How High Voltage BMS Monitors Battery Performance and Health

A high voltage BMS serves multiple functions designed to optimize battery performance while safeguarding against potential hazards. By continuously monitoring critical

Get a quote

Battery Connectivity, Management, and Protection

The Role Connectivity Plays in Making High-Voltage EV Battery Packs Safer, More Eficient, and Longer-Lasting Electric vehicles have gone mainstream. Automotive industry pundits agree

Get a quote

1500 V Battery Energy Storage Reference Design

The RD-BESS1500BUN is a complete reference design bundle for high-voltage battery energy storage systems, targeting IEC 61508, SIL 2 and IEC 60730,

Get a quote

High Voltage BMS For Energy Storage System and LiFePo4 battery

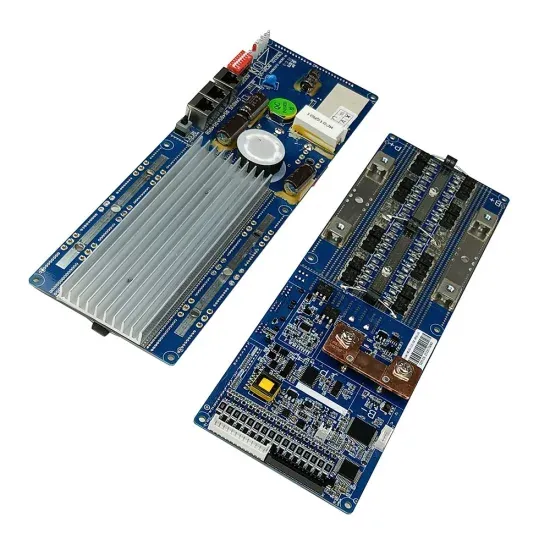

OSM High voltage solution is a decentralized BMS designed for high voltage applications. It has a Master-Slave topology, with Battery Monitoring Unit (BMU) as the BMS

Get a quote

What Is BMS in an Electric Vehicle (EV)?

Voltage detection circuit (for the battery module): Measures the voltage of the battery module and that of each battery cell Monitoring circuit (BMS circuit): Monitors states

Get a quote

How High-Voltage BMS Enhance Safety and Battery Lifetimes

By ensuring better battery-monitor accuracy and increasing system-level safety, the BMS helps maintain efficient energy usage and delays premature battery degradation, prolonging BESS

Get a quote

High Voltage Battery Management Reference Design

HIGH-VOLTAGE BMS REFERENCE DESIGN Robust and reliable analog solutions NXP HVBMS reference design is a scalable ASIL D architecture for high-voltage applications, composed of

Get a quote

BMS for High Voltage Batteries: Optimize your battery''s safety

Everything you need to know about BMS for high voltage batteries. An effective component to guarantee the safety and performance of your batteries.

Get a quote

High Voltage Battery Management System (HVBMS)

NXP proposes a scalable high voltage battery management system (HVBMS) reference designs with an ASIL D architecture, composed of three modules: battery management unit (BMU), cell

Get a quote

How to Choose From High Voltage BMS and Low

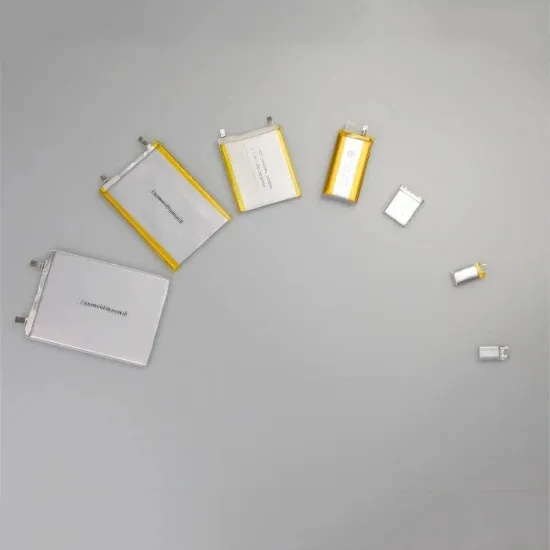

High voltage BMS is an electronic system dedicated to different types of batteries such as high voltage lithium ion battery, lithium iron

Get a quote

Key Challenges in High-Voltage Battery Management Systems

The Battery Management System (BMS) serves as the central intelligence of High-Voltage (HV) battery packs. It plays a significant role in the safety and efficiency of the overall Battery

Get a quote

Automotive battery management system (BMS)

Designed and rigorously tested for high-voltage batteries reaching up to 1200 V, our HV BMS offers a complete and ISO 26262 ASIL-D compliant system solution, covering BEVs, PHEVs,

Get a quote

Difference Between Centralized and Modular Battery

We offer modular low-voltage and high-voltage BMS solutions for various battery chemistries, including lithium-ion, lead-acid, and nickel-metal

Get a quote

High Voltage BMS For Energy Storage System and

OSM High voltage solution is a decentralized BMS designed for high voltage applications. It has a Master-Slave topology, with Battery

Get a quote

High Voltage Battery Management System for Electric

Nowadays, with the significantly increased Lithium-ion battery technology adoption in automobiles and energy storage, the integration,

Get a quote

How to Choose From High Voltage BMS and Low Voltage BMS?

