Beginner-Friendly Tips for Assembling Lithium Battery

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get a quote

Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

Lithium-ion Battery pack which is comprised of assembly of battery modules is the main source of power transmission for electric vehicles.

Get a quote

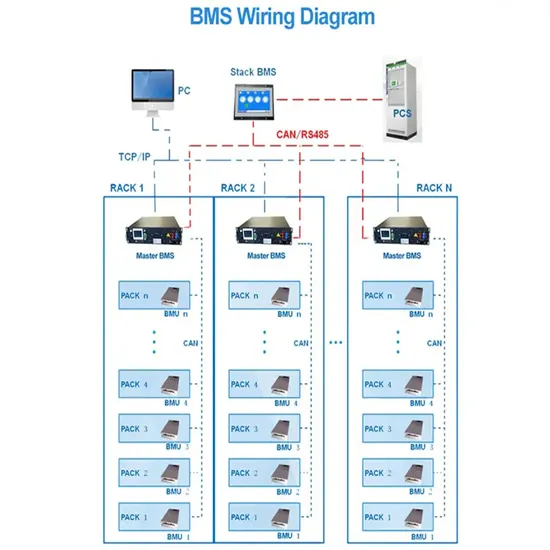

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get a quote

Surrogate model‐based heat dissipation optimization

A parametric study on thermal management of an air-cooled lithium-ion battery module for plug-in hybrid electric vehicles Modeling of

Get a quote

How to Assemble a Lithium Battery Pack Lithium Battery

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get a quote

Thermal Management of Air-Cooling Lithium-Ion Battery Pack

Lithium-ion battery packs are made by many batteries, and the difficulty in heat transfer can cause many safety issues. It is important to evaluate thermal performance of a battery pack in

Get a quote

Design and Optimization of Air-Cooled Structure in Lithium-Ion Battery Pack

This paper focuses on the thermal management of lithium-ion battery packs. Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery pack composed

Get a quote

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Assembling your own custom battery pack allows you to tailor a power solution to your specific needs, whether for an electric vehicle, solar storage system, robotics project or

Get a quote

Development of cooling strategy for an air cooled lithium-ion battery pack

This paper describes a cooling strategy development method for an air cooled battery pack with lithium-ion pouch cells used in a hybrid electric vehicle (HEV).

Get a quote

Assembling EV Lithium Battery Packs | Bonnen Battery

Before we dive into the nitty-gritty of assembling EV Lithium battery packs, let''s kick things off with a bang by checking out an explosive view – not

Get a quote

Assembling EV Lithium Battery Packs | Bonnen Battery

Before we dive into the nitty-gritty of assembling EV Lithium battery packs, let''s kick things off with a bang by checking out an explosive view – not literally, of course!

Get a quote

Energy‐Efficient Thermal Design of a Hybrid Air‐Cooled Lithium

A Review on Air Cooled and Air Centric Hybrid Thermal Management Techniques for Li-Ion Battery Packs in Electric Vehicles Synergistic Impact of Tube Configuration and

Get a quote

Optimization design for improving thermal performance of T-type air

In order to solve the problems of high battery temperature and poor temperature uniformity of the battery pack in the process of high-intensity operation, an air-cooled T-type

Get a quote

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get a quote

Air Cooling Concepts for Li-Ion Battery Pack in Cell Level

Three-dimensional numerical study of the effect of an air-cooled system on thermal management of a cylindrical lithium-ion battery pack with

Get a quote

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

In this step-by-step guide, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high-performance battery.

Get a quote

Beginner-Friendly Tips for Assembling Lithium Battery Packs

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get a quote

Design and Optimization of Air-Cooled Structure in Lithium-Ion

This paper focuses on the thermal management of lithium-ion battery packs. Firstly, a square-shaped lithium iron phosphate/carbon power battery is selected, and a battery pack composed

Get a quote

Lead-acid Lithium Battery Assembly Line Pack Square Shell Air Cooled

Lead-Acid Lithium Battery Assembly Line PACK Square Shell Air Cooled Energy Storage Module Production Line No reviews yet Guangdong Weitopu Automation Intelligent Manufacturing Co.,

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get a quote

How to Assemble a Lithium-Ion Battery Pack with a

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get a quote

An optimization study on the performance of air-cooling system

The impact of different airflow organizations on the cooling efficiency of the battery pack air-cooling system is investigated.

Get a quote

Development of cooling strategy for an air cooled lithium-ion

This paper describes a cooling strategy development method for an air cooled battery pack with lithium-ion pouch cells used in a hybrid electric vehicle (HEV).

