How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get a quote

How EV Batteries Are Made: The Cell Manufacturing Process

Learn about the key steps in the lithin-ion batter manufacturing process, from raw material preparation to module and pack assembly and vehicle integration.

Get a quote

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will

Get a quote

Battery Module & Pack Manufacturing: Step-by-Step

Global Trends: Investing in Turnkey Equipment for Battery Pack Manufacturing. As the industry evolves, battery manufacturers are rapidly adopting the following trends: 1.

Get a quote

13 Largest Battery Manufacturers In The World [2025]

Did you know? China is the undisputed leader in battery manufacturing, dominating the global production of essential battery materials

Get a quote

Battery Cell Manufacturing Process

In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery cell manufacturing process. This will allow you to understand some of the

Get a quote

Automotive battery pack manufacturing – a review of battery to

Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Get a quote

Current and future lithium-ion battery manufacturing

Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share of LIBs h

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

How are Lithium-ion Battery Packs Manufactured?

Discover the step-by-step process of lithium-ion battery packs manufacturing and learn how these essential components are made. Read the full guide now!

Get a quote

Lithium-Ion Battery (LiB) Manufacturing Landscape in India

Existing battery pack manufacturers like Amara Raja and Exide, which are also the top lead acid battery manufacturers in India, have already announced their plans to start lithium-ion cell

Get a quote

Current and future lithium-ion battery manufacturing

Lithium-ion batteries (LIBs) have been widely used in portable electronics, electric vehicles, and grid storage due to their high energy density, high power density, and long cycle life. Since

Get a quote

Battery Module & Pack Manufacturing: Step-by-Step

Global Trends: Investing in Turnkey Equipment for Battery Pack Manufacturing. As the industry evolves, battery manufacturers are rapidly

Get a quote

What Is the Process of Lithium-Ion Battery Pack Assembly

As a vital element in the lithium ion battery manufacture process, the pack plays a pivotal role in the production, design, and application of power battery systems.

Get a quote

Custom Rechargeable 18650, Li-ion, LiPo & LiFePO4

Advanced lithium battery manufacturing with 2-year warranty. Specializing in LiFePO4, Li-ion, and LiPo battery packs for industrial,

Get a quote

The EV Battery Manufacturing Process: Step by Step

The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Get a quote

Turnkey Lithium Ion Battery (LIB) Manufacturing

Providing turnkey processes and equipment related to the manufacturing of all lithium-ion batteries (LIB). Turnkey solutions for Li-Ion Batteries (LIB)

Get a quote

(Infographics #3) Battery Making at a Glance

(Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode manufacturing, cell assembly,

Get a quote

Lithium Battery Module PACK Manufacturing Guide

This article outlines the key points of the lithium battery module PACK manufacturing process, emphasizing the critical stages contributing to the final product''s

Get a quote

Advanced Lithium Battery Manufacturing Capabilities

At Lithium Battery Company, we specialize in advanced battery pack assembly for OEMs and energy innovators. Our U.S.-based facility delivers scalable, automation-first solutions across

Get a quote

Lithium Battery Manufacturing Process

A Lithium-ion battery is an advanced battery technology which is getting very popular around the world these days. From power backup at home to automobiles,

Get a quote

What Is the Process of Lithium-Ion Battery Pack

As a vital element in the lithium ion battery manufacture process, the pack plays a pivotal role in the production, design, and application of

Get a quote

Guess what you want to know

-

Manufacturing 12v lithium battery pack

Manufacturing 12v lithium battery pack

-

Tajikistan professional lithium battery pack factory price

Tajikistan professional lithium battery pack factory price

-

Lesotho rechargeable pack lithium battery

Lesotho rechargeable pack lithium battery

-

Is Niue s lithium battery pack safe

Is Niue s lithium battery pack safe

-

Which lithium battery pack is better in Kuwait

Which lithium battery pack is better in Kuwait

-

Lithium battery pack outer box container base station

Lithium battery pack outer box container base station

-

How long does it take to charge a lithium battery pack

How long does it take to charge a lithium battery pack

-

48v 60ah lithium battery pack weight

48v 60ah lithium battery pack weight

-

Removable lithium battery pack

Removable lithium battery pack

-

2kWh lithium iron phosphate battery pack

2kWh lithium iron phosphate battery pack

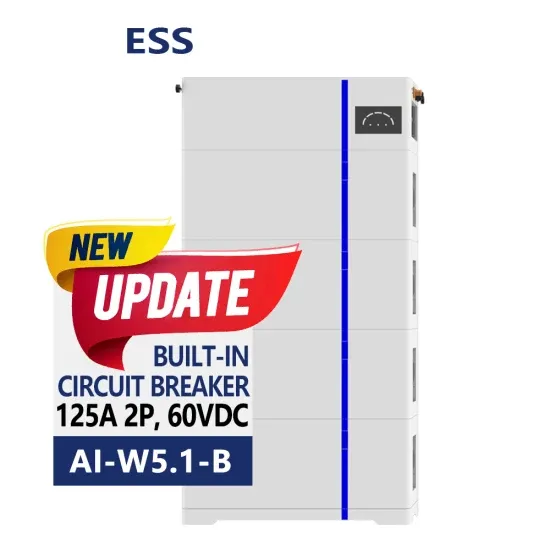

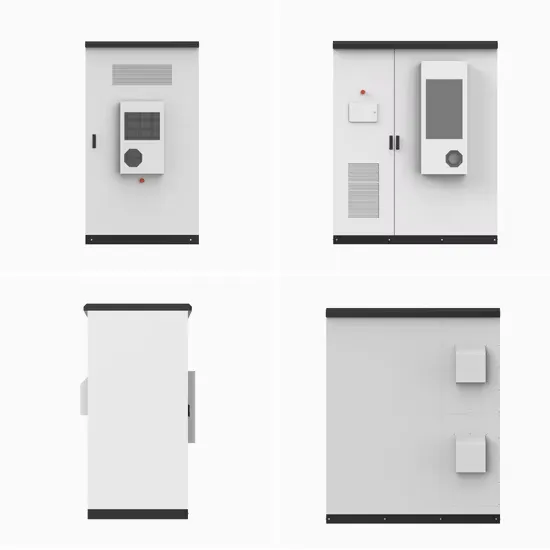

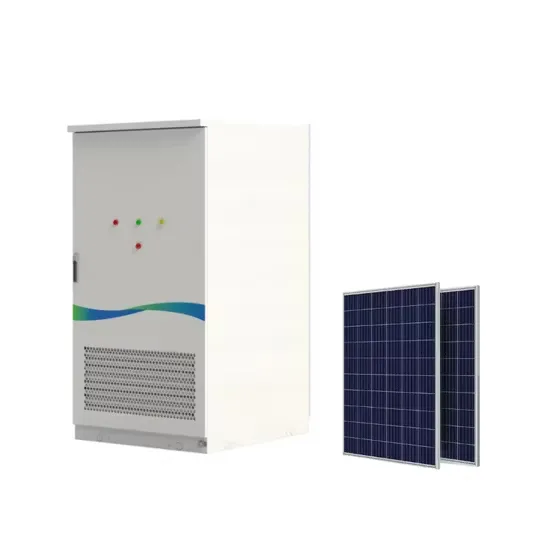

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.