High voltage BMS is an electronic system dedicated to different types of batteries such as high voltage lithium ion battery, lithium iron phosphate battery BMS, energy storage

Get a quote

Automotive battery management system (BMS)

Optimize battery performance and extend driving range with Infineon''s advanced automotive battery management system for monitoring, protection, and efficiency.

Get a quote

A Guide to High Voltage Battery Systems:

As the global electrification transition accelerates, high voltage battery systems are becoming critical in driving renewable energy storage and industrial

Get a quote

ENJBMS High Voltage Active Balancing BMS

Introduction: The ENJ Master Slave BMS High Voltage Series is designed for managing high-voltage battery systems, supporting voltages over 1000V and

Get a quote

How Much Do You Know About Battery Management System

The block diagram for a High Voltage BMS consists of essential components ensuring the optimal performance and safety of the battery pack. It begins with Cell Monitoring

Get a quote

High Voltage Battery Management System for Electric Vehicles

Nowadays, with the significantly increased Lithium-ion battery technology adoption in automobiles and energy storage, the integration, architecture, and design of an efficient,

Get a quote

High-Voltage Battery Management System

Designed specifically for lithium-ion battery chemistries, Nuvation Energy''s new fifth-generation battery management system supports up to 1500 V DC battery stacks and modules that use

Get a quote

6 FAQs about [High-voltage battery module and BMS]

What are battery management systems (BMS)?

Battery Management Systems (BMS) are the key to the safe, reliable and efficient functioning of the lithium-ion batteries.Especially When use a high voltage bms.

What is a high voltage BMS?

Nuvation Energy’s High-Voltage BMS provides cell- and stack-level control for battery stacks up to 1500 V DC. One Stack Switchgear unit manages each stack and connects it to the DC bus of the energy storage system.

What is a high-voltage battery management system (BMS)?

That’s where high-voltage Battery Management Systems (BMS) come into play. A well-designed BMS is the key to unlocking battery longevity, maximizing usable power, and ensuring operational reliability.

What is a high voltage battery management system?

A high voltage BMS typically manages the battery pack operations by monitoring and measuring the cell parameters and evaluating the SOC (State Of Charge) and SOH (State Of Health). The HV battery management system protects the cells in the battery pack by ensuring safe battery pack operations under the SOA (Safe Operating Area).

What is the classification of BMS for electric vehicles?

The classification of BMS for electric vehicles comes under 2 categories, i.e. LV (Low Voltage) and HV (High Voltage) A high voltage battery management system has numerous Li-ion cells connected in series and parallel to cumulatively account for the total voltage and capacity of the battery.

How does the nuvation energy high voltage BMS work?

From kWh to MWh, the Nuvation Energy High-Voltage BMS manages up to 1500 V DC per battery stack and up to 16 stacks in parallel with the addition of a Multi Stack Controller. Connects and disconnects a battery stack to the DC bus of the ESS in response to requests from system controllers.

Guess what you want to know

-

Burundi lithium battery BMS module manufacturer

Burundi lithium battery BMS module manufacturer

-

BAIC high-voltage battery replacement BMS

BAIC high-voltage battery replacement BMS

-

Colombian lithium battery BMS module

Colombian lithium battery BMS module

-

Simple lithium battery BMS management

Simple lithium battery BMS management

-

Burundi BMS Battery Management Control System

Burundi BMS Battery Management Control System

-

Palestine BMS Battery Management Control System

Palestine BMS Battery Management Control System

-

Somalia communication base station lead-acid battery module

Somalia communication base station lead-acid battery module

-

Energy storage battery high voltage control module

Energy storage battery high voltage control module

-

Barbados energy storage lithium battery BMS dealer

Barbados energy storage lithium battery BMS dealer

-

Brazil Battery Energy Storage BMS Standard

Brazil Battery Energy Storage BMS Standard

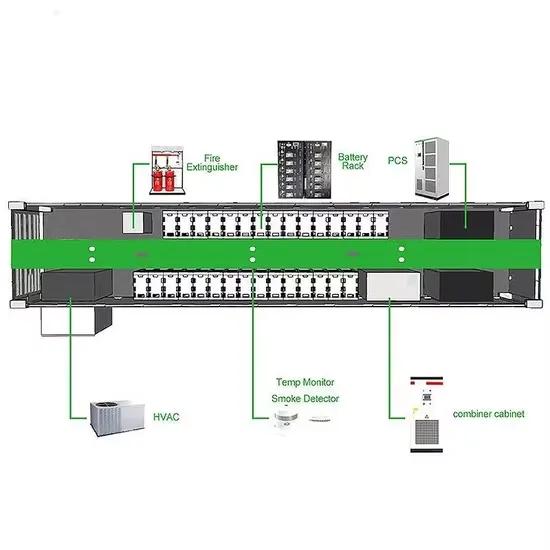

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.