China''s REPT Battero to build battery factory in Indonesia

China''s REPT Battero has revealed plans to build a lithium-ion battery plant in Indonesia, targeting 8 GWh of annual production capacity in the first phase.

Get a quote

Financing for Indonesia''s first EV battery plant marks

The nickel materials will be used in Tesla''s lithium batteries. The move would be in line with Indonesia''s desire to encourage more domestic

Get a quote

Indonesia bets on Southeast Asia''s first battery plant to become

R ows of robotic arms move with precision to assemble nickel-based battery cells on the production line at Indonesia''s inaugural electric vehicle battery plant, the first in

Get a quote

CATL plans US$5 billion Indonesia battery plant, hot

Contemporary Amperex Technology (CATL), China''s largest producer of automobile battery packs, plans to build a US$5 billion plant in

Get a quote

Indonesia-China lithium battery plant to be operational

JAKARTA: A lithium-ion battery plant by an Indonesian company and China''s CATL is expected to be in operation by the end of 2026 with an

Get a quote

CATL begins construction of EV battery plant in Indonesia

The battery plant is part of a broader integrated EV battery manufacturing and supply chain project valued at US$ 6 billion in total, originally signed in 2022.

Get a quote

Indonesia, CATL Consortium begin construction on

JAKARTA: A lithium-ion battery plant by an Indonesian company and China''s CATL is expected to be in operation by the end of 2026 with initial capacity of

Get a quote

Seizing Indonesia''s Position in the Global Supply

Indonesia, in fact, establishesseveral project portfolios for the development of EV battery ecosystems and integrated battery energy storage

Get a quote

Hyundai & LG Open Indonesia''s First EV Battery Plant

Indonesia, renowned for its vast nickel reserves, has inaugurated Southeast Asia''s first EV battery manufacturing plant in Karawang, West Java. HLI Green Power, a joint venture

Get a quote

Top 3 Lithium Battery Companies in Indonesia in 2024

As Southeast Asia''s largest economy, Indonesia has strategically positioned itself as a critical player in the global battery supply chain, with several key cities developing into hubs for lithium

Get a quote

Indonesia to lead SEA battery manufacturing by 2030

Indonesia is on track to become the largest lithium-ion battery and component manufacturing hub in Southeast Asia. This is thanks to its abundant raw material resources,

Get a quote

China''s REPT BATTERO plans 8-GWh battery factory

Chinese lithium-ion battery manufacturer REPT BATTERO Energy Co Ltd (HKG:666) has decided to invest in the construction of a battery factory

Get a quote

Indonesia, CATL Consortium begin construction on US$6bil EV battery

JAKARTA: A lithium-ion battery plant by an Indonesian company and China''s CATL is expected to be in operation by the end of 2026 with initial capacity of 6.9 gigawatt hours, an Indonesian

Get a quote

Indonesia''s first EV battery cell factory to begin

Indonesia''s first electric vehicle battery cell factory will begin operations in April, with most of its output exported to South Korea and India.

Get a quote

China''s REPT Battero to build battery factory in

China''s REPT Battero has revealed plans to build a lithium-ion battery plant in Indonesia, targeting 8 GWh of annual production capacity in

Get a quote

Rept Battero to develop 8GWh Indonesia BESS cell gigafactory

Chinese battery manufacturer Rept Battero has announced plans to develop an 8GWh gigafactory in Indonesia specialising in lithium-ion cells for battery energy storage

Get a quote

Hyundai & LG Open Indonesia''s First EV Battery Plant

Indonesia, renowned for its vast nickel reserves, has inaugurated Southeast Asia''s first EV battery manufacturing plant in Karawang, West Java.

Get a quote

China''s REPT Battero to build battery manufacturing

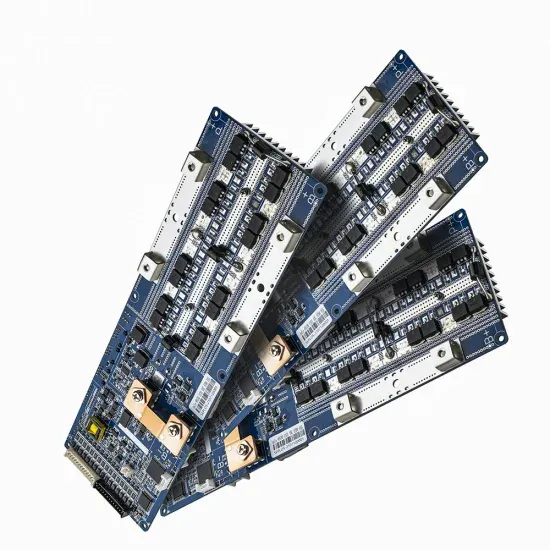

The new factory will focus on manufacturing lithium-ion batteries, modules, and packs, catering to both electric vehicles and energy storage

