon wafer. Simpler to

Get a quote

PVI17_Publishers_Foreword dd

ABSTRACT Thin-film solar cells (TFSCs) still hold unlocked potential for achieving both high efficiency and low manufacturing costs. The formation of integrated interconnects is a useful

Get a quote

How Thin-film Solar Cells Work

Thin-film solar cell manufacturers begin building their solar cells by depositing several layers of a light-absorbing material, a semiconductor onto a substrate -- coated glass, metal or plastic.

Get a quote

Thin-film modules: Benefits and considerations in

Differences in the structure of thin-film modules compared with silicon modules mean that you need to make slightly different calculations to

Get a quote

Inventions, innovations, and new technologies: Flexible and

This survey examines new and emerging applications and technology advancements that hold potential for effective use and market expansion of thin-film solar

Get a quote

Thin-film solar cell

Thin-film solar cells are a type of solar cell made by depositing one or more thin layers (thin films or TFs) of photovoltaic material onto a substrate, such as glass, plastic or metal.

Get a quote

What are thin-film solar cells? description, and types

These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate, such as glass, plastic, or metal. The thickness of the film

Get a quote

Typical structure of a thin film solar cell.

Typical structure of a thin film solar cell. Polycrystalline thin film solar cells made with absorber materials such as CdTe, CIGS, CZTS and metalorganic halides

Get a quote

ZSW: Thin-film solar cells and modules

This is real thin-film technology (the total thickness of all the layers is just a few thousandths of a millimetre on substrates made of window glass or metal or

Get a quote

Everything You Need To Know About Thin-Film Solar

What is a thin film solar panel? Thin-film solar panels are a type of photovoltaic solar panels that are made up of one or more thin layers of PV materials.

Get a quote

thin film solar cell

Polycrystalline thin-film cells have a heterojunction structure, in which the top layer is made of a different semiconductor material than the bottom semiconductor layer. The top layer, usually n

Get a quote

Thin-Film Solar Cells: Definition, Types & Costs

The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition

Get a quote

Thin Film vs. Crystalline Silicon PV Modules

There is a competitive price advantage of Thin Film modules over Crystalline Silicon PV modules. Despite the fact that the global thin film module

Get a quote

Guess what you want to know

-

Rooftop thin-film photovoltaic module price

Rooftop thin-film photovoltaic module price

-

Thin-film photovoltaic module production

Thin-film photovoltaic module production

-

Thin-film photovoltaic module subsidies

Thin-film photovoltaic module subsidies

-

Thin-film photovoltaic module parameters

Thin-film photovoltaic module parameters

-

How much does a monocrystalline silicon photovoltaic module cost

How much does a monocrystalline silicon photovoltaic module cost

-

Photovoltaic cell module equipment

Photovoltaic cell module equipment

-

Guatemala Photovoltaic Cell Module Project

Guatemala Photovoltaic Cell Module Project

-

Perc photovoltaic module design

Perc photovoltaic module design

-

EU standard photovoltaic module panels

EU standard photovoltaic module panels

-

Main structure of solar photovoltaic panels

Main structure of solar photovoltaic panels

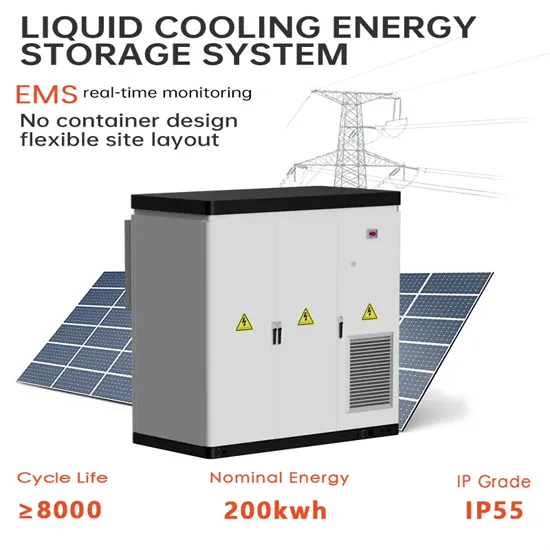

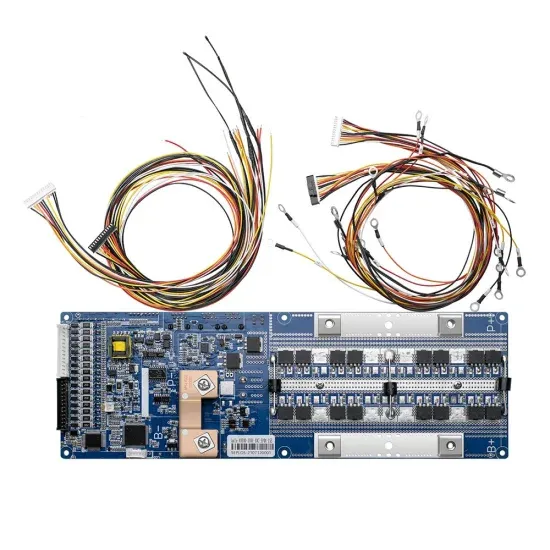

Industrial & Commercial Energy Storage Market Growth

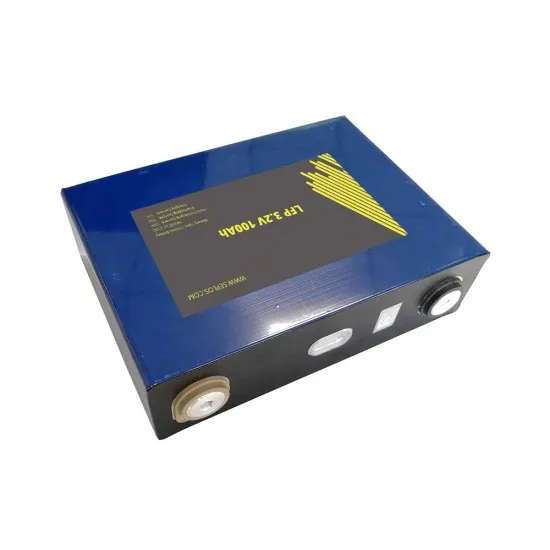

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.