How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get a quote

Inside the Battle Born Lithium Battery Manufacturing Facility

American Lithium Battery Manufacturing At our Reno facility, we oversee every stage of the LiFePO4 battery production process. From cell selection to final quality checks,

Get a quote

lifepo4 battery manufacturer & Commercial Battery

QH is a high-technical Lifepo4 Battery Manufacturer specializing in research, production, and wholesale lifepo4 home battery and multi-scenario

Get a quote

Constructing a 12V Lithium Ion Battery Pack: A Comprehensive

As a leading manufacturer of lithium polymer batteries and lithium-ion batteries, LiPol guides constructing your 12V lithium-ion battery pack. Steps to Create a 12V Lithium-ion Battery

Get a quote

Batteries

Optimized For 12 Volt Lithium Batteries - 10 amp charger for rapid charging of larger batteries Fully automatic four-stage charging with MCU control. Clear battery status display with four

Get a quote

Custom Lithium Battery Pack Manufacturers

Experience the best energy solutions with lithium battery suppliers in the USA, trusted battery pack manufacturers, and high-performance electric battery

Get a quote

Lithium Battery Manufacturers in India

Find here Lithium Battery, Lithium Battery 12V manufacturers & OEM manufacturers in India. Get Contact details & address of companies manufacturing and supplying Lithium Battery, Lithium

Get a quote

How I made a 12V Lithium-Ion battery at home for just

If it looks like a lead-acid battery then it must be a lead-acid battery, right ? Not necessarily Here is how my son made a 12v Lithium-ion

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

Battery Module & Pack Manufacturing: Step-by-Step

Manufacturers are embedding thermal interface materials, fire protection systems, and innovative pack geometries to manage heat dissipation and prevent thermal runaway — a

Get a quote

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get a quote

Lithium Battery Packs | BigBattery | Your Source for

"Big Battery made converting our 48v lead acid EZGO cart to lithium a breeze. Our cart is lighter, faster and the range went up dramatically using just a single

Get a quote

Lithium Ion Battery Packs Manufacturers | Battrixx

Battrixx produces green energy systems and solutions with advanced lithium-ion battery packs to power the growth of India''s transition to green energy storage

Get a quote

"Build a 12V 15A Powerful LiFePO4 Battery | DIY Step-by-Step

Build your own powerful 12V system with this guide! 🔋 Specs: Voltage: 12.8V (nominal), 14.6V (max) Continuous Current Output: 15 Amps Cell Configuration: 4S LiFePO₄ Capacity: Adjustable (20Ah

Get a quote

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Building lithium-ion battery packs requires systematic engineering across multiple disciplines, from cell selection to safety compliance. Here are the essential insights every

Get a quote

How to Make a 12V Lithium-Ion Battery Pack: 4 Steps DIY Guide

Whatever your reason: building your own 12V lithium-ion battery pack isn''t just possible—it''s empowering. I''ve seen beginners crank out reliable packs for under $100 using

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

USA Made Batteries | Brand & Manufacturers List

We have compiled a list of U.S. battery manufacturers & brands, that includes 15 companies who produce some of the best aaa, aa, c, d & 9v alkaline batteries;

Get a quote

Expert Battery Pack Engineering & Manufacturing for

High-Performance Lithium-Ion Battery Packs, Custom Battery Packs, Battery Chargers and Battery Pack Design Lithium-Ion, Lithium Iron Phosphate, LiPo

Get a quote

How to Make a 12V Lithium-Ion Battery Pack: 4 Steps

Whatever your reason: building your own 12V lithium-ion battery pack isn''t just possible—it''s empowering. I''ve seen beginners crank out

Get a quote

6 FAQs about [Manufacturing 12v lithium battery pack]

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

What is the cell assembly process in lithium batteries?

The cell assembly process in lithium batteries involves arranging and connecting individual cells to form a complete battery pack. This includes cell sorting, mounting, resistance and laser welding, and integrating the Battery Management System (BMS).

