Inverter Power Calculator, Formula,Inverter Calculation

Enter the values of rated inverter power, RP (W) in watts and efficiency, E to determine the value of Inverter power, P i (W). Imagine a solar panel system. The panels generate direct current

Get a quote

Determination of the Required Power Response of Inverters to

Mentioning: 6 - The decommissioning of conventional power plants and the installation of inverter-based renewable energy technologies decrease the overall power system inertia, increasing

Get a quote

Power Stack Reference Design for Inverter-Based Resources

In recent years, demands for power semiconductors, key devices for contributing to realizing a decarbonized society, have been rapidly expanding.

Get a quote

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power calculations and inverter

Get a quote

What Is Total Harmonic Distortion (THD) in Solar

Learn about the causes and effects of harmonic distortion in solar inverters. Discover ways to mitigate its impact and maintain power quality.

Get a quote

Inverter Analysis and Design

An important piece of information about an inverter stage is its static transfer characteristic, vOUT(vIN). To calculate this characteristic we sum the currents into the output node of the

Get a quote

Determination of Optimal DC/AC Ratio for Grid-Connected

Abstract Suitability evaluation of a location for solar power generation plant installation requires long-term measurements and calculations. The correct calculation of the project power and

Get a quote

Voltage Source Inverter Reference Design (Rev. E)

Control design of such inverter is challenging because of the unknown nature of load that can be connected to the output of the inverter. This reference design uses devices from the C2000

Get a quote

Inverter Model: Input and Output

Inverter Model: Input and Output On the input side (see also Inverter Operating Limits): - The inverter should search for the M aximum P ower P oint of the array (MPP tracking), i.e.

Get a quote

Determination of Smart Inverter Power Factor Control

Advanced inverters can improve integration of DER by reducing some of the adverse impacts from DER. Any reactive power (var) related inverter function used to mitigate adverse voltage

Get a quote

Determination of the power loss in inverters which supplies a

This paper presents a methodology for estimating the losses occurring inside an inverter with full controlled bridge supply for supplying a BLDC motor. The motor drives a small

Get a quote

Inverter Specifications and Data Sheet

This report provides a reference guide to the new capabilities and requirements listed in Clause 5 of IEEE Std 1547-2018 as well as considerations for their utilization.

Get a quote

Impedance-Based Method for Predictive Stability Assessment

Unlike conventional large power plants, PV power plants are constructed from a multitude of generating units. The electrical characteristics at the GCP primarily result from the

Get a quote

Implementation of output impedance in single‐phase

A strategy for the implementation of the output impedance in single-phase inverters connected in parallel with droop control for uninterruptible

Get a quote

Voltage Source Inverter Design Guide (Rev. B)

Voltage source inverters (VSI) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output. Control design of such inverter is challenging

Get a quote

How to choose the reference power value in a power control of

How to choose the reference power value in a power control of grid-connected inverters? Well, in that kind of control Pref and Qref are set points, it means you have to provide the values as...

Get a quote

Determination Of Inverter Capacity To Power The Main

The study focused on the determination of inverter capacity to power the main library of Federal Polytechnic, Ekowe, Bayelsa State. Three research questions were drawn from the study. The

Get a quote

Reference Design For Single-Phase Inverter

However, designing control for these inverters can be intricate due to the unpredictable loads that might be linked to the inverter''s output. Addressing these challenges

Get a quote

Power Stack Reference Design for Inverter-Based

In recent years, demands for power semiconductors, key devices for contributing to realizing a decarbonized society, have been rapidly expanding.

Get a quote

Reference Design For Single-Phase Inverter

However, designing control for these inverters can be intricate due to the unpredictable loads that might be linked to the inverter''s output.

Get a quote

PV array and inverter optimum sizing for grid-connected

Abstract This paper aims to select the optimum inverter size for large-scale PV power plants grid-connected based on the optimum combination between PV array and

Get a quote

A unified limited power reference generation for inverters under

Given these challenges, this paper introduces a unified limited power reference generation scheme for grid-following inverters that encompasses all potential operating

Get a quote

Grid Connected Inverter Reference Design (Rev. D)

Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation for the inverter:

Get a quote

Overview of Issues Related to IEEE Std 1547-2018 Requirements

This report provides a reference guide to the new capabilities and requirements listed in Clause 5 of IEEE Std 1547-2018 as well as considerations for their utilization.