Get a quote

Indonesia to lead SEA battery manufacturing by 2030

Indonesia is on track to become the largest lithium-ion battery and component manufacturing hub in Southeast Asia. This is thanks to its

Get a quote

China''s REPT Battero to build battery manufacturing plant in Indonesia

The new factory will focus on manufacturing lithium-ion batteries, modules, and packs, catering to both electric vehicles and energy storage systems. The first phase of the

Get a quote

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack assembling with

Get a quote

Indonesia to Scale Up Battery Manufacturing for Electric Vehicles

In December 2020, Chinese battery cell manufacturer CATL announced plans to invest USD 5 billion in a lithium battery plant in Indonesia. The plant will commence production in 2024.

Get a quote

Indonesia Bets on SE Asia''s First Battery Plant to Become EV Hub

By Marchio Gorbiano Rows of robotic arms move with precision to assemble nickel-based battery cells on the production line at Indonesia''s inaugural electric vehicle

Get a quote

China''s REPT BATTERO plans 8-GWh battery factory in Indonesia

Chinese lithium-ion battery manufacturer REPT BATTERO Energy Co Ltd (HKG:666) has decided to invest in the construction of a battery factory in Indonesia with an

Get a quote

Indonesia-China lithium battery plant to be operational by end-2026

JAKARTA: A lithium-ion battery plant by an Indonesian company and China''s CATL is expected to be in operation by the end of 2026 with an initial capacity of 6.9 gigawatt

Get a quote

CATL Breaks Ground on Major Indonesian Battery Plant

Contemporary Amperex Technology Co. Limited (CATL), the world''s largest battery manufacturer, has officially broken ground on a massive battery cell factory in

Get a quote

Battery Cell Manufacturing Process

Battery Cell Manufacturing Process In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process.

Get a quote

CATL Breaks Ground on Major Indonesian Battery Plant

Contemporary Amperex Technology Co. Limited (CATL), the world''s largest battery manufacturer, has officially broken ground on a massive

Get a quote

EV Battery Indonesia: The Prospects and Challenges

Indonesia''s large deposits of raw materials are most likely to further fuel the growth of the battery market in Indonesia. The Indonesian battery

Get a quote

Top 3 Lithium Battery Companies in Indonesia in 2024

As Southeast Asia''s largest economy, Indonesia has strategically positioned itself as a critical player in the global battery supply chain, with several key cities

