MAN Truck & Bus tops out new high voltage battery

German commercial vehicle builder MAN Truck & Bus has topped out its new high voltage battery manufacturing plant in Bavaria. It said it will

Get a quote

High Voltage BMS For Energy Storage System and

OSM High voltage solution is a decentralized BMS designed for high voltage applications. It has a Master-Slave topology, with Battery

Get a quote

High Voltage BMS: A Comprehensive Guide to IC Selection

Mastering high-voltage battery management systems (BMS) is no longer optional – it is essential. This comprehensive guide equips you with the in-depth knowledge and insights

Get a quote

What Is the Battery Capacity of Nexon EV

The Tata Nexon EV has a battery capacity of 30.2 kWh (Prime) or 40.5 kWh (Max), offering up to 453 km range. But capacity alone doesn''t tell the full story. Many assume

Get a quote

High Voltage BMS: A Comprehensive Guide to IC

Mastering high-voltage battery management systems (BMS) is no longer optional – it is essential. This comprehensive guide equips you with the

Get a quote

ENJBMS High Voltage Active Balancing BMS

Introduction: The ENJ Master Slave BMS High Voltage Series is designed for managing high-voltage battery systems, supporting voltages over 1000V and

Get a quote

Industrial Battery Management System (BMS) devices

L9961 3-5 channel battery monitoring/balancing IC Accurate, real-time measurement of battery cell voltage, temperature and current balancing, and protection configurable predrivers for

Get a quote

Battery Management System: Components, Types

Definition of a Battery Management System A battery management system (BMS) is a sophisticated control system that monitors and manages

Get a quote

High Voltage Battery Management System (HVBMS)

The HWRD-HVBMSCC is a CAN FD-based high-voltage battery management system (HVBMS) hardware reference design. It provides a complete hardware solution including a battery

Get a quote

How High-Voltage BMS Enhance Safety and Battery Lifetimes

By ensuring better battery-monitor accuracy and increasing system-level safety, the BMS helps maintain efficient energy usage and delays premature battery degradation, prolonging BESS

Get a quote

Amazing TESLA High Voltage Battery Repair

Trust our technicians to fix your TESLA High Voltage Battery issues. 1-year warranty & reliable repairs to keep your Model S 3 X Y running smoothly.

Get a quote

BMS for Lithium-Ion Batteries: The Essential Guide to Battery

Comprehensive guide to BMS for lithium-ion batteries. Learn battery management system functions, safety features, and protection mechanisms in 2025.

Get a quote

Lithium Battery Repair by UpFix: Fixing BMS & Charging Issues

UpFix repairs lithium batteries for EVs, tools, and devices. Save money by fixing BMS and charging problems instead of replacing.

Get a quote

MAN celebrates topping-out ceremony for battery factory in

As early as April 2025, high-voltage batteries are to be produced industrially in Nuremberg on 17,000 m2. This will create nearly 350 jobs. MAN will thus be the first

Get a quote

MAN now assembles its own electric truck batteries

MAN uses NMC cell chemistry (nickel-manganese-cobalt) in its batteries, which has been specially adapted to the operation of commercial vehicles. The battery management

Get a quote

Automotive battery management system (BMS)

To get the most out of your battery, a battery management system (BMS) is required. Take a look at this video to understand how Infineon´s BMS system helps you protect the battery, balance

Get a quote

BAIC Battery Replacement Dubai

Our experienced technicians specialize in Baic battery replacement dubai, offering fast and professional service to get you back on the road without hassle. We only use high-quality, Baic

Get a quote

Future-oriented decision: MAN builds battery factory in Nuremberg

From the beginning of 2025, MAN Truck & Bus will manufacture high-voltage batteries for electric trucks and buses in large-scale production at its Nuremberg site.

Get a quote

MAN celebrates topping-out ceremony for battery

As early as April 2025, high-voltage batteries are to be produced industrially in Nuremberg on 17,000 m2. This will create nearly 350 jobs. MAN

Get a quote

Introducing the BAIC EU5 Chassis Training Bench

3. Replacement and testing of power battery module. 4. Measuring the battery pack''s voltage, current, and temperature through the diagnostic instrument. 5. Power-up logic

Get a quote

High Voltage BMS For Energy Storage System and LiFePo4 battery

OSM High voltage solution is a decentralized BMS designed for high voltage applications. It has a Master-Slave topology, with Battery Monitoring Unit (BMU) as the BMS

Get a quote

Lithium Ion Battery Management and Protection

This comprehensive BMS circuit diagram guide explains the features and working of a 4S 40A Battery Management System (BMS) commonly used

Get a quote

MAN Truck & Bus tops out new high voltage battery

German commercial vehicle builder MAN Truck & Bus has topped out its new high voltage battery manufacturing plant in Bavaria. It said it will make high-voltage batteries from

Get a quote

6 FAQs about [BAIC high-voltage battery replacement BMS]

What is a battery management system (BMS)?

