Lead-Acid Battery Management System

Lead-acid BMSs are commonly used in EV and hybrid electric vehicles to power the starting, lighting and ignition (SLI) functions, but they can also be found in renewable energy

Get a quote

How to Choose from Types of Battery Management

Lead-acid BMS solutions are known for their cost-effectiveness, robustness, reliability, and well-established technology. However, lead-acid

Get a quote

About BMS for lead acid. : r/batteries

BMSes generally are not used with lead acid because they can be "safely" over charged. Over charging will drive off some water and that will need to be replaced. A BMS wouldn''t really

Get a quote

Lithium-Ion vs. Lead-Acid Batteries: How BMS Requirements

The core reason BMS requirements differ lies in the fundamental characteristics of each battery type. Lithium-ion batteries, known for their high energy density, are highly

Get a quote

Lithium-Ion vs. Lead-Acid Batteries: How BMS Requirements

Lead-acid batteries, while more robust and cost-effective, require different management strategies to prevent sulfation and stratification. This post will explore these

Get a quote

Is it necessary to install a battery management system for lead acid

The lead-acid battery BMS is responsible for regulating charging and discharging to enhance battery pack performance and lifespan, thus preventing overcharging and over

Get a quote

Why BMS is not required for lead acid battery?

Do you need a BMS for batteries in series? Well, actually, no – lithium batteries don''t need a battery management system (BMS) to operate. You can connect a few lithium

Get a quote

Why Lead-Acid Batteries Need Battery Monitoring

To overcome these challenges, integrating a Battery Monitoring System (BMS) is essential. This article explores why lead-acid batteries need

Get a quote

The most complete analysis of bms for lead acid battery

The battery management system (BMS) quickly and reliably monitors the state of charge (SoC), state of health (SoH) and state of function

Get a quote

A Complete Guide to Lead Acid BMS

A Lead-Acid BMS is a system that manages the charge, discharge, and overall safety of lead-acid batteries. Its primary function is to monitor the battery''s condition and

Get a quote

The Ultimate Guide to Lead Acid Battery BMS: Everything You

This article looks into the fundamentals of lead-acid battery BMS, including its components, functioning, importance and benefits, problems, developments, maintenance,

Get a quote

Do I Need a Battery Management System for Lead Acid Battery?

BMS stands for Battery Management System. A BMS is an electronic device that monitors and manages a battery system. It ensures that each individual cell in a battery pack

Get a quote

Lead-Acid Battery Management Systems: A Key to

In conclusion, Lead-Acid Battery Management Systems play a pivotal role in unlocking the full potential of lead-acid batteries. From precise monitoring and

Get a quote

BMS-icom Battery Monitoring System

See how the BMS-icom Battery Monitoring System is designed to monitor lead acid battery performance for 48V stationary battery systems with up to (4) 12V batteries.

Get a quote

Lead-Acid Battery Management Systems: A Key to Optimal...

In conclusion, Lead-Acid Battery Management Systems play a pivotal role in unlocking the full potential of lead-acid batteries. From precise monitoring and control to advanced diagnostics,

Get a quote

The most complete analysis of bms for lead acid battery

The battery management system (BMS) quickly and reliably monitors the state of charge (SoC), state of health (SoH) and state of function (SoF) based on starting capability to provide the

Get a quote

BMS For Lead-acid Battery

Lead-acid battery BMS is mainly responsible for monitoring, including basic battery parameters, charging and discharging time, ambient temperature etc. While other types of BMS tend to be

Get a quote

BMS for 12v Lead acid batteries

But the main question is can I add a 4s battery management system to keep all 4 cells balanced. A is it worth it with lead acid.... B can you get a system for 12v lead acid over

Get a quote

Battery Management Systems for Lead Acid Batteries

What is a Battery Management System? A Battery Management System is like a personal trainer for your batteries. Just like how a trainer helps you optimize your workouts and reach your

Get a quote

Overview of batteries and battery management for electric vehicles

Advances in EV batteries and battery management interrelate with government policies and user experiences closely. This article reviews the evolutions and challenges of (i)

Get a quote

Battery Chemistry Comparison, Capacity, Efficiency

However, lead acid is very cheap and typically does not require a battery management system (BMS) to monitor charge and discharge current

Get a quote

Do I Need a Battery Management System for Lead Acid Battery?