Get a quote

Guess what you want to know

-

Ethiopia lithium battery station cabinet production plant

Ethiopia lithium battery station cabinet production plant

-

12Ah lithium battery pack production

12Ah lithium battery pack production

-

Moldova lithium battery production plant

Moldova lithium battery production plant

-

60v 32ah lithium battery pack production

60v 32ah lithium battery pack production

-

12v 25ah lithium battery pack production

12v 25ah lithium battery pack production

-

Is the secondary lithium battery pack durable

Is the secondary lithium battery pack durable

-

100 kWh lithium battery pack

100 kWh lithium battery pack

-

Oman 48V lithium battery pack

Oman 48V lithium battery pack

-

Replace the AA battery pack with lithium batteries

Replace the AA battery pack with lithium batteries

-

Croatia custom lithium battery pack

Croatia custom lithium battery pack

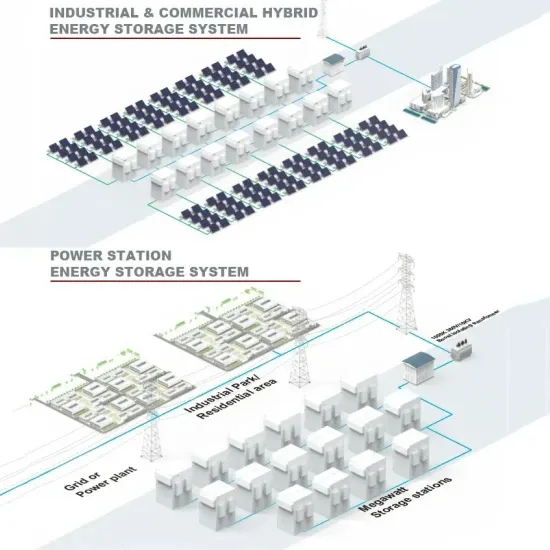

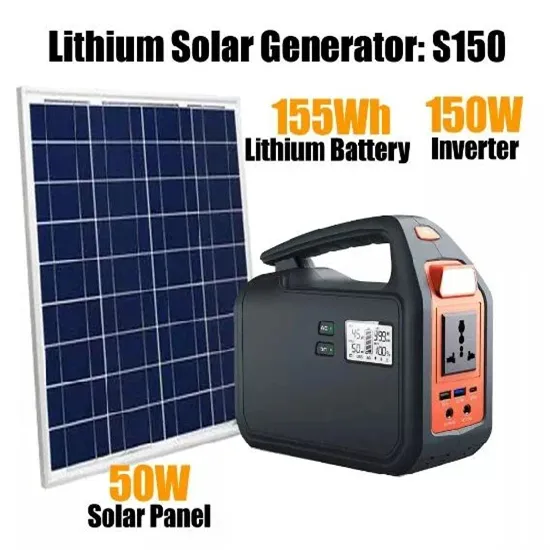

Industrial & Commercial Energy Storage Market Growth

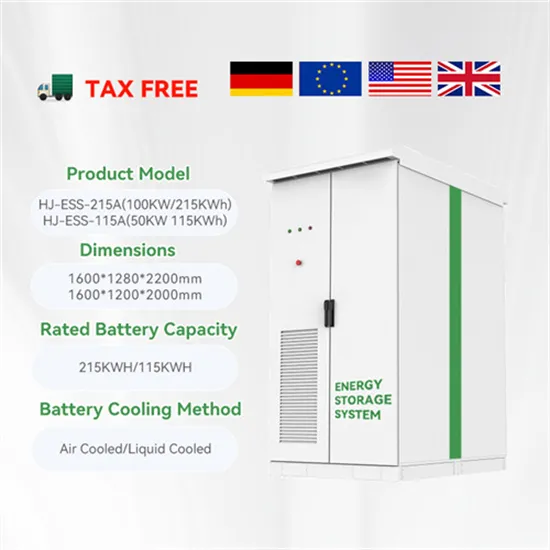

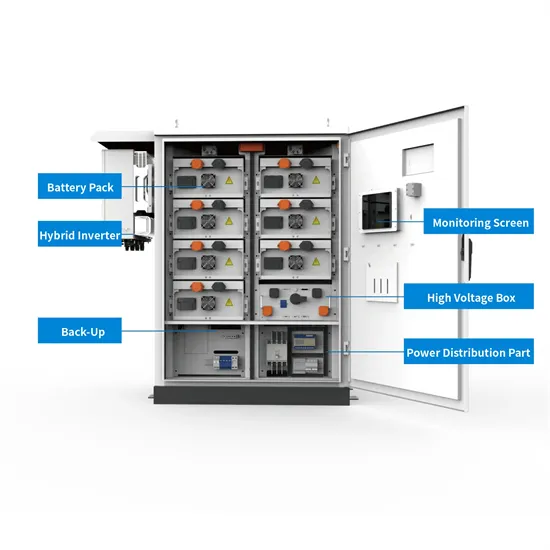

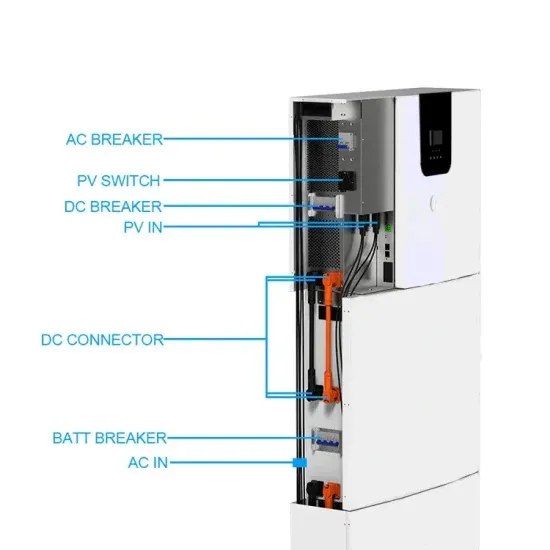

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.