The battery management system (BMS) continuously monitors the condition of the cells during operation. In the event of an unforeseen incident, for example, it takes internal measures to ensure a safe condition. In case of an accident, the BMS immediately disconnects the battery from the rest of the vehicle (high-voltage emergency shutdown).

What is a BMS for lithium-ion batteries?

A BMS for lithium-ion batteries acts as the "brain" of the battery pack, continuously monitoring, protecting, and optimizing performance to ensure safe operation and maximum lifespan. Understanding how BMS technology works is essential for anyone involved with lithium-ion applications.

What happens if a BMS exceeds a battery voltage limit?

The BMS continuously monitors both individual cell voltages and total pack voltage to prevent operation outside safe parameters. If limits are exceeded for a length of time, not only is a potentially expensive battery pack compromised, but dangerous thermal runaway conditions could ensue.

How accurate is a battery management system (BMS)?

The BMS employs multiple algorithms including coulomb counting, voltage-based estimation, and advanced techniques like Kalman filtering to provide precise charge level information. SOC accuracy directly impacts user experience and battery protection. Overestimation can lead to over-discharge, while underestimation reduces usable capacity.

Do batteries need BMS protection?

While basic protection circuits exist, they lack the comprehensive monitoring and management capabilities needed for safe operation. Even small consumer batteries benefit from BMS protection against overcharge, over-discharge, and thermal issues.

How does a BMS work?

In case of an accident, the BMS immediately disconnects the battery from the rest of the vehicle (high-voltage emergency shutdown). It also uses an intelligent heating and cooling system to keep the battery cells in an optimum temperature range at all times.

Guess what you want to know

-

Bms battery replacement

Bms battery replacement

-

High-voltage battery module and BMS

High-voltage battery module and BMS

-

BMS battery management system replacement

BMS battery management system replacement

-

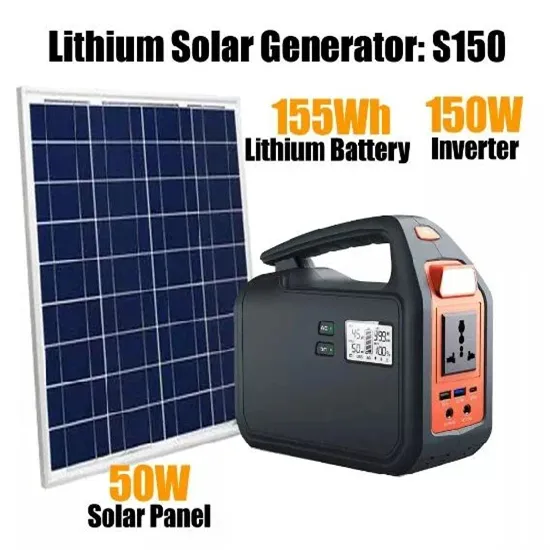

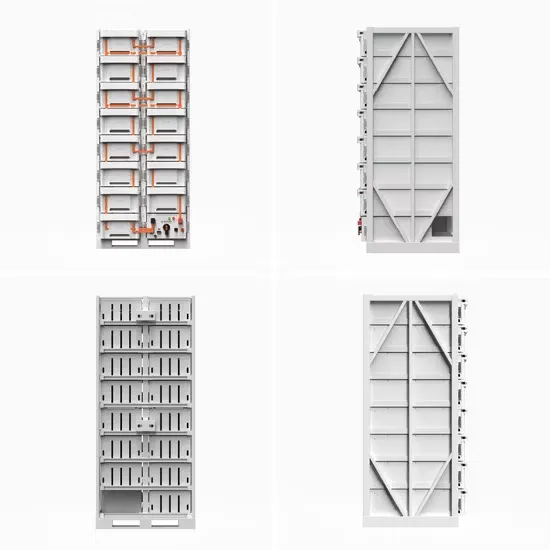

New Energy Battery Cabinet Quick Replacement System

New Energy Battery Cabinet Quick Replacement System

-

Battery BMS solution R

Battery BMS solution R

-

Estonia lithium iron phosphate battery bms wholesale

Estonia lithium iron phosphate battery bms wholesale

-

Morocco outdoor battery cabinet bms wholesale

Morocco outdoor battery cabinet bms wholesale

-

BMS battery management system price trend

BMS battery management system price trend

-

New Energy Battery Cabinet Replacement Conditions

New Energy Battery Cabinet Replacement Conditions

-

Greek lithium battery bms wholesale

Greek lithium battery bms wholesale

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.