How to Assemble a Lithium-Ion Battery Pack with a

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get a quote

E-CELLS FIVE STAR Battery Pack 60V 20AH

Made in America with Samsung and LG cells. Direct Replacement. The ultimate lithium battery for your adventures! Introducing the E-CELLS FIVE STAR

Get a quote

An Exhaustive Guide To Building 18650 Packs

Part two takes us through all the technical details and theory, from lithium-ion chemistry to battery management systems and spot-welding nickel

Get a quote

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring

Get a quote

How to Build a Lithium Ion Battery Pack? A Step by

Proper assembly will not only produce a battery that can function properly, but also help keep us safe while using the lithium-ion battery pack.

Get a quote

How Are Lithium Battery Packs Assembled?

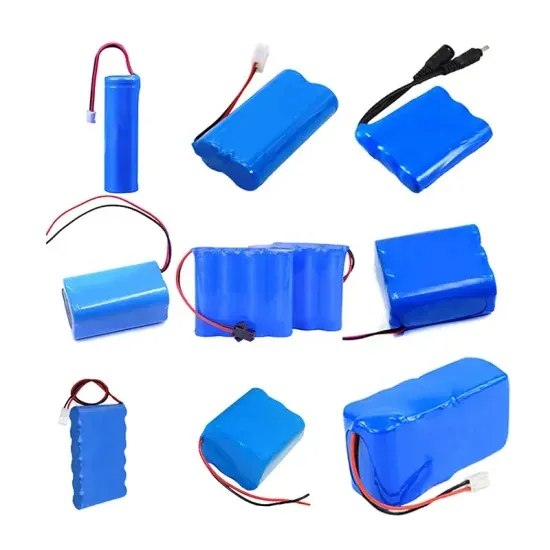

How Are Lithium Battery Packs Assembled? Lithium battery packs are essential components in various applications, from electric vehicles to renewable energy storage systems. They consist

Get a quote

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring these cutting-edge technologies to life.

Get a quote

The Most Detailed DIY Lithium Battery Pack Tutorial

Players who like drones, RC cars, RC boat, and riding electric bicycles, scooter and electric skateboards always lament the battery consumption is too fast, battery life is

Get a quote

DIY Professional 18650 Battery Pack

DIY Professional 18650 Battery Pack: The world is shifting away from fossil fuels and will one day become fully electric. In the present world, Lithium-ion is the

Get a quote

An Exhaustive Guide To Building 18650 Packs

Part two takes us through all the technical details and theory, from lithium-ion chemistry to battery management systems and spot-welding nickel busbars, while part one

Get a quote

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get a quote

How to Assemble a Lithium Battery Pack Lithium Battery

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get a quote

How to Build a Lithium Battery: Step-by-Step for Beginners

How to build a lithium battery? Our simple, step-by-step guide walks you through the process. Dive into this beginner project today!

Get a quote

Battery Pack Assembly : 5 Steps

Battery Pack Assembly: The goal of this project is to create a battery pack from purchased power cells. Is important to understand how cells can be connected

Get a quote

How Can You Craft a 60V Lithium Ion Battery Pack?

Crafting a 60V lithium-ion battery pack for your electric scooter or power tool can be a rewarding and cost-effective project. By following the step-by-step

Get a quote

BATTERY MODULE AND PACK ASSEMBLY PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Get a quote

How I Built a 60V 40Ah LiFePO4 Battery for My Electric Scooter!

Here is the step-by-step process of assembling a 60V 40AH lithium iron phosphate battery for electric two-wheelers. This DIY battery pack can be used for a v...

Get a quote

Battery Module: Manufacturing, Assembly and Test

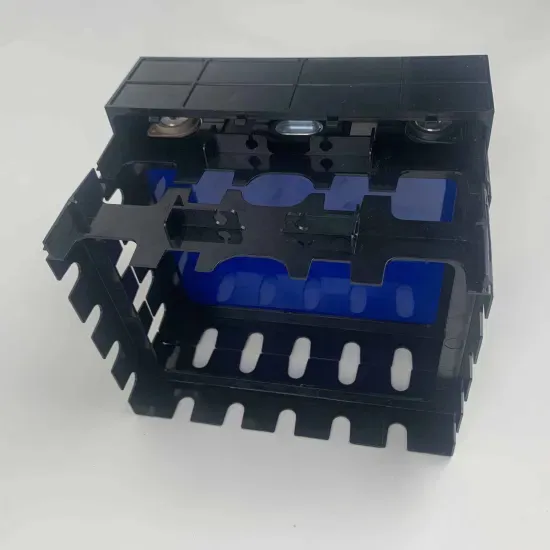

In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get a quote

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get a quote

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

Proper assembly will not only produce a battery that can function properly, but also help keep us safe while using the lithium-ion battery pack. Below is a list of materials and tools

