Ultimate Guide of LiFePO4 Lithium Batteries in Series & Parallel

Unlock the ultimate guide to using LiFePO4 lithium batteries in series and parallel. Learn configurations, benefits, and tips for optimal performance!

Get a quote

Impact of Individual Cell Parameter Difference on the

Lithium-ion power batteries are used in groups of series–parallel configurations. There are Ohmic resistance discrepancies, capacity

Get a quote

How To Wire Lithium Batteries In Parallel Increase

In this article, we will explain why you would want to wire lithium-ion batteries in parallel, how you wire them in series and how to charge battery

Get a quote

Everything About Lithium Battery Series & Parallel

Series connection is the most common method to make the battery pack reach the required operating voltage. Series connection is the

Get a quote

Lithium Series, Parallel and Series and Parallel

Connecting batteries in series or parallel could be the solution. But when you''re trying to decide to connect your batteries in series vs. parallel, which is better?

Get a quote

EV battery : serie vs. parallel cells and modules

Challenges in setups with parallel cells / modules and packs in EV conversions. Do''s and don''ts for more battery capacity (kWh) explained. Don''t overcharge.

Get a quote

Lithium Battery Series & Parallel Operation | Fact Sheets

Battery packs are designed by connecting multiple cells in series; each cell adds its voltage to the battery''s terminal voltage. Figure 1 below shows a typical EarthX 13.2V LiFePO4 starter

Get a quote

3. Battery bank wiring

The maximum is at around 3 (or 4) paralleled strings. The reason for this is that with a large battery bank like this, it becomes tricky to create a balanced battery bank. In a large

Get a quote

Can You Mix Different Capacity Lithium Batteries?

Schematic for multiple lithium batteries in parallel Here is a diagram for multiple lithium batteries in parallel. You can add individual battery

Get a quote

Lithium-Ion Batteries: Series vs. Parallel—What''s the Difference?

When setting up a battery system, especially with lithium batteries, you often face a choice between connecting them in series or in parallel. Each configuration has its unique benefits

Get a quote

Batteries in Series vs Parallel: Which is Better?

Connecting batteries in series or parallel could be the solution. But when you''re trying to decide to connect your batteries in series vs. parallel, which is better? Both methods increase total

Get a quote

Is it better to connect lithium batteries in series or parallel?

Use series for high-voltage devices like EVs; choose parallel for extended runtime in low-voltage systems. Critical factors include cell matching and battery management systems

Get a quote

A deep analysis of lithium battery in series and parallel

In lithium battery applications, both battery in series and parallel connections have their advantages and disadvantages. Series connections are suitable for

Get a quote

Battery Series vs Parallel Explained

Key Considerations When Choosing Batteries Chemistry compatibility: Never mix lithium and lead-acid batteries in the same bank. Capacity matching: For parallel connections,

Get a quote

Lithium battery series and parallel, the difference between battery

Lithium battery series and parallel: Both parallel combination and series combinations are in the middle of the battery pack, increasing the voltage and capacity.

Get a quote

Everything About Lithium Battery Series & Parallel

Series connection is the most common method to make the battery pack reach the required operating voltage. Series connection is the best choice when you need more voltage

Get a quote

Helpful Guide to Lithium Batteries in Parallel and Series

Understand how to connect lithium batteries in parallel and series. Get practical tips and avoid common pitfalls. Start optimizing your battery

Get a quote

Series and Parallel, which is the first when assembling lithium battery

Series and Parallel, which is the first when assembling lithium battery packs? In the design of the battery modules, whether to connect them in series first and then in parallel

Get a quote

Battery Packs In Series Or Parallel: Key Differences And Wiring

When choosing between series and parallel configurations for battery packs, consider voltage requirements, current capacity, space considerations, and applications.

Get a quote

Lithium Series, Parallel and Series and Parallel

Connecting multiple lithium batteries into a string of batteries allows us to build a battery bank with the potential to operate at an increased voltage, or with increased capacity and runtime, or both.

Get a quote

Series vs Parallel Battery Wiring: Key Differences,

When using multiple batteries in a project, you have two primary wiring configurations—series and parallel. Each has distinct advantages

Get a quote

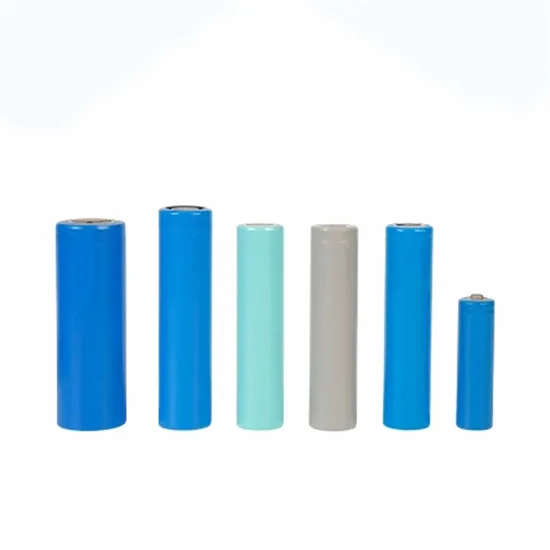

Lithium Battery Pack

Let''s assume I am going to build a Li-ion battery pack with 12 18650s, where I connect four cells together in parallel and then the three sets of four in series.