Get a quote

6 FAQs about [Determination of inverter reference power]

What is a reference design for a single-phase inverter?

Addressing these challenges and needs, a reference design of a single-phase inverter has been introduced by Texas Instruments (TI). The reference design utilises a C2000 microcontroller (MCU) to control a single-phase inverter (DC/AC). It offers dual operational modes for the inverter.

How do you classify an inverter based on its power output?

Using the CEC efficiency, the input power to the inverter must be PIN=POUT/CEC Efficiency=3,300 W/0.945=3,492 W Inverters can be classed according to their power output. The following information is not set in stone, but it gives you an idea of the classifications and general power ranges associated with them.

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

What is a voltage source inverter?

Voltage source inverters (VSIs) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output. Control design of such inverter is challenging because of the unknown nature of load that can be connected to the output of the inverter.

What is a voltage source inverter (VSI)?

An IMPORTANT NOTICE at the end of this TI reference design addresses authorized use, intellectual property matters and other important disclaimers and information. Voltage source inverters (VSIs) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output.

How do you calculate inverter power?

Calculate the inverter power output. Given: RP (W) = 1000, E = 85%. Inverter power, P i (W) = RP (W) * E / 100 P i (W) = 1000 * 85 / 100 P i (W) = 850W. An inverter with an efficiency of 90% provides an output power of 450 watts (W). Calculate the rated power of the inverter. Given: P i (W) = 450W, E = 90%.

Guess what you want to know

-

12v inverter booster power supply

12v inverter booster power supply

-

How much power does the inverter supply

How much power does the inverter supply

-

Inverter power module maximum junction temperature

Inverter power module maximum junction temperature

-

Inverter temperature over-temperature limit power

Inverter temperature over-temperature limit power

-

Bangladesh DC power inverter brand

Bangladesh DC power inverter brand

-

How much power does a 1000va inverter have

How much power does a 1000va inverter have

-

How big a water pump can a 220v inverter power

How big a water pump can a 220v inverter power

-

Huawei Luxembourg Power Inverter

Huawei Luxembourg Power Inverter

-

Small power industrial inverter

Small power industrial inverter

-

Nepal Power Frequency Off-Grid Inverter Merchant

Nepal Power Frequency Off-Grid Inverter Merchant

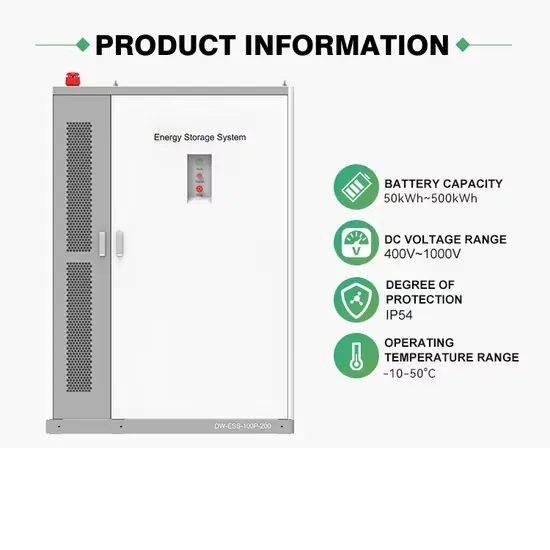

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

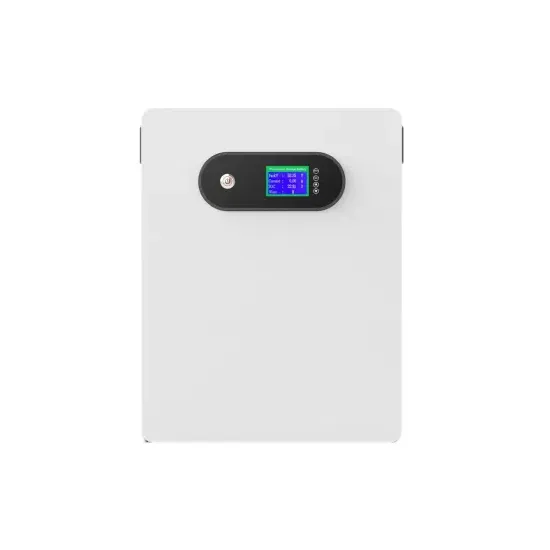

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.