Get a quote

Lithium Ion battery pack 60V 25Ah 3C For EV

Purchase a high-performance Lithium Ion battery pack 60V 25Ah 3C for your electric vehicle (EV). Reliable, efficient, and intended to deliver maximum power and

Get a quote

DIY 18650 Battery Pack Tutorial: Quick and Easy

Creating a DIY 18650 battery pack is an engaging and practical endeavor for electronics enthusiasts. This guide will detail the step-by-step

Get a quote

How to Assemble a Lithium Battery Pack Lithium Battery Assembly

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get a quote

How Can You Craft a 60V Lithium Ion Battery Pack?

Crafting a 60V lithium-ion battery pack for your electric scooter or power tool can be a rewarding and cost-effective project. By following the step

Get a quote

Understanding the Battery Cell Assembly Process

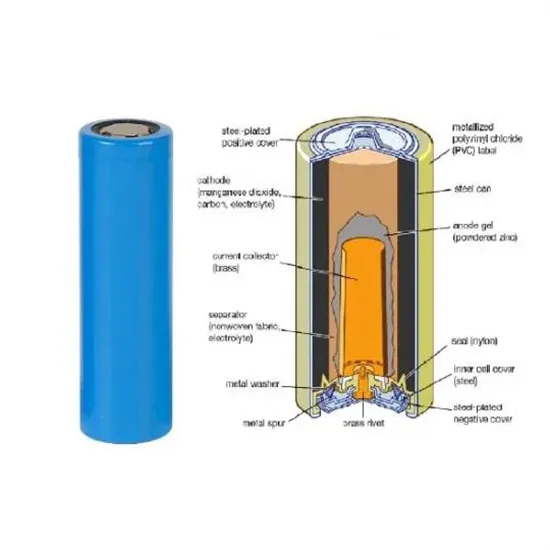

The production process of a lithium-ion battery cell consists of three critical stages: electrode manufacturing, cell assembly, and cell finishing.

Get a quote

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

In this step-by-step guide, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high-performance battery.

Get a quote

How Do You Assemble a 60V Lithium Ion Battery Pack?

How Do You Assemble a 60V Lithium Ion Battery Pack?Assembling your battery pack involves several steps:Prepare Cells: Gather your lithium ion cells and ensur...

Get a quote

6 FAQs about [Assembling the components of a 60v 25a lithium battery pack]

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

What is the voltage of a lithium battery?

The voltage of a lithium battery represents the potential difference between its positive and negative electrodes. The unit is volt (V). Different types of lithium batteries have different nominal voltages. Common ones are 3.6V, 3.7V, 7.2V, etc.

How to connect a lithium battery cell to a protective circuit board?

Use tape or other fixing methods to secure the protective circuit board to the lithium battery cell. This prevents it from loosening or shifting. Make sure there is no metal contact between the protective circuit board and the lithium battery cell to avoid short circuit or other safety issues. 5. Connect the wires

How to avoid a short circuit in a lithium battery?

A short circuit in a lithium battery can cause excessive current, causing fire and explosion. Therefore, when assembling and using a lithium battery pack, avoid bringing metal objects or conductive objects into contact with the positive and negative electrodes of the lithium battery to avoid short circuits. 4. Prevent vibration and shock

What does the capacity of a lithium battery mean?

The capacity of a lithium battery represents its ability to store and release electrical energy. The unit is ampere-hour (Ah). The larger the capacity, the more energy the battery can store and the longer it can be used. 2. Voltage The voltage of a lithium battery represents the potential difference between its positive and negative electrodes.

Guess what you want to know

-

60v 32ah lithium battery pack production

60v 32ah lithium battery pack production

-

Togo uses 17-string 60v lithium battery pack

Togo uses 17-string 60v lithium battery pack

-

60v lithium battery pack manufacturer

60v lithium battery pack manufacturer

-

60v 32ah lithium battery pack

60v 32ah lithium battery pack

-

Assembling the air-cooled lithium battery pack

Assembling the air-cooled lithium battery pack

-

South America graphene lithium battery pack

South America graphene lithium battery pack

-

Pack lithium battery assembly price

Pack lithium battery assembly price

-

Lithium battery pack capacity decreases

Lithium battery pack capacity decreases

-

Lithium battery pack voltage type

Lithium battery pack voltage type

-

Manufacturing 12v lithium battery pack

Manufacturing 12v lithium battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.