Battery Management System (BMS): The Definitive

What is Battery Management System? How does BMS work? And the main function of a battery BMS. Find the lithium battery BMS manufacturer.

Get a quote

ExpertPower 12V 200Ah PRO LiFePO4 Battery, Bluetooth & Self

Cutting-Edge BMS: Our PRO LiFePO4 batteries come equipped with the newest version of our proprietary Battery Management System (BMS), precisely optimized to complement our

Get a quote

Basic principles of automotive modular battery

Battery management systems (BMS) with modular structure have become the most popular as control systems in electric vehicle battery

Get a quote

Battery Management System Standard

Well-designed battery management is critical for the safety and longevity of batteries in stationary applications. (Battery Life) New batteries have been developed recently that provide high

Get a quote

Battery Management System (BMS) | GERCHAMP

This article will explore the basic composition and working principles of the BMS structure and analyze its key role in battery management. Basic Composition of BMS Structure

Get a quote

Battery Management Systems (BMS): A Complete Guide

In this article, we will discuss battery management systems, their purpose, architecture, design considerations for BMS, and future trends. Ask

Get a quote

How Does A Battery Management System Work?

Dive deep into the intricate workings of Battery Management Systems (BMS). Learn how advanced monitoring, protection mechanisms, and smart algorithms work together

Get a quote

Battery Management Systems in Electric Vehicles

It is used to monitor and manage a battery system (or pack) in EVs. This chapter focuses on the composition and typical hardware of BMSs and their representative commercial products.

Get a quote

Battery Management System (BMS) Detailed Explanation:

Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Get a quote

Battery Management Systems (BMS): A Complete Guide

In this article, we will discuss battery management systems, their purpose, architecture, design considerations for BMS, and future trends. Ask questions if you have any

Get a quote

A review of battery energy storage systems and advanced battery

Battery management systems (BMS) are crucial to the functioning of EVs. An efficient BMS is crucial for enhancing battery performance, encompassing control of charging

Get a quote

What is a Battery Control Unit? (Types of Battery

A battery control unit (BCU) is a device that manages the charging and discharging of a lead acid battery. It is also known as a battery

Get a quote

Battery Management System (BMS) Architecture: A

In modern electric vehicles (EVs), the Battery Management System (BMS) is a critical component that ensures the safety, reliability, and

Get a quote

What is the composition of the battery management

The battery management system, namely Battery Management System, or BMS for short, is the core of the new energy vehicle energy management system.

Get a quote

Battery Management System (BMS) in Battery Energy Storage Systems

Learn about the role of Battery Management Systems (BMS) in Battery Energy Storage Systems (BESS). Explore its key functions, architecture, and how it enhances safety,

Get a quote

Battery Management Systems (BMS)

For the automotive engineer the Battery Management System is a component of a much more complex fast acting Energy Management System and must interface with other on board

Get a quote

Power battery management system principle, composition

As the "brain" of any battery-powered system, the BMS monitors, controls, and protects the battery pack, making it an indispensable component in modern energy storage

Get a quote

Battery Management System (BMS) Architecture: A Technical

In modern electric vehicles (EVs), the Battery Management System (BMS) is a critical component that ensures the safety, reliability, and performance of the battery pack. The

Get a quote

What Is A Battery Management System (BMS)?

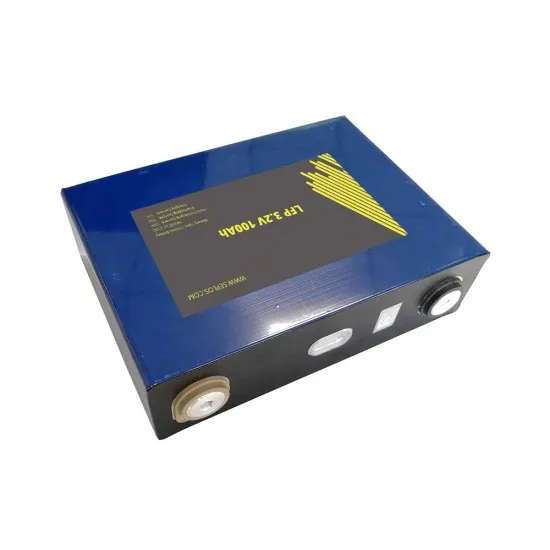

A Battery Management System (BMS) is an electronic control unit that monitors and manages lithium-ion or LiFePO4 battery packs. It ensures safe operation by balancing

Get a quote

Battery Management System (BMS) Architecture: A

The Battery Management System (BMS) is a crucial component in ensuring the safe and efficient operation of lithium-ion battery packs in electric

Get a quote

What is a Battery Management Controller? (Types of

Battery Management System Requirements A battery management system (BMS) is a critical component in any application where Lithium-ion

Get a quote

Understanding the Role of a Battery Management System

The BMS is typically an embedded system and a specially designed electronic regulator that monitors and controls various battery parameters (e.g. temperature, voltage, and current) to

Get a quote

A Detailed Schematic of a Battery Management System

A battery management system (BMS) is an essential component in modern battery-powered applications, such as electric vehicles and renewable energy systems. Its primary purpose is

Get a quote

Tesla''s Battery Management System: A Comprehensive Analysis

This section unpacks the nuances of battery types and their composition, deepening our understanding and appreciation of Tesla''s Battery Management System (BMS).

Get a quote

Comprehensive review of battery management systems for

Research into lithium-ion battery technologies for Electric Vehicles (EVs) is advancing rapidly to support decarbonization and mitigate climate change. A critical aspect in ensuring the

Get a quote

6 FAQs about [Chad BMS battery management control system composition]

What are the components of a battery management system (BMS)?