Guess what you want to know

-

Pack lithium battery manufacturing

Pack lithium battery manufacturing

-

Power amplifier 12v lithium battery pack

Power amplifier 12v lithium battery pack

-

Huijue Iraq lithium battery pack 12v

Huijue Iraq lithium battery pack 12v

-

12v 110a lithium battery pack

12v 110a lithium battery pack

-

12v lithium battery pack as power source

12v lithium battery pack as power source

-

12v 80ah lithium battery pack

12v 80ah lithium battery pack

-

12v lithium battery pack can

12v lithium battery pack can

-

Minimum 12v 2a lithium battery pack

Minimum 12v 2a lithium battery pack

-

12v lithium battery pack high power

12v lithium battery pack high power

-

12V 2A lithium battery pack

12V 2A lithium battery pack

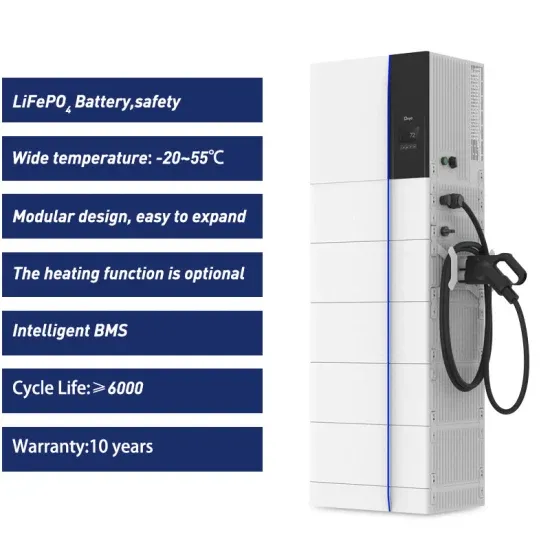

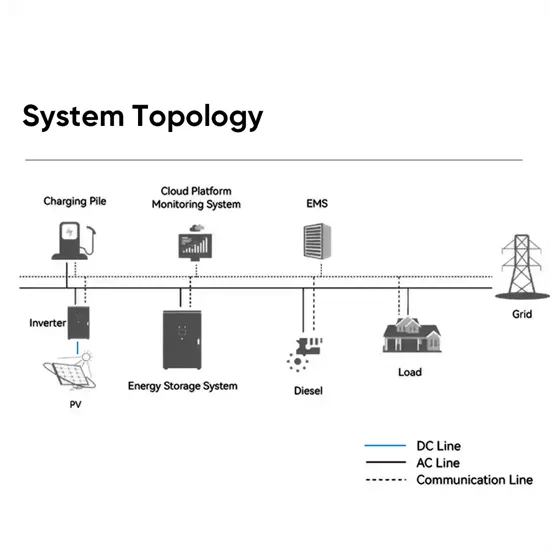

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

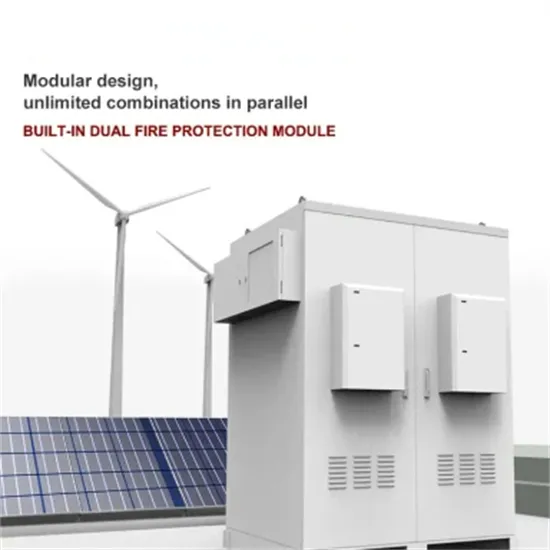

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.