Key Factors Affecting Lithium-Ion Battery Resistance

Internal resistance about Lithium battery directly impacts its performance and efficiency. It governs how energy flows and determines heat

Get a quote

Impact of Individual Cell Parameter Difference on the

Based on the designed series–parallel battery module model, the impact of Ohmic resistance difference, capacity difference, and polarization difference between individual cells on the

Get a quote

Key Factors Affecting Lithium-Ion Battery Resistance

Internal resistance about Lithium battery directly impacts its performance and efficiency. It governs how energy flows and determines heat generation during operation. For

Get a quote

Lithium Battery Internal Resistance: Effects on

Learn how lithium battery internal resistance affects performance, capacity, and lifespan, and discover ways to reduce resistance and improve

Get a quote

Study on battery pack consistency evolutions and equilibrium diagnosis

The consistency among lithium-ion battery pack is an important factor affecting their performance. The paper analyzes the impact sensitivity of parameters consistency including

Get a quote

Lithium Battery Internal Resistance and Its Impact

In evaluating battery performance, internal resistance (IR) is a critical factor, especially in lithium-ion batteries. It directly affects the battery''s efficiency, power output, and lifespan. Internal

Get a quote

Lithium Battery Internal Resistance: Effects on Performance

In lithium ion batteries, internal resistance causes energy losses in the form of heat during charge and discharge cycles. The higher the internal resistance, the greater the voltage

Get a quote

Battery Internal Resistance: Lithium & LiFePO4 Guide

Internal resistance varies significantly between battery types. Understanding these differences can help you select the right battery for specific applications. Low Internal

Get a quote

Understanding Lithium-Ion Battery Internal Resistance and Its Impact

On the other hand, colder temperatures can increase internal resistance, potentially affecting battery performance in devices used in extreme conditions. Minimizing Internal

Get a quote

The Effects of Resistance And On A Battery

Yes, it''s technically true that as most things get warmer, their resistance increases. But honestly, it takes a lot of temperature to cause enough of a change in resistance for it to

Get a quote

Why does a lithium-ion battery resistance has a different resistance

During charging, lithium ions migrate from the negative to the positive electrode, and the lower conductivity of the electrolyte increases resistance. During discharging, the ion

Get a quote

Impact of Individual Cell Parameter Difference on the

Based on the designed series–parallel battery module model, the impact of Ohmic resistance difference, capacity difference, and polarization difference

Get a quote

lithium ion

If I have lithium battery with some cells in series (same type, same manufacturer) - how much could they disbalance after one cycle? How much is too much? If, lets say, I charge

Get a quote

Consistency evaluation of Lithium-ion battery packs in electric

During the service process of lithium-ion battery packs, there is inconsistency among the cells in the pack, resulting in a significant decline in battery performance and

Get a quote

Internal Resistance Explained: Impact on 18650 and 21700 Batteries

Internal resistance (IR) in a battery pack refers to the resistance to the flow of electric current that occurs inside the battery itself. It can be thought of as the "friction" that impedes the movement

Get a quote

A Review of Lithium-Ion Battery for Electric Vehicle Applications

Among many kinds of batteries, lithium-ion batteries have become the focus of research interest for electric vehicles (EVs), thanks to their numerous benefits. However, there

Get a quote

Aging effect on the variation of Li-ion battery resistance as

Nowadays, lithium-ion batteries are widely employed in a lot of applications. Battery aging implies performance degradation of the battery itself. In particular, the battery aging

Get a quote

How to calculate the internal resistance of a battery cell

For a lithium-ion battery cell, the internal resistance may be in the range of a few mΩ to a few hundred mΩ, depending on the cell type and design. For

Get a quote

Lithium Battery Internal Resistance: Effects on

In lithium ion batteries, internal resistance causes energy losses in the form of heat during charge and discharge cycles. The higher the internal

Get a quote

Battery Internal Resistance: Lithium & LiFePO4 Guide

Internal resistance varies significantly between battery types. Understanding these differences can help you select the right battery for

Get a quote

Low complexity state-of-charge estimation for lithium-ion battery pack

Furthermore, it is difficult to achieve an accurate SOC estimation with less computational burden when the battery pack contains hundreds (or thousands) of cells. This

Get a quote

Estimation the internal resistance of lithium-ion-battery using a

Battery thermal management (BTM) is essential to ensure the safety of the battery pack of electric vehicles. For a variety of BTM technologies, the battery''s internal resistance

Get a quote

A Guide to Understanding Battery Specifications

Battery Basics Cell, modules, and packs – Hybrid and electric vehicles have a high voltage battery pack that consists of individual modules and cells organized in series and parallel. A cell is the

Get a quote

Why does a lithium-ion battery resistance has a

During charging, lithium ions migrate from the negative to the positive electrode, and the lower conductivity of the electrolyte increases

Get a quote

Lithium-Ion vs. Lead-Acid Batteries: A Comprehensive

In the world of energy storage, the choice between lithium-ion and lead-acid batteries is a critical decision for both consumers and industries.

