Key Parameters of Solar Panel Data Sheets

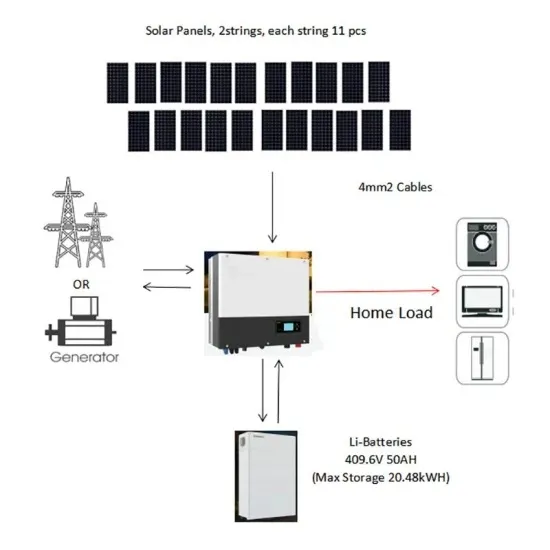

Vmp is the voltage at which the panel produces its maximum power. Importance: This value helps determine the compatibility of the panel with your inverter or battery system.

Get a quote

How-To Determing Solar String Size (Examples

Determine your solar string size by considering panel & inverter specs, temperature effects, and calculating maximum string size. Consult a

Get a quote

Understanding the Inverter Operating Voltage Temperature

The voltage temperature coefficient measures how much an inverter''s output voltage changes per degree Celsius (°C) of temperature fluctuation. For example, a coefficient of -0.3%/°C means

Get a quote

How does ambient temperature affect the output to a standard

There is a voltage temperature coefficient for every module on the spec sticker on back. This represents the change in voltage output for degrees difference above or below the standard

Get a quote

Voc VS Vmp in string sizing, temperature coefficient and 690.7

His position is that the open circuit voltage should not be relevant, because there is no current in that state, and if we keep our temperature corrected Vmp below the inverter max

Get a quote

A comparative study of stability of switching voltage of CMOS inverters

The classic CMOS Schmitt inverter exhibits incredible thermal stability of switching voltage over wide operating temperatures ranging from −20 to 120 °C with approximately zero

Get a quote

Stringing PV inverter | AE 868: Commercial Solar Electric Systems

The NOCT and % temperature coefficients from the modules datasheet can be used to determine the min and max voltage levels and the range of MPP corresponding to it.

Get a quote

Voc and Vmp Calculations in Inverter Tool Tab –

This formula applies a temperature coefficient specific to each panel to adjust the Voc and Vmp values from their standard test conditions (STC, 25°C), to any

Get a quote

What is the temperature coefficient of solar panels

During summer, temperatures can reach or even exceed 60 or 70 °C. The average operating temperature is about 50 °C, meaning 25 °C more than the

Get a quote

How to Calculate a PV Module''s Voltage (Voc) for

When designing a system, it is important to use the PV module''s Temperature Coefficient to calculate the gains (or losses) in voltage due to local ambient

Get a quote

Solar Panel Operating Temperature: Complete Guide 2025

Learn how temperature affects solar panel efficiency, optimal operating ranges, and strategies to maximize performance in any climate. Expert guide with real data.

Get a quote

Photonik | String Voltage Calculator

The amount of voltage (Voc) change is calculated based on the ambient temperature and the solar panel''s "Temperature coefficient of Voc", which is the voltage difference for every degree

Get a quote

Temperature Coefficient of a Photovoltaic Cell

Estimating the temperature variation in which a pv panel, module or array operates, helps to determine the temperature-adjusted voltages from the panel. The exact temperature

Get a quote

How to Calculate PV String Size — Mayfield Renewables

How to manually calculate PV string size for photovoltaic systems based on module, inverter, and site data. Design code-compliant PV systems and follow design best

Get a quote

Thermal Study of Inverter Components: Preprint

Thermal histories of inverter components were collected from operating inverters from several manufacturers and three locations. The data were analyzed to determine thermal profiles, the

Get a quote

Solar Panel Efficiency vs. Temperature (2025) | 8MSolar

When discussing solar panel efficiency and temperature, one crucial term to understand is the "temperature coefficient." This metric quantifies how much a panel''s power

