What effect does the internal resistance of a lithium battery have on

The internal resistance of the lithium battery is too large or too small, and the impact on the battery is as follows: The internal resistance of a lithium battery is high and

Get a quote

Parameter variations within Li-Ion battery packs – Theoretical

Single lithium-ion cells within electric vehicles'' battery packs generally show variations in capacity and impedance due to the manufacturing process as well as operational

Get a quote

How Lithium-Ion Cell Sizes Impact Performance and

Understand how lithium-ion cell sizes impact energy density, usability, and safety. A comprehensive guide to choosing the right cell size for

Get a quote

What is Inconsistency in the Battery Packs? And how to solve it?

When used as a power source for drones, RC portable medical equipment, etc., the single lithium battery cannot meet the requirements of the high power and large capacity

Get a quote

Impact of Individual Cell Parameter Difference on the

Because the battery module is made up of a single battery connected in series, and the single battery is made up of a single cell connected in parallel, the impact of the capacity difference

Get a quote

Analysis of the inconsistency problem of Li-ion battery

In a series system, the difference in the internal resistance of a single battery will lead to the inconsistent charging voltage of each battery,

Get a quote

Analysis of the cell consistency in the lithium battery pack

After the lithium battery pack is put into use, the electrolyte density of each battery in the battery pack will change temperature and ventilation

Get a quote

Consistency evaluation of Lithium-ion battery packs in electric

The battery pack inconsistency is affected by factors such as battery capacity, internal resistance, and self-discharge rate during use, resulting in differences in aging and

Get a quote

Tattu 2300mAh 45C 4S 14.8v Lipo RC Airplane Battery Pack

Features: - Stable automatic stacking technology enables single-cell capacities of 1300mAh. - The most strict single cell capacity, voltage, resistance, discharge curve matching process. -

Get a quote

What are the Hazards and Problems of Inconsistent Lithium

Continuing the drama of the previous parallel connection situation, a battery pack D with deeper aging than all other battery packs appears in the whole battery pack, D has a

Get a quote

How to calculate the internal resistance of a battery pack

High internal resistance in a pack can make it less efficient, reduce its range, and create too much heat in EVs, which can be dangerous and shorten the battery''s life. Therefore, calculating and

Get a quote

The resistance of a single lithium battery pack is too large

High internal resistance in a pack can make it less efficient, reduce its range, and create too much heat in EVs, which can be dangerous and shorten the battery''s life. Therefore, calculating and

Get a quote

What cause the inconsistency of lithium battery and

Different battery capacity will lead to different discharge depth of each cell. The battery cell with small capacity and poor performance will reach

Get a quote

Large-capacity temperature points monitoring of lithium-ion battery

In addition, the embedded method of FBG sensor is difficult to achieve large-capacity temperature points monitoring, because the embedded single-point FBG sensor

Get a quote

What cause the inconsistency of lithium battery and

Different battery capacity will lead to different discharge depth of each cell. The battery cell with small capacity and poor performance will reach the full charge state ahead of

Get a quote

How to Charge Lithium-ion Battery Packs – Charging Methods, Charger

1. Charging new battery packs When you get a new lithium-ion battery pack, you don''t need to discharge and charge its first cycle fully. These cells have a maximum capacity

Get a quote

Pack Internal Resistance

The internal resistance of the battery pack is made up of the cells, busbars, busbar joints, fuses, contactors, current shunt and connectors. As the cells are

Get a quote

Battery Internal Resistance: Lithium & LiFePO4 Guide

Lithium-ion battery internal resistance is critical in determining battery performance, efficiency, and lifespan. Understanding what it is, how to

Get a quote

What is Inconsistency in the Battery Packs? And how to solve it?

