Palestine BMS battery management test system characteristics

Battery Management System (BMS) testing is essential for optimizing battery performance and extending its lifespan. Proper BMS testing ensures that each cell within a battery pack

Get a quote

Government buildings

This comprehensive solution enhances operational efficiency, energy management, and overall control, contributing to a state-of-the-art broadcasting facility. Our commitment to delivering

Get a quote

Understanding the Role of a Battery Management System

The battery — a crucial element that determines the performance, safety, and efficiency of the EV — is at the core of these cars. The battery management system (BMS) is a sophisticated

Get a quote

What Is a Battery Management System (BMS)?

A battery management system (BMS) monitors and manages the operational variables of rechargeable batteries. Explore videos, examples, and documentation.

Get a quote

Controls and Battery Management Systems

UT researchers are leaders in model-based Battery Management Systems (BMS) for improved battery lifetime and performance and in the control, estimation and optimization of electric and

Get a quote

Battery Management System (BMS) in Battery Energy Storage Systems

Learn about the role of Battery Management Systems (BMS) in Battery Energy Storage Systems (BESS). Explore its key functions, architecture, and how it enhances safety,

Get a quote

What is a Battery Control Unit? (Types of Battery

A battery control unit (BCU) is a device that manages the charging and discharging of a lead acid battery. It is also known as a battery

Get a quote

Technical Deep Dive into Battery Management

A Battery Management System (BMS) is an electronic system designed to monitor, manage, and protect a rechargeable battery (or battery pack). It plays

Get a quote

Understanding Battery Management Systems: The Key to

Exencell, as a leader in the high-end energy storage battery market, has always been committed to providing clean and green energy to our global partners, continuously

Get a quote

Battery Management Systems in Electric Vehicles

Summary <p>A battery management system (BMS) is one of the core components in electric vehicles (EVs). It is used to monitor and manage a battery system (or pack) in EVs. This

Get a quote

Bess system components Palestine

In general, there are four key components of BESS - a battery system, an inverter or power conversion system (PCS), a battery management system (BMS), and an energy management

Get a quote

Battery management system and battery disconnect unit

The battery management system includes a battery control unit and multiple cell supervision circuits. The electronic disconnect unit serves as an all-in-one solution that integrates a battery

Get a quote

Characteristics of Palestinian BMS battery management system

Battery Management System: Components, Types and Objectives A Battery Management System (BMS) is an electronic control system that monitors and manages the performance of

Get a quote

Battery Management System (BMS) Architecture: A

The Battery Management System (BMS) is a crucial component in ensuring the safe and efficient operation of lithium-ion battery packs in electric

Get a quote

Battery Management Systems (BMS): A Complete Guide

What is a Battery Management System (BMS)? A Battery Management System (BMS) is an electronic system that manages a rechargeable battery by monitoring its state,

Get a quote

Battery Management Systems: Different Types and

Battery Management Systems (BMS) are essential for optimizing battery performance, safety, and lifespan. Choosing the right system depends

Get a quote

Battery Management Systems (BMS)

For the automotive engineer the Battery Management System is a component of a much more complex fast acting Energy Management System and must interface with other on board

Get a quote

Battery Management Systems (BMS)

It shows the three main BMS building blocks, the Battery Monitoring Unit (BMU), the Battery Control Unit (BCU) and the CAN bus vehicle communications network and how they interface

Get a quote

How Battery Management Systems (BMS) Prevent Battery

To maximize performance and safety, a Battery Management System (BMS) is a critical battery system component. The BMS monitors and manages various aspects of battery

Get a quote

Electra Control Systems®

Established in 2008, Electra Control Systems® is Palestine''s premier control and automation company, specializing in Building Management Systems (BMS).

Get a quote

Battery Management System (BMS) Detailed Explanation:

Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Get a quote

6 FAQs about [Palestine BMS Battery Management Control System]

What is a battery management system?

The battery management system includes a battery control unit and multiple cell supervision circuits. The electronic disconnect unit serves as an all-in-one solution that integrates a battery disconnect unit, a battery management system, and optionally the cell monitoring units. based on volume production possible due to global production network

What is a battery management system (BMS)?

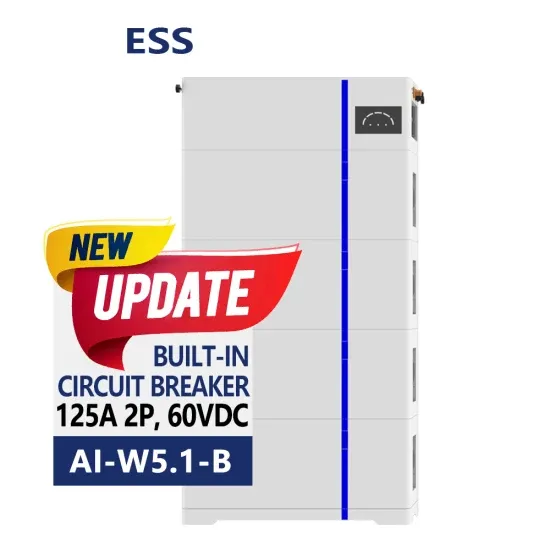

From real-time monitoring and cell balancing to thermal management and fault detection, a BMS plays a vital role in extending battery life and improving overall performance. As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving.

How will BMS technology change the future of battery management?

As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving. The integration of AI, IoT, and smart-grid connectivity will shape the next generation of battery management systems, making them more efficient, reliable, and intelligent.

What is a battery management system & electronical battery disconnect unit?

The battery management system and electronical battery disconnect unit consist of several components designed to monitor, manage, control, and disconnect the battery cells of a battery-electric or plug-in hybrid vehicle. The battery management system includes a battery control unit and multiple cell supervision circuits.

What makes a good battery management system?

A BMS must be designed for specific battery chemistries such as: 02. Power Consumption: An efficient BMS should consume minimal power to prevent draining the battery unnecessarily. 03. Scalability: For large-scale applications (EVs, grid storage), a scalable BMS is essential.

What is a battery balancing system (BMS)?

Cell balancing: Over time, the cells in a battery pack can become unbalanced, with some cells having higher or lower charge levels than others. A BMS can balance the cells by ensuring each cell is charged and discharged evenly, which helps maximize the battery run time.

Guess what you want to know

-

Burundi BMS Battery Management Control System

Burundi BMS Battery Management Control System

-

Guatemala BMS battery management control system architecture

Guatemala BMS battery management control system architecture

-

Russian BMS battery management control system brand

Russian BMS battery management control system brand

-

Swiss BMS battery management control system manufacturer

Swiss BMS battery management control system manufacturer

-

High-tech BMS battery management control system

High-tech BMS battery management control system

-

Chad BMS battery management control system composition

Chad BMS battery management control system composition

-

Uzbekistan BMS battery management control system

Uzbekistan BMS battery management control system

-

Lifeng BMS battery management system

Lifeng BMS battery management system

-

Professional BMS battery management system sales price

Professional BMS battery management system sales price

-

Is BMS battery management useful

Is BMS battery management useful

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.