Get a quote

Helpful Guide to Lithium Batteries in Parallel and Series

Understand how to connect lithium batteries in parallel and series. Get practical tips and avoid common pitfalls. Start optimizing your battery setup today!

Get a quote

Battery Packs In Series Or Parallel: Key Differences And Wiring

Connecting battery packs in series increases the output voltage while keeping the capacity the same. In contrast, wiring them in parallel boosts the total capacity without

Get a quote

Guess what you want to know

-

4 parallel 10 series lithium battery pack

4 parallel 10 series lithium battery pack

-

Connect two lithium battery packs in parallel

Connect two lithium battery packs in parallel

-

Is the lithium battery pack connected in series or in parallel

Is the lithium battery pack connected in series or in parallel

-

3 series 1 parallel lithium battery pack

3 series 1 parallel lithium battery pack

-

Can lithium battery packs be used in parallel

Can lithium battery packs be used in parallel

-

Can the three lithium battery packs in Vatican be used in parallel

Can the three lithium battery packs in Vatican be used in parallel

-

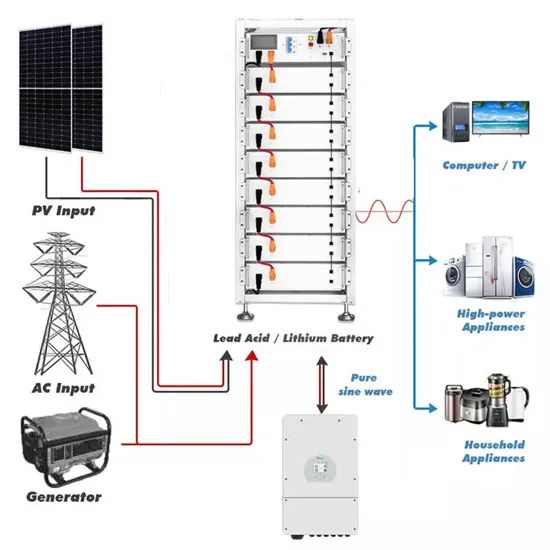

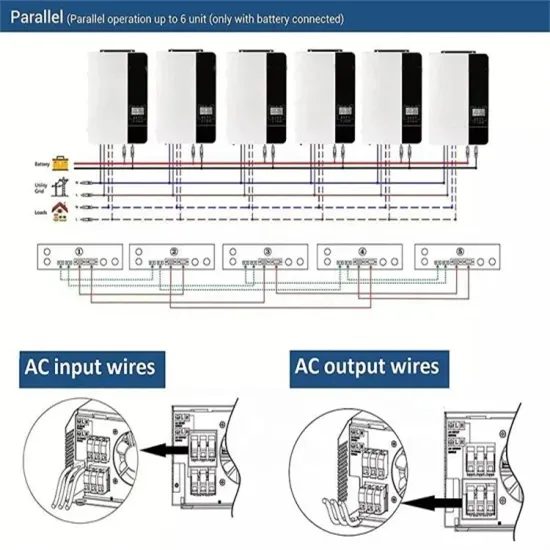

How many inverters are needed for lithium battery packs

How many inverters are needed for lithium battery packs

-

How many lithium iron phosphate battery packs are needed for 60v

How many lithium iron phosphate battery packs are needed for 60v

-

One of the lithium battery packs is full

One of the lithium battery packs is full

-

Enterprises capable of producing lithium battery packs

Enterprises capable of producing lithium battery packs

Industrial & Commercial Energy Storage Market Growth

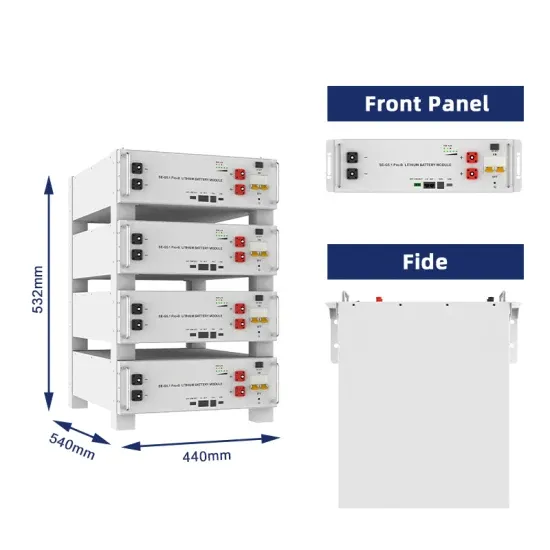

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.