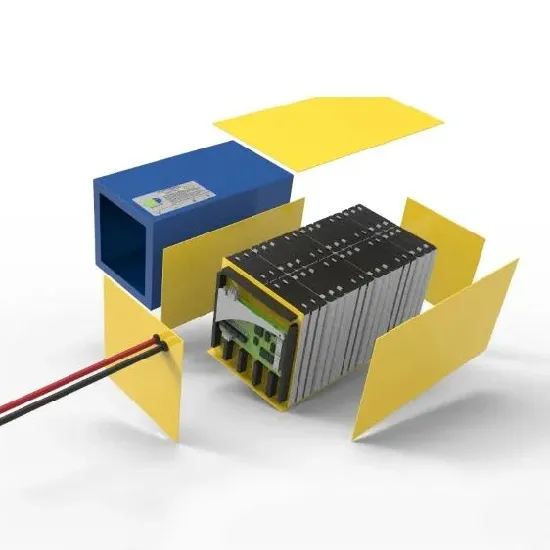

A typical BMS consists of: Battery Management Controller (BMC): The brain of the BMS, processing real-time data. Voltage and Current Sensors: Measures cell voltage and current. Temperature Sensors: Monitor heat variations. Balancing Circuit: Ensures uniform charge distribution. Power Supply Unit: Provides energy to the BMS components.

How will BMS technology change the future of battery management?

As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving. The integration of AI, IoT, and smart-grid connectivity will shape the next generation of battery management systems, making them more efficient, reliable, and intelligent.

What is a battery management system?

This includes everything from controlling the charging regime to planned maintenance. For the automotive engineer the Battery Management System is a component of a much more complex fast acting Energy Management System and must interface with other on board systems such as engine management, climate controls, communications and safety systems.

What makes a good battery management system?

A BMS must be designed for specific battery chemistries such as: 02. Power Consumption: An efficient BMS should consume minimal power to prevent draining the battery unnecessarily. 03. Scalability: For large-scale applications (EVs, grid storage), a scalable BMS is essential.

What is a BMS structure?

The basic composition and working principles of the BMS structure are closely related, working together to ensure the efficiency, safety, and longevity of battery systems. With the development of battery technology, the BMS structure will continue to play a crucial role in the field of battery applications.

What are the components of BMS architecture?

Key Components of the BMS Architecture Li-ion Cells (Battery Cells): The foundation of the system consists of lithium-ion cells that form the battery pack. These cells are arranged in series or parallel configurations depending on the desired voltage and capacity.

Guess what you want to know

-

Uzbekistan BMS battery management control system

Uzbekistan BMS battery management control system

-

Palestine BMS Battery Management Control System

Palestine BMS Battery Management Control System

-

Lesotho BMS battery management control system brand

Lesotho BMS battery management control system brand

-

Syria BMS battery management power system composition

Syria BMS battery management power system composition

-

High-tech BMS battery management control system

High-tech BMS battery management control system

-

Cuba BMS Battery Management Power System Company

Cuba BMS Battery Management Power System Company

-

Bms battery management system products

Bms battery management system products

-

Lead-acid battery management bms

Lead-acid battery management bms

-

Ivory Coast BMS battery management power system manufacturer

Ivory Coast BMS battery management power system manufacturer

-

Lifeng BMS battery management system

Lifeng BMS battery management system

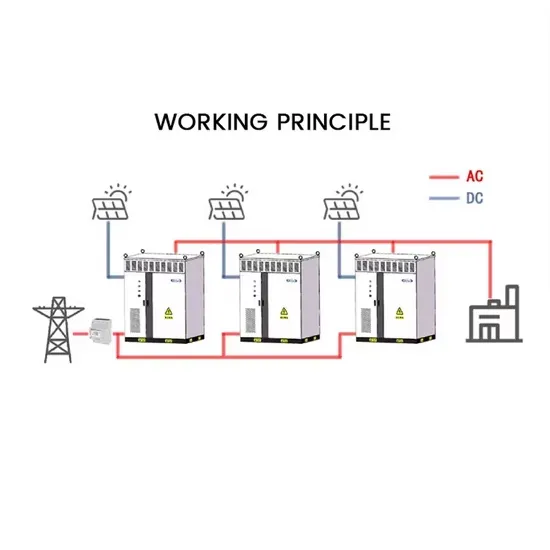

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

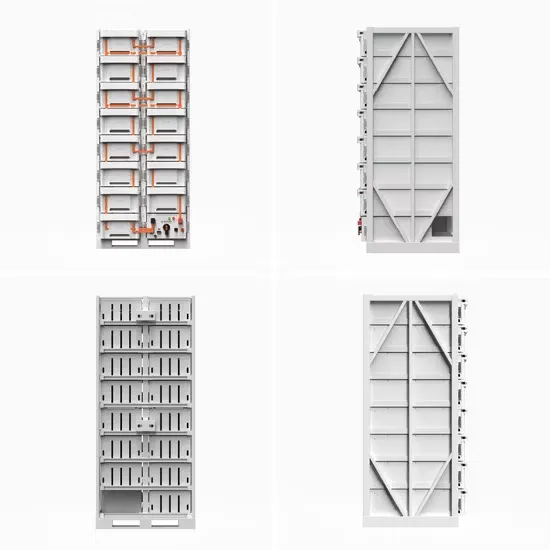

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.