Recommended Different Types Of Secondary Batteries

The best secondary battery depends on the specific application. Due to its capability of high energy density, lithium-ion batteries are often

Get a quote

Everything You Need to Know About Primary Battery

Both primary battery vs secondary battery have their advantages and disadvantages. Choosing the right one depends on the specific needs of

Get a quote

What is the meaning of secondary lithium battery pack The four

The internal resistance of the primary battery is much larger than the secondary battery, and its high-current discharge performance is not as good as that of the secondary

Get a quote

Lithium ion secondary batteries; past 10 years and the future

Years of assiduous efforts and researches to improve LIB performances enabled LIB to play a leading role in the portable secondary battery market. In this article, the past 10

Get a quote

Lithium-Ion Battery Basics

They offer long cycle life and no memory effect, but are more expensive than lead-acid batteries. Each type of secondary battery has its own advantages and limitations, making them suitable

Get a quote

What is a secondary lithium battery?

A secondary lithium battery pack refers to a lithium battery composed of several secondary battery packs, which is called a secondary lithium battery pack. A primary battery

Get a quote

What is a secondary lithium battery? The difference between

The internal resistance of the primary battery is much higher than that of the secondary battery, and its high-current discharge performance is not as good as that of the secondary battery.

Get a quote

The Heart of EVs: The Present and Future of

Reflecting the recent rise in demand for LFP batteries, the use of iron, which improves stability and durability, is also increasing. Anode

Get a quote

LITHIUM BATTERIES 101

Introduction A brief history and overview of advanced battery chemistry: The first lithium-ion battery prototype Popular lithium (ion) cell types: What are batteries made of? What are lead

Get a quote

Will secondary lithium battery packs leak

What causes a lithium ion battery to break? Abbreviation: LIB, lithium-ion battery. Separator rupture caused by strong external forces such as squeezing and needling, separator melting

Get a quote

18650 Batteries

The 18650 is a lithium-ion battery classified by its size, which is slightly larger than a AA battery. The advent of the 18650 brought along a new age of li-ion power which continues today,

Get a quote

Everything You Always Wanted to Know About Secondary Batteries

Lithium-ion battery, one of the most typical form of second batteries, is known for its durability. Compared to other types of batteries with the same capacity, a lithium-ion battery

Get a quote

Types of Secondary Batteries – Electricity – Magnetism

Primary cells have better energy storage capacity, but secondary cells have better power output capabilities compared to primary cells and are used for

Get a quote

Everything You Always Wanted to Know About

Lithium-ion battery, one of the most typical form of second batteries, is known for its durability. Compared to other types of batteries with

Get a quote

Top UL Certifications You Need to Know for Lithium Batteries

Discover the key UL certifications for lithium batteries, from UL 2054, UL 2271 to UL 2580, ensuring safety and reliability in your battery-powered devices.

Get a quote

Secondary Battery | Rechargeable Battery | EaglePicher

Explore EaglePicher''s experience in creating secondary batteries or lithium-ion battery rechargeable. Learn more about our secondary battery technology today!

Get a quote

What Is Secondary Battery? [Updated On

The design choices made when creating a secondary battery can have a significant impact on its performance and lifespan. For instance, choosing lithium-ion chemistry

Get a quote

The Heart of EVs: The Present and Future of Secondary Batteries

Reflecting the recent rise in demand for LFP batteries, the use of iron, which improves stability and durability, is also increasing. Anode materials are most commonly made

Get a quote

Design and Key Points for Selecting Secondary Battery Packs

Secondary battery packs are rechargeable power sources used in a multitude of devices and applications. Unlike primary batteries, which are meant for single use, secondary

Get a quote

Amazon : Lithium Battery Packs

2 Pack 12V 10Ah Lithium Ion LiFePO4 Deep Cycle Battery, 2000+ Cycles Rechargeable Battery for Solar/Wind Power, Scooters, Lighting, Power Wheels, Fish Finder Built-in 10A BMS 1K+

Get a quote

Recent Advances in Achieving High Energy/Power

This review comprehensively addresses challenges impeding the current and near-future applications of Li–S batteries, with a special focus on

Get a quote

Recommended Different Types Of Secondary Batteries

Therefore, this article will describe secondary batteries, their top handpicked choices, and what they entail. It will also address some of the most asked questions regarding

Get a quote

Lithium Batteries: Safety, Handling, and Storage

Lithium Cell Types Battery technology has seen very rapid development, with a proliferation of different technologies and types of batteries, in terms of construction and materials used. It is

Get a quote

Types of Secondary Batteries – Electricity – Magnetism

Primary cells have better energy storage capacity, but secondary cells have better power output capabilities compared to primary cells and are used for high-power applications. Secondary

Get a quote

6 FAQs about [Is the secondary lithium battery pack durable ]

Can secondary lithium batteries be rechargeable?

