Estimation of Junction Temperature in a Two-Level Insulated

This paper presents a method for junction temperature estimation using the mathematical thermal model in a two-level insulated-gate bipolar transistor (IGBT) inverter for

Get a quote

IGBT reliability analysis of photovoltaic inverter with reactive power

It is pointed out that the more the output reactive power of the photovoltaic inverter, the greater the maximum junction temperature and junction temperature fluctuation of the

Get a quote

Estimation of Junction Temperature and Power loss of IGBT

Hence, tools for accurate prediction of device power dissipation and 17 junction temperature become important in achieving optimized designs. At high switching frequencies, switching

Get a quote

Estimation of Power Losses, Temperatures and Power Cycle

Fuji Electric has released its IGBT simulator free of charge on the website. It simulates the power dissipation and the junction temperature of Fuji Electric IGBT modules that are incorporated

Get a quote

Online junction temperature estimation using integrated NTC

Drastic junction temperature fluctuations of power modules in electric vehicles (EV) have a significant impact on system reliability. This paper aims to estimate the junction

Get a quote

Real-time estimation of junction temperature in IGBT inverter with

This paper presents a simple parameterized power loss model for insulated gate bipolar transistor (IGBT) inverters, in which variables are relevant to the powertrain operation

Get a quote

Estimation Technique for IGBT Module Junction

As a result, module temperature monitoring techniques are critical in designing and selecting IGBT modules for high-power-density applications to guarantee that temperature stresses in

Get a quote

Real-time estimation of junction temperature in IGBT inverter with

However, the junction temperature rise due to power losses is one of the major factors limiting the inverter performance. Thus, real-time temperature monitoring and control is

Get a quote

Automotive IGBT chips feature 185 °C maximum

This module offers a power range of up to 250 kW within the 750 V and 1200 V classes, enhanced ease of use, and new features such as an

Get a quote

Calculating Junction Temperature Using a Module

Modern power semiconductor modules incorporate a temperature-sensitive resistive element (thermistor; NTC or PTC) soldered on the DBC substrate. Due to layout restrictions (e.g.

Get a quote

A Critical Review and Perspective on Thermal Management of Power

A cooling technology roadmap is defined for power electronics modules such as insulated gate bipolar transistors (IGBT) and wideband gap semiconductor modules

Get a quote

Higher Junction Temperature in Power Modules | Infineon

Data sheets of power devices show maximum ratings in junction temperature (TJ) of 150°C or 175°C.The maximum TJ for switching conditions, i.e. inverter operation is usually 25°C less.

Get a quote

Junction temperature estimation of a SiC MOSFET module for

A junction temperature estimating method based on digital twin and neural network was proposed for a high-power-density SiC MOSFET power module. Device power losses of

Get a quote

How long is your system going to last?

In the second test series the dependency of lifetime on junction temper-ature swing ∆Tj and mean junction temperature Tjm was investigated and the deduced model for Infineon''s 600 V / 650 V

Get a quote

A Study on Real Time IGBT Junction Temperature

This paper proposes a junction temperature estimation algorithm for the insulated gate bipolar transistor (IGBT) based on a power loss calculation

Get a quote

A Study on Real Time IGBT Junction Temperature Estimation

On this point, the proposed algorithm of this paper would be useful in estimating the junction temperature of a water-cooled inverter for automotive systems in real time, and preventing the

Get a quote

Comparison of junction temperature variations of IGBT modules

Results indicate that the operating conditions significantly impact the maximum junction temperature, the junction temperature increase rate, and the junction temperature

Get a quote

第1章

The power cycle life of the IGBT module depends on the temperature rise width (and the maximum temperature) during power cycle. Therefore, when there is only one temperature

Get a quote

Temperature Limits for Power Modules Part-1: Maximum Junction

This article features Infineon temperature limits for power module by understanding the effect of changing operating conditions and application parameters.

Get a quote

Pushing Module Power Density to the Limit

For each version of the module and each switching frequency, the highest current is identified where the maximum junction temperature of the module is less than 160°C. This

Get a quote

Estimation Technique for IGBT Module Junction Temperature in a

As a result, module temperature monitoring techniques are critical in designing and selecting IGBT modules for high-power-density applications to guarantee that temperature

Get a quote

Thermal management implementation method for IGBT

In this study, a thermal network model method and a temperature-sensitive electrical parameter (TSEP) method for junction temperature estimation are analyzed first. Aiming to limit the

Get a quote

IGBT Maximum Junction Temperature (Tjmax 185°C)

When an IGBT is used in an inverter or other device, energy is consumed, and heat is generated during switching and conduction. Operations exceeding the maximum junction temperature

Get a quote

Guess what you want to know

-

Module power and inverter power

Module power and inverter power

-

Inverter maximum power generation

Inverter maximum power generation

-

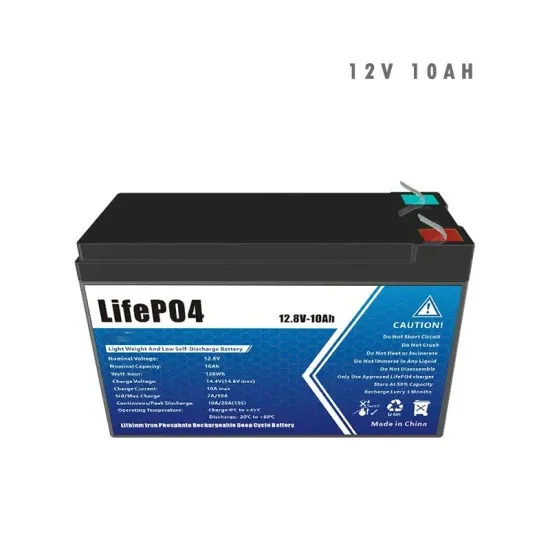

Power module 12v to 220v inverter

Power module 12v to 220v inverter

-

Inverter temperature over-temperature limit power

Inverter temperature over-temperature limit power

-

Small power home inverter

Small power home inverter

-

Photovoltaic power generation inverter and energy storage

Photovoltaic power generation inverter and energy storage

-

The photovoltaic inverter is first connected to the power supply

The photovoltaic inverter is first connected to the power supply

-

Solar water pump inverter drives power generation

Solar water pump inverter drives power generation

-

Israel photovoltaic power station inverter

Israel photovoltaic power station inverter

-

Power of Self-Contained Inverter

Power of Self-Contained Inverter

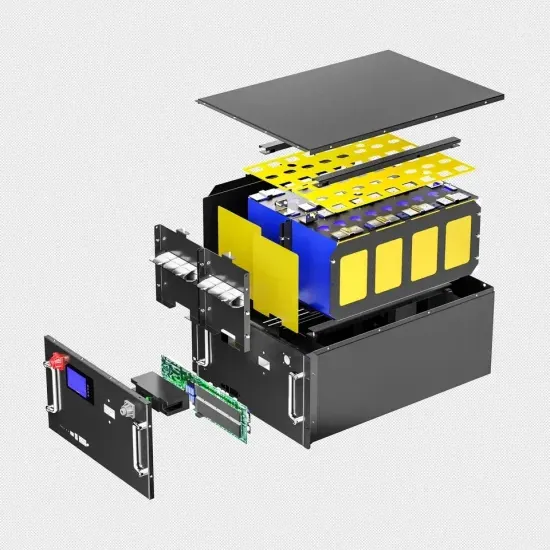

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.