This article looks into the fundamentals of lead-acid battery BMS, including its components, functioning, importance and benefits, problems,

Get a quote

How to Choose from Types of Battery Management System (BMS)

Lead-acid BMS solutions are known for their cost-effectiveness, robustness, reliability, and well-established technology. However, lead-acid batteries have limited energy

Get a quote

What is a Battery Control Unit? (Types of Battery Management

A battery control unit (BCU) is a device that manages the charging and discharging of a lead acid battery. It is also known as a battery management system (BMS). The BCU

Get a quote

Battery Management | Analog Devices

Analog Devices offers a broad portfolio of battery charger IC devices for any rechargeable battery chemistry, including Li-Ion, LiFePO 4, lead acid, and

Get a quote

Why Lead-Acid Batteries Need Battery Monitoring Systems to

To overcome these challenges, integrating a Battery Monitoring System (BMS) is essential. This article explores why lead-acid batteries need a BMS, how it enhances

Get a quote

6 FAQs about [Lead-acid battery management bms]

What is a lead acid BMS?

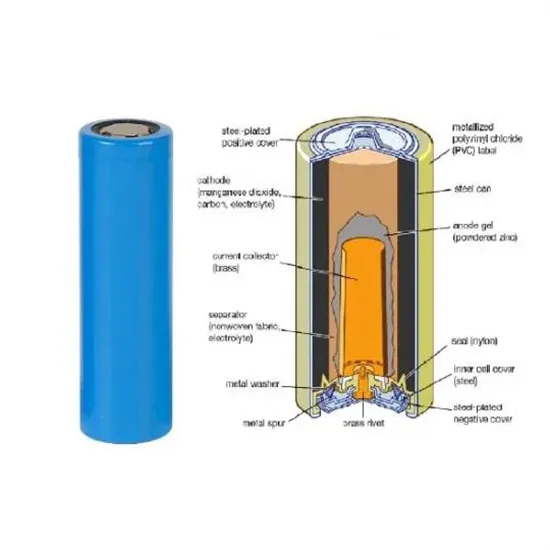

What is a Lead-Acid BMS? A Lead-Acid BMS is a system that manages the charge, discharge, and overall safety of lead-acid batteries. Its primary function is to monitor the battery’s condition and ensure it operates within safe parameters, ultimately extending the battery’s life and preventing failures.

What is a lead acid battery management system (BMS)?

Implementing a Lead Acid BMS comes with numerous advantages, enhancing both performance and safety: Extended Battery Life: By preventing overcharging and deep discharges, a BMS can significantly extend the life of a lead-acid battery. This is especially important in applications like solar storage, where cycling is frequent.

What is a lead-acid battery BMS?

Intelligent monitoring systems have now been integrated into lead-acid battery BMS, offering real-time data and insights into battery performance. With these systems, you can readily monitor key metrics such as voltage, temperature, and state of charge. Lead-acid battery BMS has also made important advances in battery diagnostics.

What is a lithium battery management system (BMS)?

While Lithium BMS has become more popular with newer battery technologies, a BMS for lead-acid battery systems remains vital for industries and applications that rely on traditional lead-acid power storage. Voltage Monitoring: Ensures each cell maintains the proper voltage levels, preventing overcharging or over-discharging.

How does a battery management system (BMS) work?

The BMS for lead-acid battery systems functions through constant monitoring and regulation during all stages of battery operation: charging, discharging, and standby. Charging Phase: When the battery is being charged, the BMS monitors the voltage and ensures that cells do not exceed their safe voltage limit.

What are the different types of battery management systems?

Battery Management Systems can be categorized based on Battery Chemistry as follows: Lithium battery, Lead-acid, and Nickel-based. Based on System Integration, there are Centralized BMS, Distributed BMS, Integrated BMS, and Standalone BMS. Balancing Techniques are categorized into Hybrid BMS, Active BMS, and Passive BMS.