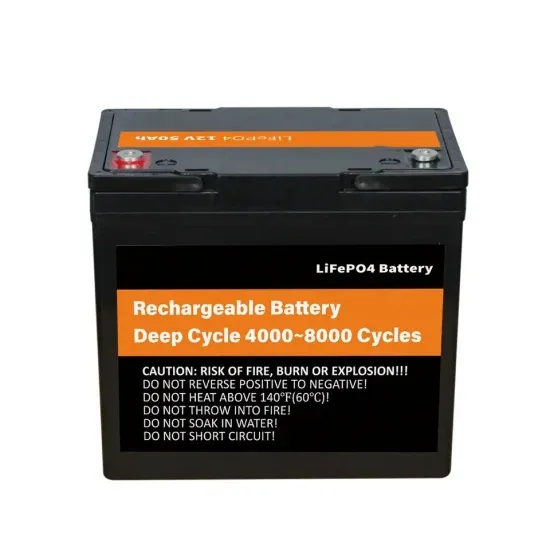

Thus, secondary batteries with metallic lithium negative electrodes have attracted much attention as a candidate for the battery with high energy density, and much effort has been made in developing secondary lithium batteries. Many practical problems, however, have been encountered in development of rechargeable lithium batteries.

What is a lithium based secondary battery?

Compared to regular batteries, lithium-based secondary batteries produce higher voltages with less weight. The voltage of a standard battery is at about 1.3 to 2 volts, whereas a lithium-containing battery generates 3-plus volts of electricity. In addition, it is smaller and lighter than other metal ions, resulting in high energy density per unit.

What makes a good secondary battery?

The design choices made when creating a secondary battery can have a significant impact on its performance and lifespan. For instance, choosing lithium-ion chemistry typically offers a high energy density and long lifespan, making it ideal for devices like smartphones and laptops.

What is a secondary battery pack?

You add more batteries! Now, imagine these batteries are neatly packed together, working as a team. That’s essentially what a secondary battery pack is – a group of secondary batteries working together to provide more power. Battery packs are crucial in applications that require more power than a single battery can provide.

What is the difference between a second battery and a lithium ion battery?

Secondary batteries, on the other hand, can be used for 500 to 2,000 cycles, thus more economical and environmentally sustainable. Lithium-ion battery, one of the most typical form of second batteries, is known for its durability.

What are the characteristics of secondary batteries?

Key characteristics of secondary batteries include: While secondary batteries offer numerous advantages, they may have lower energy density and higher initial costs compared to primary batteries. Ongoing research focuses on improving their performance, safety, and sustainability to meet the growing demands of modern technology and energy systems.

Guess what you want to know

-

Imported and durable lithium battery pack

Imported and durable lithium battery pack

-

Lithium battery pack can be partially replaced

Lithium battery pack can be partially replaced

-

Cambodia pack lithium battery equipment

Cambodia pack lithium battery equipment

-

3-series lithium battery pack

3-series lithium battery pack

-

The resistance of a single lithium battery pack is too large

The resistance of a single lithium battery pack is too large

-

Lithium iron phosphate battery pack requires balanced voltage

Lithium iron phosphate battery pack requires balanced voltage

-

Pack lithium battery assembly price

Pack lithium battery assembly price

-

South America graphene lithium battery pack

South America graphene lithium battery pack

-

100kwh ultra-large capacity lithium battery pack

100kwh ultra-large capacity lithium battery pack

-

Pack lithium battery range

Pack lithium battery range

Industrial & Commercial Energy Storage Market Growth

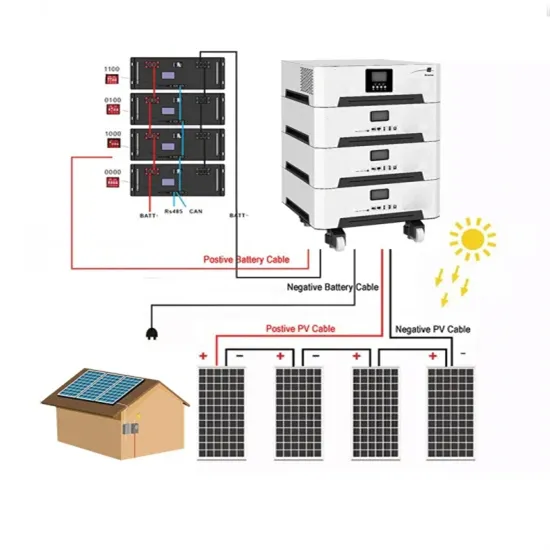

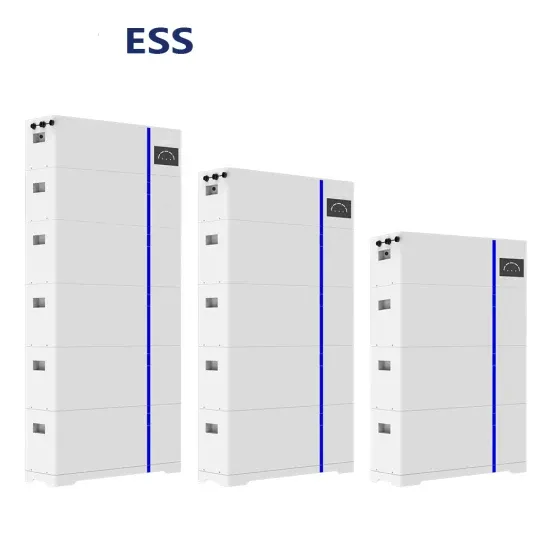

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.