Get a quote

PVmodule

However this is important during the sizing phase, as this determines the array voltage at low temperature, which should not exceed the absolute maximum voltage of the inverter input or

Get a quote

How to read these inverter specs : r/SolarDIY

The temperature coefficients will cause the voltage and current to vary with temperature, but starting with your base calculations and considering the maximum and minimum operating

Get a quote

Understanding the Inverter Operating Voltage Temperature Coefficient

The voltage temperature coefficient measures how much an inverter''s output voltage changes per degree Celsius (°C) of temperature fluctuation. For example, a coefficient of -0.3%/°C means

Get a quote

Voc and Vmp Calculations in Inverter Tool Tab – OpenSolar

This formula applies a temperature coefficient specific to each panel to adjust the Voc and Vmp values from their standard test conditions (STC, 25°C), to any given temperature.

Get a quote

Maximum open circuit voltage calculator

Starting values. Total string voltage (Rated Voc times number of panels in series) The worst case cold temperature in c. The panels temperature coefficient in %/C Temperature

Get a quote

Technical notes on output rating, operating temperature and

Inverters: When the power semiconductors and / or transformers reach a pre-set temperature, inverters will first show a temperature pre-warning, and if temperature increases further, the

Get a quote

Solar Inverter String Design Calculations

The voltage/current that solar panels work at is dependent on the cell temperature, the higher the temperature the lower the voltage / current the solar panel will produce, and vice versa.

Get a quote

Voc VS Vmp in string sizing, temperature coefficient and 690.7

Compared to the crude tools we use today, simulations use 20-year datasets that account for temperature and irradiance and model performance based on some 30 different

Get a quote

How to Calculate a PV Module''s Voltage (Voc) for Different

When designing a system, it is important to use the PV module''s Temperature Coefficient to calculate the gains (or losses) in voltage due to local ambient temperature changes. This will

Get a quote

6 FAQs about [Inverter operating voltage temperature coefficient]

Why is temperature coefficient important in solar panel sizing?

During the sizing, the temperature coefficient is an important factor. 1. Solar panel temperature coefficient of Voc/ Isc: The voltage/current that solar panels work at is dependent on the cell temperature, the higher the temperature the lower the voltage / current the solar panel will produce, and vice versa.

What temperature do inverters rated at?

In our datasheets inverters, and the inverter function of Multis and Quattros, are rated at 25oC (75oF). On average, derating at higher temperatures is as shown below (see paragraph 4 for the theoretical background). Low temp. High temp. 2. Battery chargers: continuous output rating as a function of temperature

What does a temperature coefficient of 0.25% mean?

For example, a Temperature Coefficient of 0.25% per o C means that for every 1 o C change in temperature, the voltage, current or power output of the panel will change by one-quarter of one percent. Thus for every 1 o C temperature change above 25 o C (hotter), the pv panel temporarily loses 0.25% of its voltage.

What is the temperature coefficient of a PV panel?

But more interestingly it also tells us that the temperature coefficient of the pv panel is: -0.30% per o C of V OC.

What is the operating voltage range for a string inverter?

The MPPT operating voltage range for most string inverters is between 80V and 600V, depending on the inverter make and model. The voltage range for Solar MPPT charge controllers is generally much lower and varies from 24V up to 250V. However, several high-voltage models are available which operate up to 600V.

How do I know if a PV module is compatible with voltage specs?

This will ensure the PV module is compatible with the system's voltage specs. The common practice is to compare the PV module's Temperature Coefficient against the lowest recorded temperature for the area. However, solar designers have realized that using 100-year record-low temperatures result in overly conservative designs.

