Mecer Water Pump Solar Inverter 220V

The Aspire Solar Pump Inverter – The Single-phase in, single-phase out solar pump inverter is environmentally friendly with a long lifetime and lower

Get a quote

Water Pump and Inverter Compatibility: The Ultimate Guide

However, a common question arises: can water pumps run on inverters? In this comprehensive blog post, we will delve into the technicalities and practicalities of using

Get a quote

What inverter size would run this well pump

The fuse on my panel that is labelled ''water pump'' is a single 20 amp glass fuse, so I''m pretty sure it is 110/120 volt. I see a 4000 watt (8000 watt peak) inverter on Amazon

Get a quote

How to power my 1/2 hp 220V well pump from an inverter

A 12 volt system will work for a 1/2HP pump, but go for an inverter with the pure sine waveform and expect to draw around 1100 watts to run it. However, You will have more

Get a quote

How to Select Right Inverter Capacity for Your Home

How To Choose Right Inverter Capacity For Your Home, with the price of power inverters and batteries.The Ultimate Guide in Port Harcourt, Lagos, Abuja, Nigeria.

Get a quote

What Size Inverter Do I Need To Run A Pump?

Inverters come in various sizes, typically measured in watts (W) or kilowatts (kW). The size of the inverter should be equal to or slightly larger

Get a quote

Inverter power for water pumps: the ultimate guide to keep your

With the increasing popularity of alternative energy sources, the question of whether a water pump can run on an inverter has become a topic of interest. This blog post

Get a quote

How to power my 1/2 hp 220V well pump from an inverter

A 12 volt system will work for a 1/2HP pump, but go for an inverter with the pure sine waveform and expect to draw around 1100 watts to run it.

Get a quote

How to size battery and panels to run my well pump.

I have never had the nerve to just "give it a shot" and wire up the generator and turn on the inverter as I would rather not have to buy a new well pump if i calculated it wrong..

Get a quote

How to Convert an Electric Water Pump to Solar Power

4 days ago· To convert an electric water pump to solar power, you''ll need solar panels, a charge controller, a solar pump inverter, and optionally, batteries. The solar panels generate DC

Get a quote

What Size Inverter Do I Need To Run A Pump?

Inverters come in various sizes, typically measured in watts (W) or kilowatts (kW). The size of the inverter should be equal to or slightly larger than the calculated power

Get a quote

How To Run A Well Pump With A Portable Generator?

Since an uninterrupted electricity supply is mandatory to run the pump, a power outage can cause you no water in your home. However, to run your well pump during power

Get a quote

How do I convert my electric water pump to solar?

RPS can convert single phase electric water pumps up to 2 HP. How the Age of the pump effects system sizing older electric water pumps pull greater power than a newer, younger pump. Our

Get a quote

Aims 5000W 12VDC to 240VAC 60Hz Well Pump

The AIMS Power 5000 watt inverter with 240 volts AC output is a great choice for an off grid well pump that requires 240VAC to operate. The 240VAC supply is

Get a quote

How to size battery and panels to run my well pump.

I have never had the nerve to just "give it a shot" and wire up the generator and turn on the inverter as I would rather not have to buy a new well pump if i

Get a quote

What Inverter Size for Well Pump to Use?

A 4000 watt inverter is enough to run most 1.5 HP AC well pumps. These pumps consume 1500 watts but the surge wattage is double that, which is why a 4000 watt inverter is the best choice.

Get a quote

Can an inverter run a well pump?

The RPS 220V-to-Solar Conversion Kit allows for the powering of any existing 220V three wire motor over to solar. Works with both surface pumps and submersible pump as long as they

Get a quote

Can I Run a 220V Pump on Solar?

Now, this WaterSecure system is more of a classic style AC inverter, and that''s going to provide the power necessary to run your pump that requires batteries. But the good news is, with

Get a quote

Mini Split Power Requirements (With Wire Size and Breaker Size)

Power requirements for mini split systems are: 110/120 Volt: Most mini split systems up to 12,000 BTUs can use this voltage. 208/220 Volt: 12,000 BTU higher. But,

Get a quote

What size generator do I need to run my submersible well pump?

The amperage rating of the pump motor times the voltage would be the wattage that the pump needs once it has started up. But an electric motor needs an initial surge of power to

Get a quote

Solar Water Pump Sizing Calculator

The Solar Water Pump Sizing Calculator is an essential tool for individuals who rely on solar power to pump water. By providing the required input data, users can accurately calculate the

Get a quote

Is the Inverter 12v 220v 1500w suitable for powering a water pump?

As long as the pump''s power consumption doesn''t exceed the inverter''s 1500 - watt capacity, the inverter can provide the necessary power to keep the pump running. However, there are a few

Get a quote

6 FAQs about [How big a water pump can a 220v inverter power ]

How do I choose the right inverter size for my pump?

When selecting an inverter size for the pump, it is important to choose one that can handle the startup power as well as the running power demanded by the pump. Inverters come in various sizes, typically measured in watts (W) or kilowatts (kW).

Can a 4000 watt inverter run an AC well pump?

A 4000 watt inverter is enough to run most 1.5 HP AC well pumps. These pumps consume 1500 watts but the surge wattage is double that, which is why a 4000 watt inverter is the best choice. An AC well pump requires a lot of power to start up and run.

