Learn About the Different Types of Battery Packaging

Discover different battery packaging types, safety rules, and how proper packaging impacts performance. Learn about lithium, solar, car battery

Get a quote

Lithium-ion battery PACK explanation

Lithium-ion battery PACK, also known as battery module, is a lithium-ion battery manufacturing process, which refers to connecting multiple lithium-ion single cell groups in

Get a quote

Understanding Lithium Ion Battery Packs: Types, Uses, and

Lithium ion battery packs are integral to modern technology and sustainable energy solutions. By understanding the different types, their uses, and adhering to safety

Get a quote

19 Battery Pack Manufacturers in 2025

This section provides an overview for battery packs as well as their applications and principles. Also, please take a look at the list of 19 battery pack

Get a quote

Expion360 I Premium Lithium Batteries to Power the

Lithium battery technology has come a long way in the last decade—Expion360 is taking it further. Our best-in-class batteries are designed and engineered in

Get a quote

Does modifying a lithium battery pack mean that the boat loses

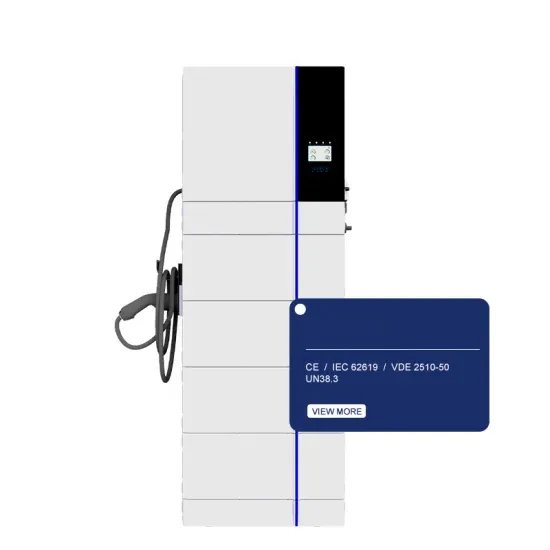

_ The increasing use of lithium batteries on board raises technical and regulatory issues. A European directive could impose a new reading of CE conformity for modified

Get a quote

Advanced Lithium Battery Manufacturing Capabilities

At Lithium Battery Company, we specialize in advanced battery pack assembly for OEMs and energy innovators. Our U.S.-based facility delivers scalable, automation-first solutions across

Get a quote

Batteries-BYD

Batteries BYD is the world''s leading producer of rechargeable batteries: NiMH batteries, Lithium-ion batteries and NCM batteries. BYD owns the complete supply chain layout from mineral

Get a quote

Battery Pack Certifications – Costs, Timelines and Key Standards

The result: a faster path to market, reduced costs, and total confidence in your product''s compliance. Lithium battery safety is at the top of the list for anyone who manufactures custom

Get a quote

Lithium iron phosphate battery

4 battery) or LFP battery (lithium ferrophosphate) is a type of lithium-ion battery using lithium iron phosphate (LiFePO 4) as the cathode material, and a

Get a quote

Battery Cell, Module or Pack. What''s the difference? [Infographics]

The manufacturing of battery cells compared to battery packs or modules are two very different industrial processes. Battery cell production is primarily a chemical process,

Get a quote

Top 100 Lithium-Ion Battery Pack Manufacturers in 2025 | ensun

Lithium Battery Company is a leading manufacturer of custom lithium-ion battery packs, specializing in high-performance solutions for commercial and industrial applications.

Get a quote

Top 5 Li Ion Battery Pack Manufacturers in 2025

Explore the top 5 li ion battery pack manufacturers in 2025. Knowing battery key features, company overview, and experiences before choosing the right solution.

Get a quote

What to Know About Lithium Battery Packs: Key Insights

Discover essential insights about lithium battery packs, including their benefits, applications, and safety tips. Learn more in this comprehensive

Get a quote

What to Know About Lithium Battery Packs: Key Insights

Discover essential insights about lithium battery packs, including their benefits, applications, and safety tips. Learn more in this comprehensive guide.

Get a quote

Battery Cell, Module or Pack. What''s the difference?

The manufacturing of battery cells compared to battery packs or modules are two very different industrial processes. Battery cell production is

Get a quote

19 Battery Pack Manufacturers in 2025

This section provides an overview for battery packs as well as their applications and principles. Also, please take a look at the list of 19 battery pack manufacturers and their company rankings.