Guess what you want to know

-

Syria BMS battery management power system composition

Syria BMS battery management power system composition

-

Lesotho BMS battery management control system brand

Lesotho BMS battery management control system brand

-

Sofia BMS battery management system manufacturer

Sofia BMS battery management system manufacturer

-

Chad BMS battery management control system composition

Chad BMS battery management control system composition

-

Remote BMS Battery Management System

Remote BMS Battery Management System

-

Cuba BMS Battery Management Power System Company

Cuba BMS Battery Management Power System Company

-

BMS battery management system price trend

BMS battery management system price trend

-

Swiss BMS battery management control system manufacturer

Swiss BMS battery management control system manufacturer

-

Swaziland Battery Management System BMS

Swaziland Battery Management System BMS

-

UAE BMS Battery Management Power Systems Company

UAE BMS Battery Management Power Systems Company

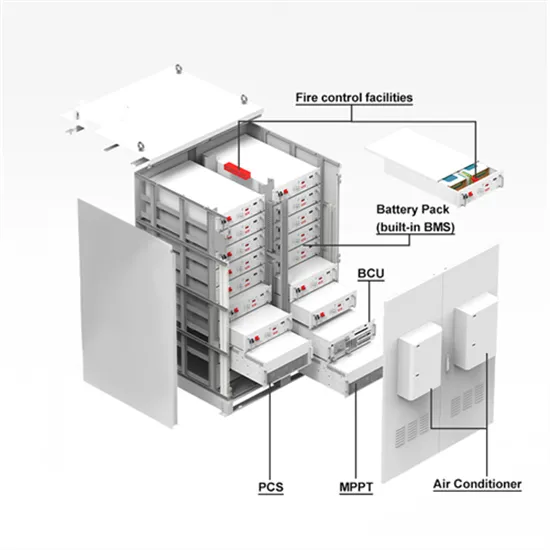

Industrial & Commercial Energy Storage Market Growth

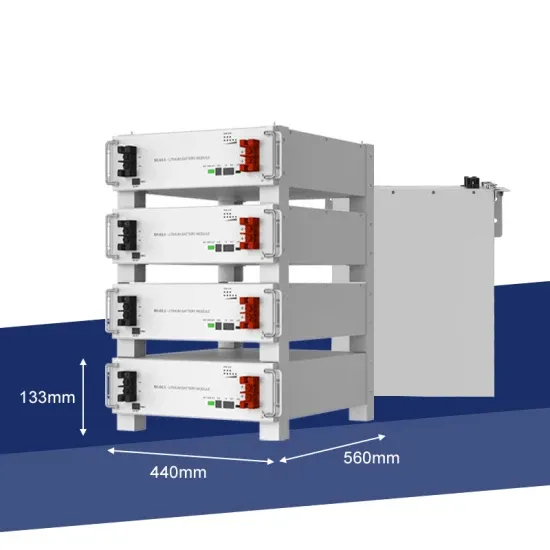

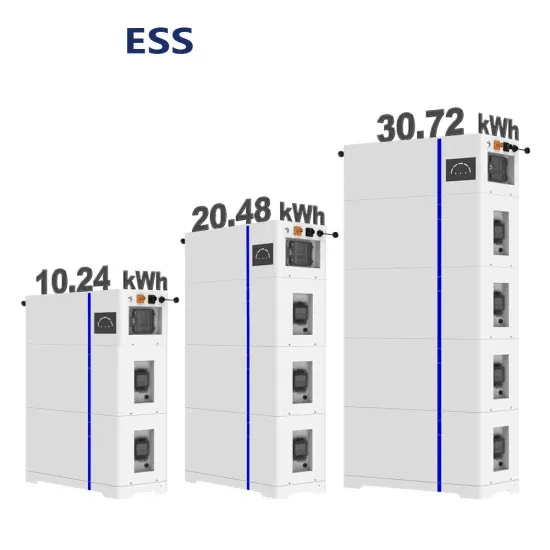

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

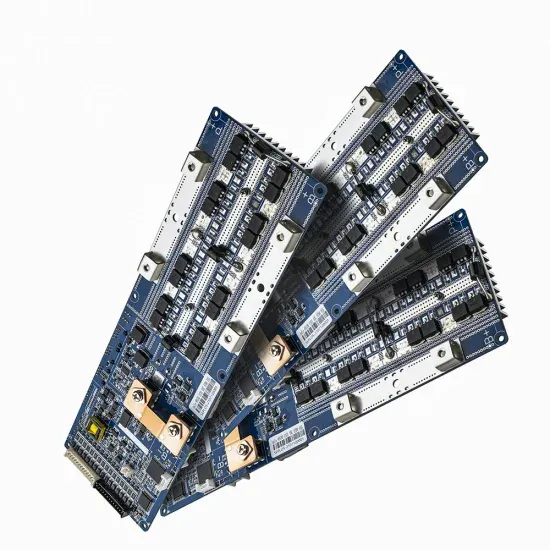

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.