How many watts does an inverter need?

If you have a 1.5 HP pump, its running watts is going to be around 1500 watts, more or less. However, pump motors need a surge of power to start up. In a 1.5 AC pump this is about 3000 watts. Add 25% to 3000 watts and you get 3750 watts. Round that off to 4000, and that is the inverter you need.

Can a 12 volt inverter run a 1/2 HP pump?

A 12 volt system will work for a 1/2HP pump, but go for an inverter with the pure sine waveform and expect to draw around 1100 watts to run it. However, You will have more inverter options if you opt to go with a 24 volt system. You'll need one that can handle a surge around 3000 watts for 1/4 second just to start the pump.

Can a 1/2 HP water pump be powered with a 240 volt inverter?

Never assume, measure it . You could be wired for 240vAC. However with this being a 1/2hp pump you should be able to power it with a 2000w inverter if the voltage is correct. I power my 1/2hp 120vAC water pump with my 3000w (24vDC) without problems.

What size inverter do I Need?

To determine the appropriate size of the inverter needed to run a pump, it is necessary to calculate the power requirements of the pump. The power requirements can be calculated using the following formula: Power (Watts) = Voltage (Volts) x Current (Amps) First, you need to identify the voltage and current requirements of the pump.

Guess what you want to know

-

How big a water pump inverter should I buy for solar power

How big a water pump inverter should I buy for solar power

-

How big an inverter does a 220v power supply require

How big an inverter does a 220v power supply require

-

How much does a solar power station water pump inverter cost

How much does a solar power station water pump inverter cost

-

German solar water pump inverter photovoltaic power generation

German solar water pump inverter photovoltaic power generation

-

Can solar panels power a 12V water pump inverter

Can solar panels power a 12V water pump inverter

-

French solar high power water pump inverter

French solar high power water pump inverter

-

Outdoor power supply dedicated water pump inverter

Outdoor power supply dedicated water pump inverter

-

How often should a solar water pump inverter be replaced

How often should a solar water pump inverter be replaced

-

Solar water pump inverter connected to external power supply

Solar water pump inverter connected to external power supply

-

15w water pump inverter solar power

15w water pump inverter solar power

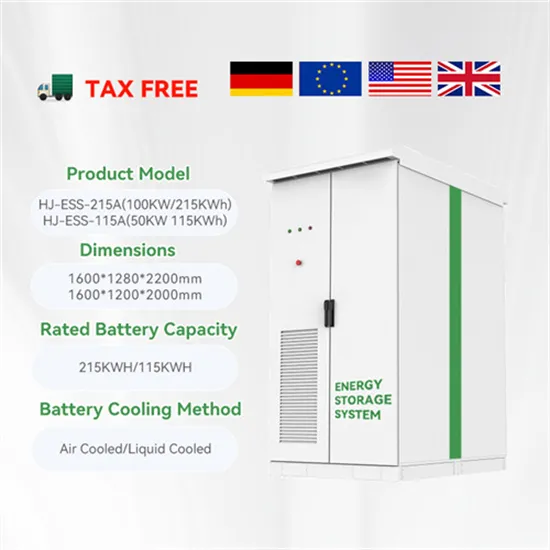

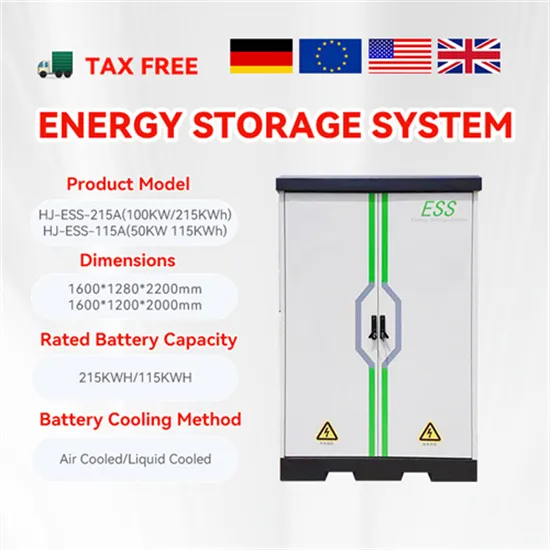

Industrial & Commercial Energy Storage Market Growth

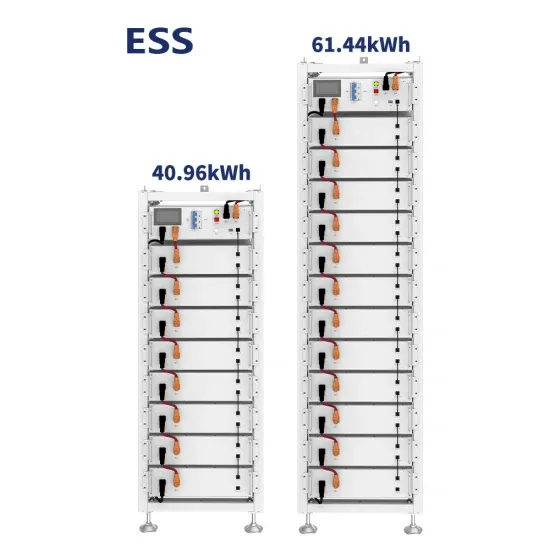

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.