M12 12V Lithium-Ion High Output 2.5Ah and 5Ah

The M12 12V Lithium-Ion CP High Output 2.5 Ah Battery Pack has a voltage of 12V and an amp-hour rating of 2.5 Ah. To calculate the watt-hours (Wh), you

Get a quote

Batteries | Power Tools | Service. Trust. Results.®

Learn how Batteries can make your job easier and save you time. Professional mechanics and auto techs #1 trusted source for automotive repair tools.

Get a quote

Amazon : Lipo Battery 12v

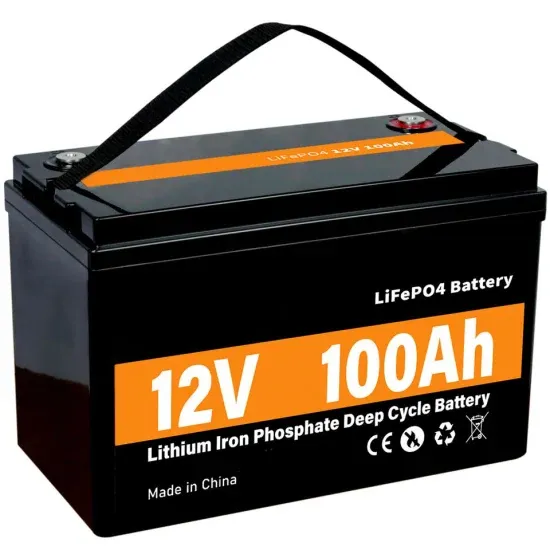

2 Pack 12V 10Ah Lithium Ion LiFePO4 Deep Cycle Battery, 2000+ Cycles Rechargeable Battery for Solar/Wind Power, Scooters, Lighting, Power Wheels, Fish Finder Built-in 10A BMS

Get a quote

12 Volt Lithium Ion Batteries in 12 Volt Batteries

Shop for 12 Volt Lithium Ion Batteries in 12 Volt Batteries. Buy products such as D0NGHOT 12V 100Ah Lithium Iron Phosphate Battery for Trolling Motor,RV,Marine,Off Grid,Solar at Walmart

Get a quote

Topping-Out ceremony for MAN''s new battery production facility

Currently, the plant produces battery packs in small-scale operations ahead of the completion of the new production line. The facility will feature over 50 manual and automated

Get a quote

ECI Power 12V 5Ah Lithium LiFePO4 Deep Cycle

Complete Protection: The lithium battery''s unique built-in Battery Management System (BMS) protects it from overcharge, deep discharge, overloading,

Get a quote

MAN Truck & Bus Advances Battery Production with New Facility

The Nuremberg facility will assemble battery packs from lithium-ion modules, which contain nickel, manganese, and cobalt. The packs will power MAN''s eTruck, urban

Get a quote

12v 25Ah LiFePO4 battery

We use the latest LiFePo4 lithium battery technologies to make the 12V rechargeable batteries just ensure that you can get the highest quality and less or even no customer returns, we work

Get a quote

12V 5Ah Li-Ion Lithium Ion Battery Pack for E-Bike,

Maximum Capacity – 5 AH or 5000 mah Battery voltage- 12v Very Small in size and weight compared to Ni-Cd, Ni-MH, Li-ion and Lead Acid Batteries Long

Get a quote

Aegis Battery

A leading Lithium Ion and LiFePO4 Battery developer and manufacturer. Aegis Battery provides quality and affordable Lithium Ion Battery solutions for consumers and OEM business needs.

