Strings, Parallel Cells, and Parallel Strings

Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost

Get a quote

Battery configurations (series and parallel) and their protections

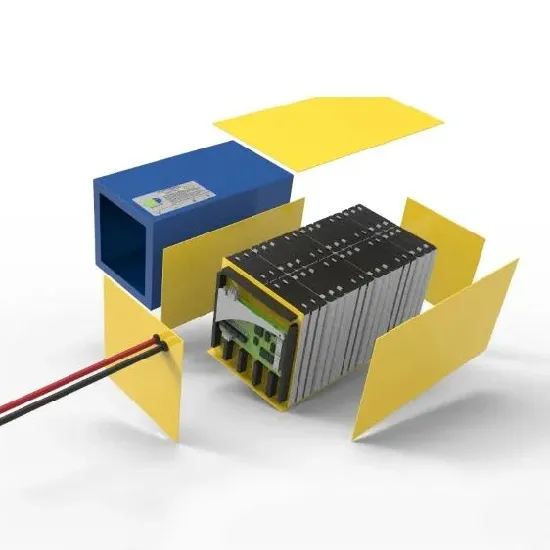

To achieve the desired voltage, the cells are connected in series to add to the voltage of the cells. The cells are connected in parallel to reach the desired capacity by adding

Get a quote

Everything About Lithium Battery Series & Parallel

Learn how to safely connect lithium batteries in series and parallel. Avoid risks, extend battery life and build reliable power systems with

Get a quote

How to Calculate the Number of Lithium Batteries in Series and in Parallel?

We all know that the series voltage of lithium batteries increases and the parallel capacity increases. So how to calculate how many series and how many batteries a lithium battery

Get a quote

How to Connect Lithium Batteries in Series and Parallel?

A series-parallel connection combines both configurations to increase both voltage and capacity. For example, connecting four 3.7V 100mAh lithium cells in a series-parallel

Get a quote

Cells in Series and Parallel – NPP POWER

Increase voltage in series: 3.7V single cells can be assembled into battery packs of 3.7* (N)V (N: number of single cells) such as 7.4V, 12V, 24V, 36V, 48V, 60V, 72V, etc. as

Get a quote

BU-302: Series and Parallel Battery Configurations

Read about serial and parallel battery configurations. Connecting battery cells gains higher voltages or achieves improved current loading.

Get a quote

Understanding Battery Pack Configurations: Series vs. Parallel

Battery pack configurations determine how much power a battery can provide and for how long. Whether you''re choosing a battery pack for an electric vehicle, a robotics project,

Get a quote

Impact of Individual Cell Parameter Difference on the

Lithium-ion power batteries are used in groups of series–parallel configurations. There are Ohmic resistance discrepancies, capacity

Get a quote

Series and Parallel, which is the first when assembling

Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them

Get a quote

Battery Packs In Series Or Parallel: Key Differences And Wiring

Series connections require connecting the positive terminal of one battery to the negative terminal of the next, while parallel connections connect all positive terminals together

Get a quote

Definition of Series and Parallel Connection of Lithium Batteries

Lithium batteries connected in series Add the voltage of batteries, capacity remains the same, and internal resistance increases. Lithium batteries connected in paralle Constant

Get a quote

BU-302: Series and Parallel Battery Configurations

We all know that the series voltage of lithium batteries increases and the parallel capacity increases. So how to calculate how many series and how many

Get a quote

Lithium Battery Pack

Let''s assume I am going to build a Li-ion battery pack with 12 18650s, where I connect four cells together in parallel and then the three sets of four in series. My understanding is that a BMS

Get a quote

Series and Parallel Configuration of Lithium Battery

Using the series and parallel configuration, you can design the more voltage and higher capacity battery pack with a standard cell size.

Get a quote

Handbook On Lithium Battery Pack Design

The environment in which the battery pack is used and the electrical connection of the individual cells (series or parallel) are two key considerations when designing a battery pack and working

Get a quote

Series Parallel Battery Pack Modules Trend in 2024

As the world becomes more dependent on technology powered by lithium-ion batteries, the demand for more efficient and powerful battery packs

Get a quote

Lithium Battery Pack

Let''s assume I am going to build a Li-ion battery pack with 12 18650s, where I connect four cells together in parallel and then the three sets of four in series.

Get a quote

How to Calculate Lithium-Ion Battery Pack Capacity

In an 18650 battery pack design, the cells are typically connected in series and parallel configurations. Connecting cells in series increases the

Get a quote

Battery configurations (series and parallel) and their

To achieve the desired voltage, the cells are connected in series to add to the voltage of the cells. The cells are connected in parallel to reach the

Get a quote

Everything About Lithium Battery Series & Parallel

Learn how to safely connect lithium batteries in series and parallel. Avoid risks, extend battery life and build reliable power systems with our expert guide.