High internal resistance in a pack can make it less efficient, reduce its range, and create too much heat in EVs, which can be dangerous and shorten the battery''s life. Therefore, calculating and

Get a quote

What Are the Main Factors Impacting Lithium Ion

Discover how temperature, usage patterns, design quality, and aging mechanisms are key factors affecting battery performance and lithium

Get a quote

What are the Hazards and Problems of Inconsistent Lithium Battery Pack

Continuing the drama of the previous parallel connection situation, a battery pack D with deeper aging than all other battery packs appears in the whole battery pack, D has a

Get a quote

Internal resistance matching for parallel-connected lithium

Here we present experimental and modeling results demonstrating that, when lithium ion cells are connected in parallel and cycled at high rate, matching of internal resistance is important in

Get a quote

Study on internal resistance of Li-ion power battery

From the C3 batch, the internal resistance of the battery suddenly increased significantly, with an average increase of 0.07 mΩ, and the spread became larger. The abnormal fluctuation of

Get a quote

Solving the battery cell-to-cell variations conundrum for

Because the size of lithium-ion cells is limited to a few hundred Watt-hours (Wh), large batteries are made up of hundreds, sometimes thousands of cells that are electrically connected in

Get a quote

Impact of Individual Cell Parameter Difference on the

Because the battery module is made up of a single battery connected in series, and the single battery is made up of a single cell connected in parallel, the

Get a quote

Analysis of the inconsistency problem of Li-ion battery packs

In a series system, the difference in the internal resistance of a single battery will lead to the inconsistent charging voltage of each battery, and the battery with large internal

Get a quote

A Beginner''s Guide to Lithium-Ion Battery Technology

Understand how lithium battery work, from energy storage to release, and explore their efficiency, safety features, and applications across

Get a quote

Key Factors Affecting Lithium-Ion Battery Resistance

What are the main factors affecting lithium-ion battery resistance? Several factors influence resistance, including temperature, current flow, material properties, manufacturing

Get a quote

6 FAQs about [The resistance of a single lithium battery pack is too large]

What is the resistance of a battery pack?

The resistance of a battery pack depends on the internal resistance of each cell and also on the configuration of the battery cells (series or parallel). The overall performance of a battery pack depends on balancing the internal resistances of all its cells.

How do you find the internal resistance of a battery pack?

If each cell has the same resistance of R cell = 60 mΩ, the internal resistance of the battery pack will be the sum of battery cells resistances, which is equal with the product between the number of battery cells in series N s and the resistance of the cells in series R cell. R pack = N s · R cell = 3 · 0.06 = 180 mΩ

What is internal resistance in a battery?

Internal resistance is a natural property of the battery cell that slows down the flow of electric current. It’s made up of the resistance found in the electrolyte, electrodes, and connections inside the cell. In single battery cells, this resistance decides how much energy is lost as heat when the battery charges and discharges.

How does ohmic internal resistance affect battery discharge power?

The difference between the terminal voltage of Cell 2 and Cell 1 is proportional to the Ohmic internal resistance. Therefore, the discharge amount of the series battery pack depends on Cell 2, and the Ohmic internal resistance can affect the discharge energy and discharge power of the battery pack at the same time.

How does a battery pack affect EV performance?

The overall performance of a battery pack depends on balancing the internal resistances of all its cells. High internal resistance in a pack can make it less efficient, reduce its range, and create too much heat in EVs, which can be dangerous and shorten the battery’s life.

How does ohmic resistance affect battery power index?

When cells are connected in series, the capacity difference of a single cell affects the battery pack’s energy index, and the capacity and Ohmic resistance differences of cells affect the battery pack’s power index.