Get a quote

Dakota Lithium DL+ 12 Volt, 25 Ah, 300CCA LiFePO4

The DL 25Ah battery is built with Dakota Lithium''s legendary LiFePO4 cells. 2,000+ recharge cycles (roughly 5 year lifespan at daily use) vs. 500 for lead

Get a quote

Topping-Out ceremony for MAN''s new battery

Currently, the plant produces battery packs in small-scale operations ahead of the completion of the new production line. The facility will

Get a quote

Dakota Lithium 12v 25Ah Battery

New lead acid batteries for it have lasted about a year and cost around $100 so the Dakota Lithium version which has an amazing 11 year warranty, and costs 2.5x the lead

Get a quote

Amazon.ae: Lithium Battery 12v

ERYY LiFePO4 Battery 12V 25Ah (30Ah) 384WH, Built-in 30A BMS & LCD Display, 5000+ Deep Cycles Rechargeable Lithium Iron Phosphate Battery Perfect for RVs, Trolling Motor, Camping

Get a quote

Battery 12V

Battery 12V-25Ah – Lithium-ion (18650 – INR) Brand: Den Bloom Nominal voltage : 12.3V 4500 cycles at 80% DoD @ 2C 3000 cycles at 100% DoD @ 2C 98% energy efficient 100%

Get a quote

MAN celebrates completion of works at battery manufacturing

MAN Truck & Bus celebreates the completion of the new building for the large-scale production of batteries for fully electric trucks and buses at its Nuremberg site

Get a quote

12V 25ah LiFePO4 Lithium Battery Pack with 2000 Cycles

12V 25ah LiFePO4 Lithium Battery Pack with 2000 Cycles offered by China manufacturer DELONG ENERGY. Buy 12V 25ah LiFePO4 Lithium Battery Pack with 2000 Cycles directly

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

MAN celebrates completion of works at battery

MAN Truck & Bus celebreates the completion of the new building for the large-scale production of batteries for fully electric trucks and buses at

Get a quote

Custom Rechargeable 18650, Li-ion, LiPo & LiFePO4 Battery

As an ISO 9001:2015 certified lithium battery manufacturer, we specialize in custom battery pack design and production. Our advanced facility produces high-performance

Get a quote

4 FAQs about [12v 25ah lithium battery pack production]

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

How can lithium-ion cell technology improve a custom pack design?

Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities. Concurrent electrical and mechanical engineering is needed to optimize the custom pack design within constraints.

Guess what you want to know

-

60v 32ah lithium battery pack production

60v 32ah lithium battery pack production

-

Minimum 12v 2a lithium battery pack

Minimum 12v 2a lithium battery pack

-

Timor-Leste pack lithium battery production

Timor-Leste pack lithium battery production

-

12v 72Ah lithium battery pack

12v 72Ah lithium battery pack

-

Manufacturing 12v lithium battery pack

Manufacturing 12v lithium battery pack

-

Huijue Iraq lithium battery pack 12v

Huijue Iraq lithium battery pack 12v

-

12v lithium battery pack can

12v lithium battery pack can

-

Russian 12v lithium battery pack factory

Russian 12v lithium battery pack factory

-

Power amplifier 12v lithium battery pack

Power amplifier 12v lithium battery pack

-

Malawi lithium battery 12v battery pack

Malawi lithium battery 12v battery pack

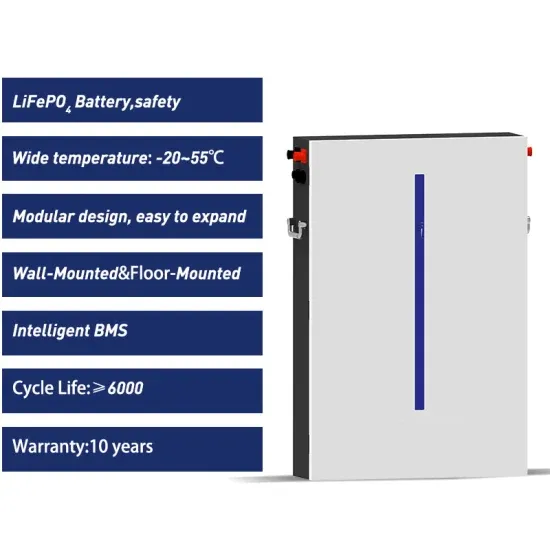

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.