Get a quote

Optimal fast charging strategy for series-parallel configured lithium

First, an improved electric-thermal-aging coupled model is established for a 3-parallel 6-series connected commercial battery pack. The model can estimate the anode

Get a quote

DIY 3S1P LiPo Battery Pack

DIY 3S1P LiPo Battery Pack: Today, I''ll be putting together 3 lithium polymer battery cells to make a 3S1P (3 series 1 parallel) battery pack that can be used with RC equipment and I''ll be using

Get a quote

Cells in Series and Parallel – NPP POWER

Increase voltage in series: 3.7V single cells can be assembled into battery packs of 3.7* (N)V (N: number of single cells) such as 7.4V, 12V, 24V,

Get a quote

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Get a quote

Guess what you want to know

-

3 series 1 parallel lithium battery pack

3 series 1 parallel lithium battery pack

-

6 series 4 parallel 24v lithium battery pack

6 series 4 parallel 24v lithium battery pack

-

60v 40ah lithium battery pack series and parallel connection

60v 40ah lithium battery pack series and parallel connection

-

Is the lithium battery pack connected in series or in parallel

Is the lithium battery pack connected in series or in parallel

-

25a series lithium battery pack

25a series lithium battery pack

-

Lithium battery pack parallel discharge

Lithium battery pack parallel discharge

-

4 series 7 lithium battery pack

4 series 7 lithium battery pack

-

Lithium battery packs in series and parallel

Lithium battery packs in series and parallel

-

North Asia lithium battery pack supplier

North Asia lithium battery pack supplier

-

Lithium battery pack low temperature

Lithium battery pack low temperature

Industrial & Commercial Energy Storage Market Growth

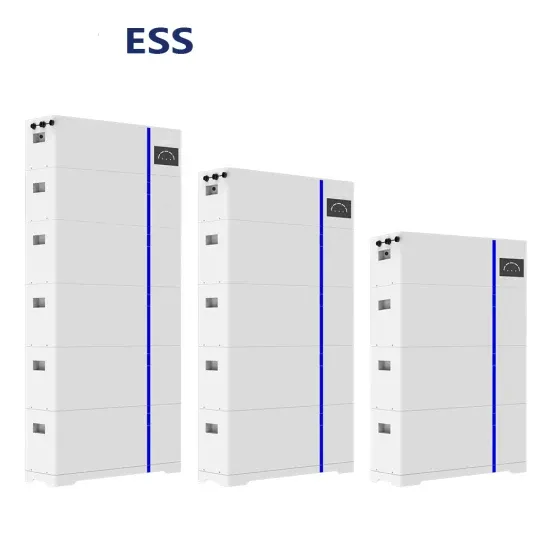

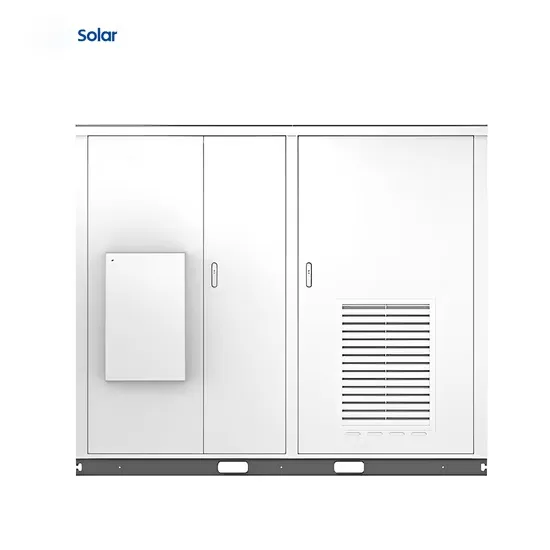

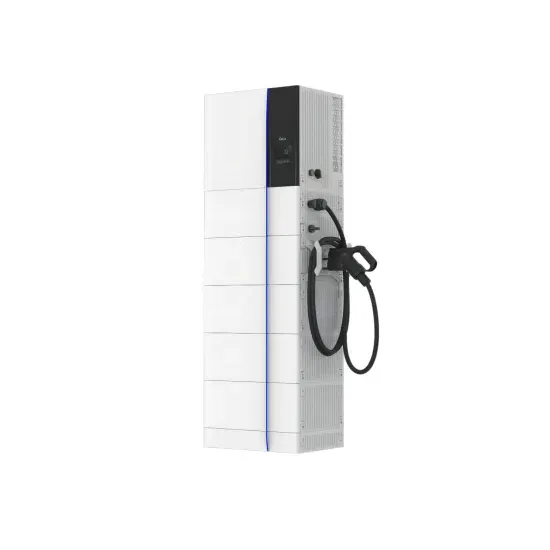

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.