Get a quote

Lithium Battery Packs | BigBattery | Your Source for

"Big Battery made converting our 48v lead acid EZGO cart to lithium a breeze. Our cart is lighter, faster and the range went up dramatically using just a single

Get a quote

What is a Battery Pack? Definition, Types, Applications, and

A lithium-ion battery pack is a collection of multiple lithium-ion cells connected together to store and provide electrical energy. These battery packs power various electronic

Get a quote

What Are Lithium-Ion Battery Pack Systems and How Do They Work

Lithium-ion battery pack systems are rechargeable energy storage units that power devices from smartphones to electric vehicles. They operate by moving lithium ions between

Get a quote

Wholesale Lithium ion battery packs suppliers

20 years Lithium battery pack manufacturer,battery pack designer and wholesale! 24 hours online to provide you with customized lithium battery packs solutions.

Get a quote

19 Battery Pack Manufacturers in 2025

19 Battery Pack Manufacturers in 2025 This section provides an overview for battery packs as well as their applications and principles. Also, please take a

Get a quote

All You Need to Know About Li-ion Batteries

Li-ion Battery Chemistry and working As the name obviously indicates, the Lithium Ion batteries use the Lithium ions to get the job done.

Get a quote

6 FAQs about [Pack lithium battery company mean ]

What is a lithium-ion battery pack?

A lithium-ion battery pack is a collection of multiple lithium-ion cells connected together to store and provide electrical energy. These battery packs power various electronic devices, from smartphones to electric vehicles, due to their high energy density and rechargeable nature.

What is the difference between battery pack and battery cell?

Battery Cell, Module or Pack. What's the difference? [Infographics] The manufacturing of battery cells compared to battery packs or modules are two very different industrial processes. Battery cell production is primarily a chemical process, while module and pack production is a mechanical assembly process.

What is a battery pack?

Finally, the battery pack is the complete enclosure that delivers power to the electric vehicle. The pack usually contains battery cells and/or modules, software (BMS - battery management system) and often a cooling and heating system, depending on where and how the battery pack is to be used.

What is the difference between battery cell production and module & pack production?

Battery cell production is primarily a chemical process, while module and pack production is a mechanical assembly process. Batteries are sometimes called Cells, Modules or Packs. But what does that mean? What is the difference? Battery cells are containers that chemically store energy.

What are the technical terms associated with battery packs?

Technical terms associated with battery packs include “capacity,” which refers to the total amount of energy a battery can store, usually measured in ampere-hours (Ah), and “voltage,” the electric potential difference measured in volts (V).

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

Guess what you want to know

-

Tuvalu pack lithium battery company

Tuvalu pack lithium battery company

-

Cambodia lithium battery pack supplier company

Cambodia lithium battery pack supplier company

-

Middle East lithium battery pack supplier company

Middle East lithium battery pack supplier company

-

2GWh lithium iron phosphate battery pack beneficiary company

2GWh lithium iron phosphate battery pack beneficiary company

-

Azerbaijan lithium battery pack OEM company

Azerbaijan lithium battery pack OEM company

-

Pack lithium battery mean

Pack lithium battery mean

-

The last cell of the lithium battery pack

The last cell of the lithium battery pack

-

Moldova 72v 150ah lithium battery pack

Moldova 72v 150ah lithium battery pack

-

Manufacturing 12v lithium battery pack

Manufacturing 12v lithium battery pack

-

Assembling the air-cooled lithium battery pack

Assembling the air-cooled lithium battery pack

Industrial & Commercial Energy Storage Market Growth

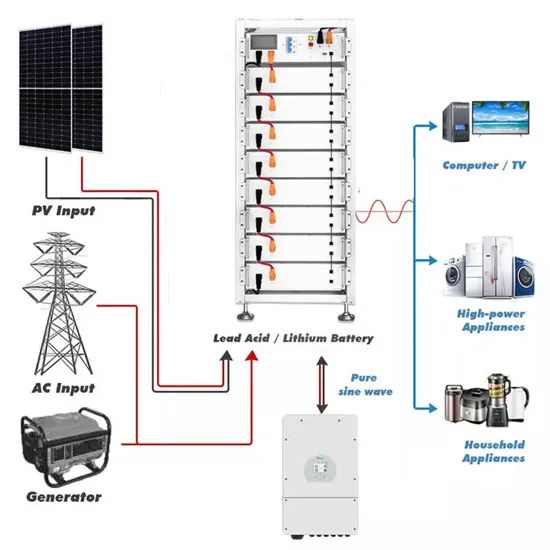

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.