Exceeding Inverter Limits

The general rule of thumb is that your inverter Max Input voltage must be greater than Voc x 1.2, otherwise the inverter will shut down (if you are very lucky) or fry (more likely).

Get a quote

Why Grid Voltage Exceeds Limits and How to Fix Inverter Issues

Summary: Solar system owners often face grid voltage limit warnings from inverters. This article explains why voltage spikes occur, their impact on renewable energy systems, and proven

Get a quote

What causes inverter overvoltage errors? – Solar Power Store

Inverter overvoltage errors occur when the DC input voltage from your solar panels exceeds the inverter''s maximum voltage rating. While your system may still operate temporarily, this can

Get a quote

Inverter: voltage limits

Navigation: Glossary > Inverter: voltage limits The inverter can perform the MPP tracking within a given voltage range, specified by VmppMin and VmppMax. When the MPP of the array is

Get a quote

Inverter Clipping: Massive Problem or Nothing to Worry About?

Clipping refers to potential solar energy loss when panel production exceeds the maximum inverter output. Outside of off-grid systems and direct DC applications, solar energy

Get a quote

How to Solve the AC Overvoltage Problem of On Grid Inverter

When the inverter detects that the grid voltage (AC voltage) exceeds the specified range, the inverter must trip and stop working, in order to ensure the equipment safety and protect the

Get a quote

Inverter will not produce because of high grid voltage

The upper limit for inverter ac voltage is typically 264v, so raised to the limit it would keep you operational with a couple volts wiggle room. That said at 130/260v you''re going to be putting a

Get a quote

AND USER MANUAL INST

LOAD" demand. The inverter delivers power to the "LOAD" terminal (essential loads panel) + excess power to the "GRID" terminal (main service panel AND grid), however it will ONLY

Get a quote

Application Note

One method used for this purpose is limiting the export power: The inverter dynamically adjusts the PV power production in order to ensure that export power to the grid does not exceed a

Get a quote

Getting over voltage message and inverters are shutting down

Rule of thumb is to have about 1.21 or higher for the power ratio, and you''ll get great performance. Some say that high DC wattage and lower AC wattage will cause clipping to occur which is

Get a quote

Inverter will not produce because of high grid voltage

The upper limit for inverter ac voltage is typically 264v, so raised to the limit it would keep you operational with a couple volts wiggle room. That said at 130/260v you''re going to be

Get a quote

Why Does My Inverter Keep Shutting Off?

If your inverter is continuously shutting down, check for one or more of the following conditions: Sufficient sunlight to power the inverters as

Get a quote

Making a Self-Powered Generator – Homemade

A free energy enthusiast from South Africa who doesn''t want to reveal his name has generously shared the details of his solid state self

Get a quote

Inverter clipping: How to maximize solar project value

Inverter clipping, or "inverter saturation," occurs when DC power from a PV array exceeds an inverter''s maximum input rating. The inverter may adjust the DC voltage to reduce

Get a quote

Inverter Clipping: Massive Problem or Nothing to

Clipping refers to potential solar energy loss when panel production exceeds the maximum inverter output. Outside of off-grid systems

Get a quote

How to avoid that solar inverters switch off at too high grid voltage

At least here, in the Netherlands, we have issues in some areas with a too high grid voltage, when there is a over production of solar power. When the standard 230V grid voltage

Get a quote

Growatt inverter limits

Can someone confirm that they are able to power loads far in excess of the inverter limits when the unit uses the grid pass-through? Or, alternatively, can it be confirmed that

Get a quote

WHY DO INVERTERS LIMIT PV INPUT VOLTAGE?

When solar panels generate electricity, their output voltage can vary depending on factors like sunlight intensity and temperature. If the input voltage to an inverter exceeds its

Get a quote

What Happens If You Overload Your Inverter? Real Dangers and

This in-depth guide breaks down the symptoms, dangers, and long-term effects of pushing your inverter too hard. Learn how to calculate load, prevent overload, and fix issues if

Get a quote

Maximum Inverter Power & Limit Grid Feed In

If battery is full, available excess power is feed into the grid although the grid setpoint is lower. To avoid triggering the fuse of a week grid

Get a quote

4. Configuration

If more power is available when those two priorities are met, then that power will be fed to the utility grid. Please note that when enabling this option, the DVCC charge current limit

Get a quote

WHY DO INVERTERS LIMIT PV INPUT VOLTAGE?

When solar panels generate electricity, their output voltage can vary depending on factors like sunlight intensity and temperature. If the input

Get a quote

voltage limiting

Is there no device that exists to limit PV voltage on those rare but most powerful of generating days, allowing me to run more panels and my inverter at max for more of the rest of

Get a quote

When choosing an inverter, what voltage ratings

Understanding these specifications will help you select an inverter that meets your solar system''s requirements and operates efficiently within safe limits.