Guess what you want to know

-

Moldova large single lithium battery pack

Moldova large single lithium battery pack

-

Battery pack single string lithium battery charging at home

Battery pack single string lithium battery charging at home

-

Lithium battery pack resistance

Lithium battery pack resistance

-

5v lithium battery pack with large capacity

5v lithium battery pack with large capacity

-

Chilean single lithium battery pack

Chilean single lithium battery pack

-

Large capacity 6v lithium battery pack

Large capacity 6v lithium battery pack

-

Lithium battery pack waterproof large

Lithium battery pack waterproof large

-

Single lithium battery pack manufacturer

Single lithium battery pack manufacturer

-

60v lithium battery pack manufacturer

60v lithium battery pack manufacturer

-

Assembly lithium battery pack manufacturers

Assembly lithium battery pack manufacturers

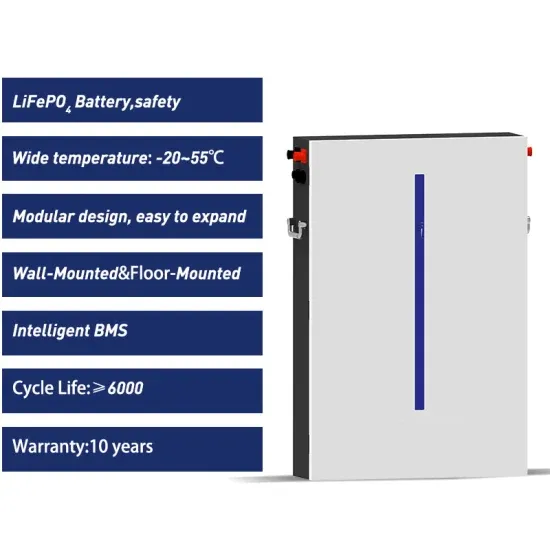

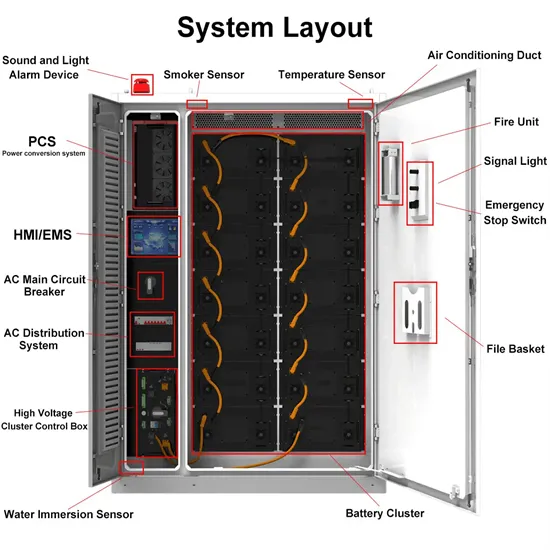

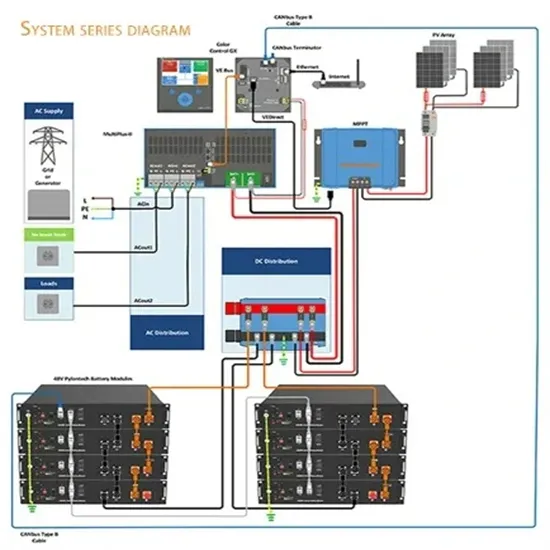

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

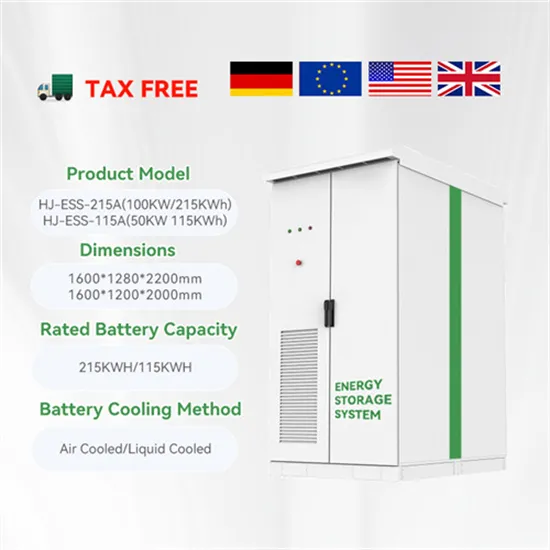

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.