How to Balance Lithium Batteries in Parallel

Balancing lithium batteries in parallel involves measuring each battery''s voltage before connection, ensuring they''re within an acceptable range of each other, and then

Get a quote

Multi-battery Packs | Li-Ion & LiPoly Batteries | Adafruit Learning

Not only should you not do this with alkaline batteries, but its especially dangerous with lithium batteries. One battery can discharge into another, damaging it or causing a fire! If

Get a quote

Consistency evaluation of Lithium-ion battery packs in electric

The battery pack inconsistency is affected by factors such as battery capacity, internal resistance, and self-discharge rate during use, resulting in differences in aging and

Get a quote

Performance Imbalances in Parallel-Connected Cells

Addressing performance imbalances in parallel-connected cells is crucial in the rapidly developing area of lithium-ion battery technology.

Get a quote

What Should Be Noted When Connecting Two Battery Packs In

This video focuses on the key precautions for connecting two lithium battery packs in parallel, especially how to ensure consistent charging and discharging currents. We

Get a quote

What Should Be Noted When Connecting Two Battery Packs In Parallel

This video focuses on the key precautions for connecting two lithium battery packs in parallel, especially how to ensure consistent charging and discharging currents. We

Get a quote

Can you safely wire lithium-ion cells in parallel and charge and

For the first part of your question, yes. In a 2/3/4P lithium ion pack, cells are wired in parallel. In this configuration, they are self balancing without any circuitry. The cells don''t even have to be

Get a quote

Strings, Parallel Cells, and Parallel Strings

Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost

Get a quote

Management of imbalances in parallel-connected lithium-ion battery packs

This paper investigated the management of imbalances in parallel-connected lithium-ion battery packs based on the dependence of current distribution on cell chemistries,

Get a quote

How to Balance Lithium Batteries with Parallel BMS?

However, parallel batteries also face many challenges, especially in balancing the state of charge and ensuring the life of the battery pack. In this

Get a quote

Why Are My Parallel Batteries Not Discharging Equal?

Beyond the design temperature of the battery, the capacity and discharge of the battery changes, and the parallel battery discharge will be inconsistent. When encountering

Get a quote

How to Connect Two Batteries in Parallel?

Learn how to connect two batteries in parallel, increase capacity, and avoid common mistakes. Perfect for DIY enthusiasts and tech lovers. Get

Get a quote

Why Are My Parallel Batteries Not Discharging Equally?

Is It Better To Charge Batteries In Series Or Parallel? Parallel battery configuration helps increase the duration in which batteries can power equipment, but due to the increased amp-hour

Get a quote

Impact of Individual Cell Parameter Difference on the

To address the issue of accelerated aging of aging individual cells caused by a parameter difference in series–parallel battery packs, the voltage change

Get a quote

Impact of Individual Cell Parameter Difference on the

Lithium-ion power batteries are used in groups of series–parallel configurations. There are Ohmic resistance discrepancies, capacity

Get a quote

Performance Imbalances in Parallel-Connected Cells

Addressing performance imbalances in parallel-connected cells is crucial in the rapidly developing area of lithium-ion battery technology.

Get a quote

Energy Technology

This work aims to make a comparative analysis of the unbalanced discharging phenomenon for battery packs with series/parallel configurations due to the temperature

Get a quote

Lithium Battery Series & Parallel Operation | Fact Sheets

Check out our fact information sheet on the Lithium Battery Series and Parallel Operation. Get a breakdown of the basics, BMS, Parallel Operation and more!

Get a quote

Discharge Capacity Estimation for Lithium–Ion Battery

For lithium-ion battery packs with cells connected in parallel, a method is provided herein to predict the discharge current of the cells. Based on this method, an

Get a quote

switches

I''m interested in building lithium ion battery packs, and I was wondering if there is a way to change the pack on the fly from series to parallel - basically to allow charging in parallel

Get a quote

How to Connect Lithium Batteries in Parallel?

When connecting lithium batteries in parallel, pay attention to battery consistency and avoid mixing batteries of different brands, capacities, or new or old batteries. When lithium

Get a quote

Impact of Individual Cell Parameter Difference on the

To address the issue of accelerated aging of aging individual cells caused by a parameter difference in series–parallel battery packs, the voltage change curve at the end of charge and

Get a quote

Can you safely wire lithium-ion cells in parallel and charge and

For the first part of your question, yes. In a 2/3/4P lithium ion pack, cells are wired in parallel. In this configuration, they are self balancing without any circuitry. The cells don''t even

Get a quote

Battery configurations (series and parallel) and their

The cells are connected in parallel to reach the desired capacity by adding ampere-hour (Ah) to reach the desired capacity. This combination of

Get a quote

2 identical batteries in parallel, but unequal discharge?