Get a quote

6 FAQs about [Self-generating inverter voltage exceeds limit]

Can a PV inverter self-regulate?

Most inverters can self-regulate when the PV array power exceeds the maximum input, meaning it adjusts the DC voltage and reduces the current going into the inverter. So, long story short, some clipping is unlikely to impact the longevity of your equipment.

What happens if an inverter reaches a maximum output level?

Inverters are only capable of certain power output levels, which are highlighted on their datasheets. If the maximum output of the inverter has been reached but the panels are still pumping energy toward it, that extra power is lost.

What is a good AC voltage for an inverter?

The upper limit for inverter ac voltage is typically 264v, so raised to the limit it would keep you operational with a couple volts wiggle room. That said at 130/260v you’re going to be putting a strain on electronic circuits in the house. Utility really shouldn’t be running that high for any amount of time.

Do SolarEdge inverters support advanced grid limitations?

To improve grid stability, many electric utilities are introducing advanced grid limitations, requiring control of the active and reactive power of the inverter by various mechanisms. SolarEdge inverters with CPU version 2.337 and later support these requirements (some features may require later versions; refer to the relevant feature for details).

What is a control state in an inverter?

Each control state is a combination of the following three fields: AC output power limit – limits the inverter’s output power to a certain percentage of its rated power with the range of 0 to 100 (% of nominal active power). CosPhi – sets the ratio of active to reactive power.

How does a PV inverter work?

One method used for this purpose is limiting the export power: The inverter dynamically adjusts the PV power production in order to ensure that export power to the grid does not exceed a preconfigured limit. To enable this functionality, an energy meter that measures export or consumption must be installed at the site.

Guess what you want to know

-

The inverter prompts that the grid voltage exceeds the limit

The inverter prompts that the grid voltage exceeds the limit

-

Inverter AC input current exceeds limit

Inverter AC input current exceeds limit

-

Sao Tome and Principe high voltage inverter

Sao Tome and Principe high voltage inverter

-

What is the maximum voltage of a 5kw inverter

What is the maximum voltage of a 5kw inverter

-

Brunei wide voltage inverter

Brunei wide voltage inverter

-

Photovoltaic inverter voltage

Photovoltaic inverter voltage

-

Inverter adjusts voltage to 220

Inverter adjusts voltage to 220

-

Inverter intermediate DC voltage

Inverter intermediate DC voltage

-

1v input voltage inverter

1v input voltage inverter

-

How much is the inverter output voltage adjusted to

How much is the inverter output voltage adjusted to

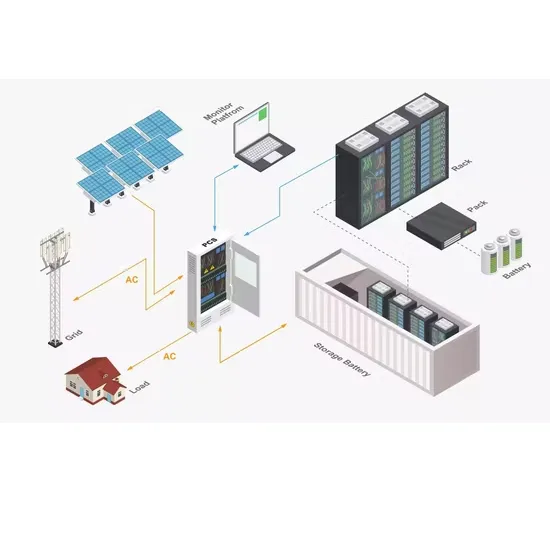

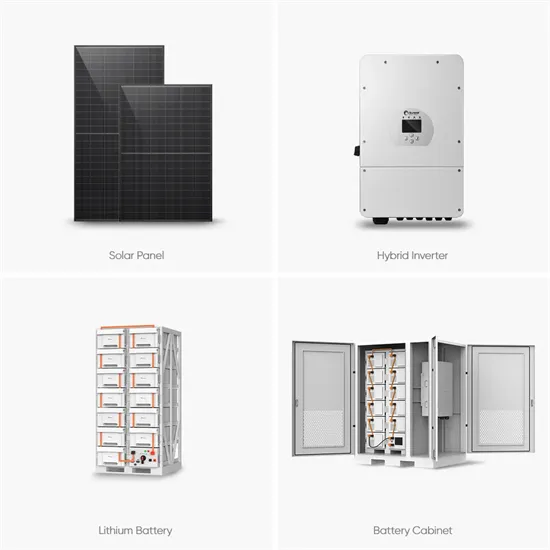

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.