Guess what you want to know

-

String inverter operating voltage

String inverter operating voltage

-

36v inverter What is the minimum operating voltage

36v inverter What is the minimum operating voltage

-

What is the operating voltage of a 12v inverter

What is the operating voltage of a 12v inverter

-

Inverter voltage ac

Inverter voltage ac

-

What voltage does the inverter change

What voltage does the inverter change

-

Middle East low voltage inverter manufacturer

Middle East low voltage inverter manufacturer

-

Will there be voltage when the inverter is stopped

Will there be voltage when the inverter is stopped

-

Eastern European low voltage inverter factory direct sales

Eastern European low voltage inverter factory direct sales

-

Battery voltage reduction to inverter

Battery voltage reduction to inverter

-

Can the voltage of the photovoltaic inverter be adjusted

Can the voltage of the photovoltaic inverter be adjusted

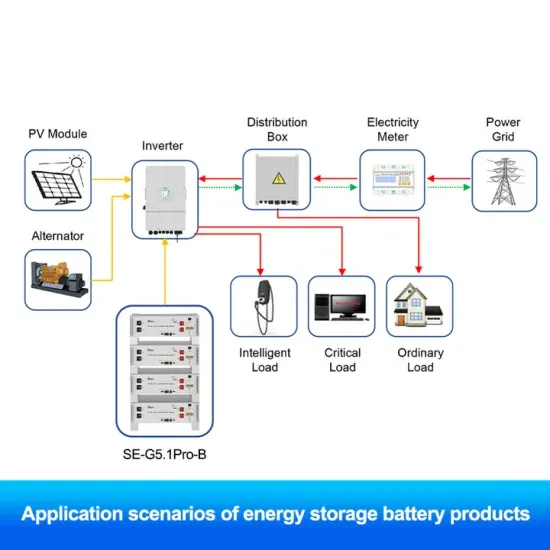

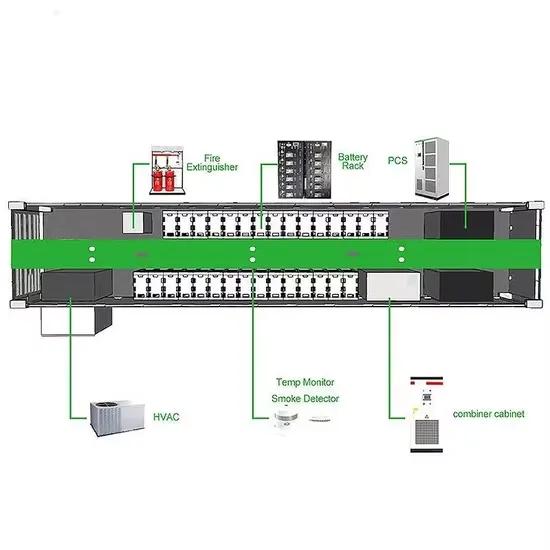

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

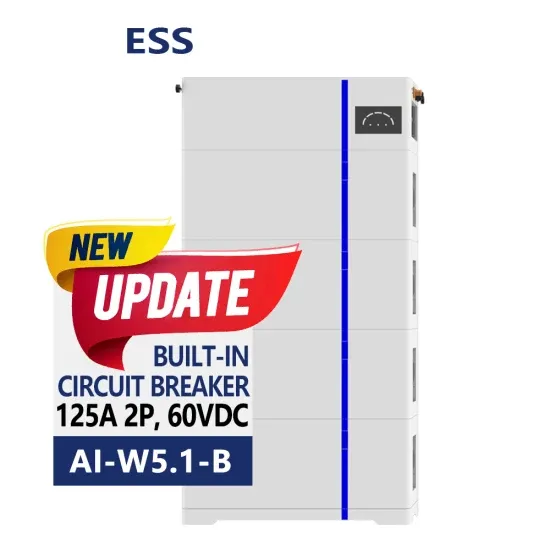

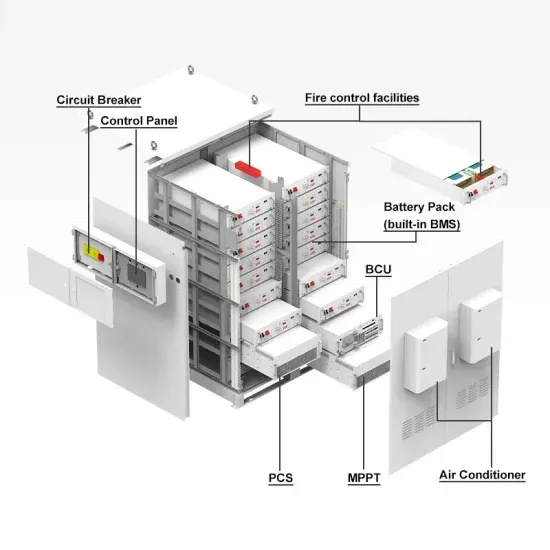

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.