Get a quote

The Impact of Increased Internal Resistance of Lithium Batteries

In the entire life cycle of lithium batteries, the increase of internal resistance is one of the core challenges that lead to performance degradation.

Get a quote

Optimization of lithium-ion battery pack thermal performance: A

Lastly, existing research overlooks the impact of electrical configuration on thermal properties, particularly in series-connected lithium-ion battery setups where voltage

Get a quote

The dynamic failure mechanism of a lithium-ion battery at different

The rapid development of lithium-ion batteries (LIBs) and their wide application in aerospace, automotive, electronic equipment and energy storage, and the consequent

Get a quote

6 FAQs about [Lithium battery pack resistance difference has a great impact]

How does internal resistance affect lithium battery performance?

Internal resistance impacts lithium battery performance in several ways: Reduced Efficiency: As internal resistance increases, more energy is lost as heat during charge-discharge cycles, which can reduce the available capacity of the battery.

Do lithium ion batteries have internal resistance?

Lithium batteries, particularly lithium ion cells, have revolutionized industries ranging from consumer electronics to electric vehicles (EV). However, despite their widespread use, many people overlook the crucial role that internal resistance plays in their overall performance.

What is internal resistance in a battery pack?

What is Internal Resistance? Internal resistance (IR) in a battery pack refers to the resistance to the flow of electric current that occurs inside the battery itself. It can be thought of as the “friction” that impedes the movement of charge carriers (ions) within the battery during discharge and charge cycles.

How to evaluate battery pack performance based on ohmic resistance difference?

The capacity utilization and energy utilization are used to evaluate the battery pack’s performance based on the above derivation results. When there is an Ohmic resistance difference between the individual cells, the individual cells with the highest Ohmic resistance limit the series-connected battery pack’s performance.

Are lithium ion batteries good?

Lithium-ion batteries offer the best balance of low internal resistance and efficiency, which is why they are preferred for most modern applications. However, lead-acid or NiMH batteries may still be viable options for low-cost or backup systems. Part 3. Factors influencing lithium-ion battery internal resistance Electrolyte

How does ohmic resistance affect battery performance?

When there is an Ohmic resistance difference between the individual cells, the individual cells with the highest Ohmic resistance limit the series-connected battery pack’s performance. When there is a capacity difference between individual cells, the battery pack’s performance is determined by the individual cells with the smallest capacity.

Guess what you want to know

-

Difference between battery pack and lithium battery

Difference between battery pack and lithium battery

-

Lithium battery pack resistance

Lithium battery pack resistance

-

The resistance of a single lithium battery pack is too large

The resistance of a single lithium battery pack is too large

-

Lithuania one lithium battery pack

Lithuania one lithium battery pack

-

Discharge price of lithium battery pack

Discharge price of lithium battery pack

-

What is the volume of a 24v 12A lithium battery pack

What is the volume of a 24v 12A lithium battery pack

-

Standard lithium battery pack factory price in Sierra Leone

Standard lithium battery pack factory price in Sierra Leone

-

10kva lithium battery pack

10kva lithium battery pack

-

South America graphene lithium battery pack

South America graphene lithium battery pack

-

100kwh ultra-large capacity lithium battery pack

100kwh ultra-large capacity lithium battery pack

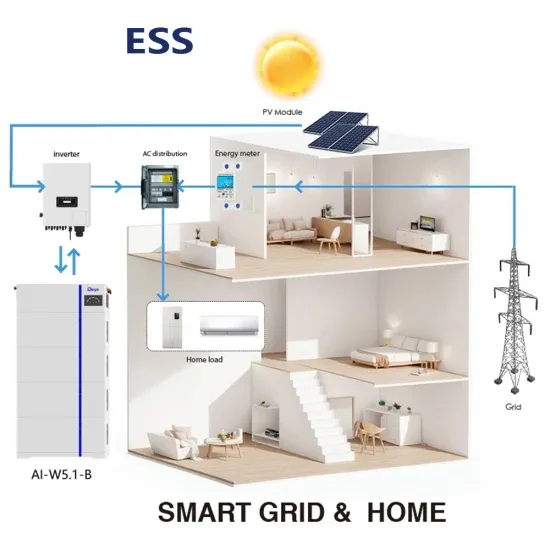

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.