Bank = any two or more complete battery packs working in concert connected to a Common Bus. Pack = 1 completed battery assembly with BMS, Fuse - if used independently

Get a quote

How to Balance Lithium Batteries with Parallel BMS?

However, parallel batteries also face many challenges, especially in balancing the state of charge and ensuring the life of the battery pack. In this article, we will dig into

Get a quote

Connecting batteries in parallel – BatteryGuy Knowledge Base

If you connect rechargeable batteries in parallel and one is discharged while the others are charged – the charged batteries will attempt to charge the discharged battery.

Get a quote

6 FAQs about [Lithium battery pack parallel discharge]

How to balance lithium batteries in parallel?

Balancing lithium batteries in parallel involves measuring each battery's voltage before connection, ensuring they're within an acceptable range of each other, and then connecting all positive and negative terminals together. What Does It Mean For Lithium Batteries To Be Balanced?

What is balancing lithium battery packs?

Balancing lithium battery packs, like individual cells, involves ensuring that all batteries within a system maintain the same state of charge. This process is essential when multiple battery packs are used together in series or parallel configurations.

Are lithium-ion power batteries used in series–parallel configurations?

1. Introduction 2. Establishment and Verification of Battery Pack Model 3. Influence of Individual Cell Parameter Difference on Battery Pack Performance 4. Conclusions Lithium-ion power batteries are used in groups of series–parallel configurations.

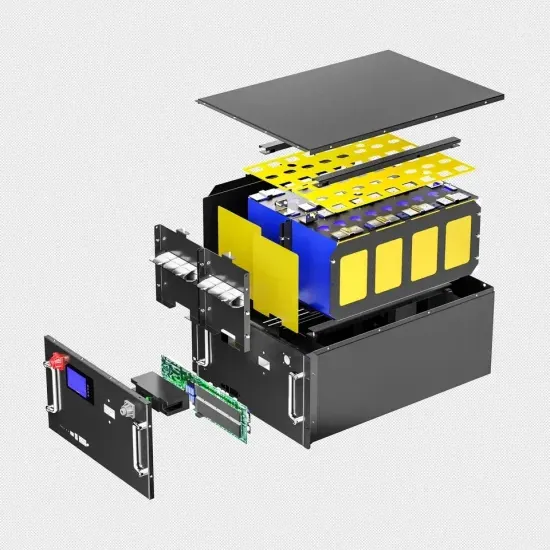

What is a parallel lithium battery pack?

According to the parallel principle, the current of the main circuit is equal to the sum of the currents of the parallel branches. Therefore, a parallel lithium battery pack with “n” parallel batteries achieves the same charging efficiency as a single battery, with the charging current being the sum of the individual battery currents.

What happens if you connect two lithium batteries in parallel?

By connecting two or more lithium batteries with the same voltage in parallel, the resulting battery pack retains the same nominal voltage but boasts a higher Ah capacity. For example, connecting two 12V 10Ah batteries in parallel method creates a 12V 20Ah battery.

Why do lithium ion batteries need to be connected in series?

To meet the power and energy requirements of the specific applications, lithium-ion battery cells often need to be connected in series to boost voltage and in parallel to add capacity . However, as cell performance varies from one to another [2, 3], imbalances occur in both series and parallel connections.

Guess what you want to know

-

Is the lithium battery pack connected in series or in parallel

Is the lithium battery pack connected in series or in parallel

-

3 series 1 parallel lithium battery pack

3 series 1 parallel lithium battery pack

-

3 7v parallel lithium battery pack

3 7v parallel lithium battery pack

-

10 series and two parallel lithium battery pack

10 series and two parallel lithium battery pack

-

Normal discharge of lithium battery pack

Normal discharge of lithium battery pack

-

6 series 4 parallel 24v lithium battery pack

6 series 4 parallel 24v lithium battery pack

-

Central African Republic lithium battery pack supplier wholesale

Central African Republic lithium battery pack supplier wholesale

-

Huijue Iraq lithium battery pack 12v

Huijue Iraq lithium battery pack 12v

-

Lithium battery pack flat pressure

Lithium battery pack flat pressure

-

Croatian high rate lithium battery pack

Croatian high rate lithium battery pack

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.