Get a quote

How to Assemble a Lithium Battery Pack Lithium Battery Assembly

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get a quote

The Ultimate Guide For Lithium-Ion Battery Packs Components

This in-depth guide explores lithium-ion battery packs from the inside out. Learn about the key components like cells, BMS, thermal management, and enclosure.

Get a quote

The Handbook of Lithium-Ion

The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and Terminology

Get a quote

CN116632407A

The application discloses the technical field of cooling of lithium battery packs, in particular to an air-cooled lithium battery pack which comprises an assembling plate, a...

Get a quote

Assembling EV Lithium Battery Packs | Bonnen Battery

Assembling EV Lithium Battery Packs: Unpacking the Secrets of Bonnen Battery Production Before we dive into the nitty-gritty of assembling EV Lithium battery packs, let''s

Get a quote

6 FAQs about [Assembling the air-cooled lithium battery pack]

Can air cooled battery pack improve temperature uniformity?

An optimal design concept of air-cooled battery pack has been proposed. The cooling strategy to improve battery temperature uniformity has been studied. This paper describes a cooling strategy development method for an air cooled battery pack with lithium-ion pouch cells used in a hybrid electric vehicle (HEV).

What is a battery cooling system?

Accordingly, a cooling system is typically employed with the battery cells in the battery pack. A typical air cooled battery pack includes single or multiple strings of battery cells, a plurality of spaced apart battery cooling plates, cooling ducts, and control modules.

Do cooling strategies affect battery pack thermal behavior?

Analytical DOE studies are performed to examine the effects of cooling strategies including geometries of the cooling duct, cooling channel, cooling plate, and corrugation on battery pack thermal behavior and to identify the design concept of an air cooled battery pack to maximize its durability and its driving range. 1. Introduction

Why is temperature uniformity important in a lithium-ion battery pack?

The challenges associated with the temperature uniformity across the battery pack, the temperature uniformity within each individual lithium-ion pouch cell, and the cooling efficiency of the battery pack are addressed.

How to improve the temperature non-uniformity of a modified battery pack?

Since the lumped temperatures of battery cells at inlet side are still about 3 °C higher than those of battery cells at the opposite side ( Fig. 12 ), the temperature non-uniformity of the modified battery pack can be improved by further reducing the pressure of the lower duct near the closed end.

How can battery pack thermal model be correlated with physical tests?

After the battery pack thermal model is correlated to physical tests, analytical DOE studies are performed to effectively identify the cooling strategy to minimize battery cell lumped temperature, battery cell temperature variation across the pack, and total pressure drop of the pack.

Guess what you want to know

-

Assembling the components of a 60v 25a lithium battery pack

Assembling the components of a 60v 25a lithium battery pack

-

Panama Solar Lithium Battery Pack Introduction

Panama Solar Lithium Battery Pack Introduction

-

Reference price of good lithium battery pack in Côte d Ivoire

Reference price of good lithium battery pack in Côte d Ivoire

-

Canadian Mobile Home Lithium Battery Pack

Canadian Mobile Home Lithium Battery Pack

-

Maldives ultra-large capacity lithium battery pack

Maldives ultra-large capacity lithium battery pack

-

Syrian lithium battery pack supplier

Syrian lithium battery pack supplier

-

Embedded lithium battery pack

Embedded lithium battery pack

-

12v 25ah lithium battery pack production

12v 25ah lithium battery pack production

-

What accessories does a lithium battery pack consist of

What accessories does a lithium battery pack consist of

-

Timor-Leste lithium battery pack 200ah

Timor-Leste lithium battery pack 200ah

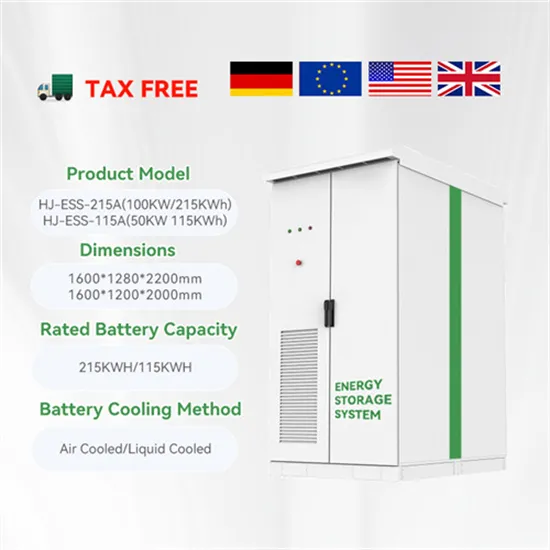

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.