Loadstar

Take care not to short circuit the battery terminals when connecting the batteries together. 3.3.1 Before starting to connect the batteries, ensure that the battery fuses within the charge cabinet

Get a quote

Choosing the Right Battery Storage Cabinet: A Comprehensive

A lithium ion battery cabinet should offer fire resistance from both the inside and outside. According to SS-EN-1363-1 testing standards, a reliable cabinet must contain an

Get a quote

DOE ESHB Chapter 3: Lithium-Ion Batteries

Various new sensors are being explored to detect battery failures such as cell venting and internal short circuits. Systems may also incorporate fire suppression technologies, such as sprinklers,

Get a quote

Owner''s Manual Extended-Run Battery Cabin

1. Introduction Tripp Lite''s Extended-Run Battery Cabinets connect to SmartOnline® UPS Systems to provide long-lasting battery backup for data centers, telecommunications,

Get a quote

Understanding the Construction & Working Principle

What is the working principle of lithium-ion battery? The working principle involves lithium ions moving from the anode to the cathode during

Get a quote

Lithium battery charging cabinet circuit

Fig 5: Lithium battery charging using an IC 555. Materials Needed; The lithium charger circuit comprises a battery, preset pins, resistors, diodes, a transformer, and the IC 555. Design

Get a quote

Guidelines for storage & usAGE of lead acid batteries

Battery Management System(BMS):Battery management systems (BMS) monitor and manage cell voltage, cell current, cell temperature, cell charge balancing, charge control, and internal

Get a quote

Battery Cabinet

This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment Engineers, and Field Support

Get a quote

BC58 Battery Cabinet Installation, Operation, & Maintenance

The option provides functional access to the equipment circuit breaker via a handle located on the exterior of a cabinet door that is physically connected to the circuit breaker in the cabinet''s

Get a quote

Electrical Fundamentals – Introduction to Batteries

The current that a cell delivers depends upon the resistance of the entire circuit, including that of the cell itself. The internal resistance of the cell depends upon the size of the electrodes, the

Get a quote

IEEE Presentation_Battery Storage 3-2021

IEEE PES Presentation _ Battery Energy Storage and Applications 3/10/2021 Jeff Zwijack Manager, Application Engineering & Proposal Development

Get a quote

How does a cabinet battery work?

To understand how a cabinet battery works, we first need to familiarize ourselves with its key components. A typical cabinet battery consists of battery cells, a battery

Get a quote

How Batteries Work – Electricity – Magnetism

In simple terms, each battery is designed to keep the cathode and anode separated to prevent a reaction. The stored electrons will only flow when the circuit is closed. This happens when the

Get a quote

Lithium ion battery internal resistance

This article will give a comprehensive introduction to the lithium ion battery internal resistance, and tell you how to measure and calculate the lithium ion battery internal resistance.

Get a quote

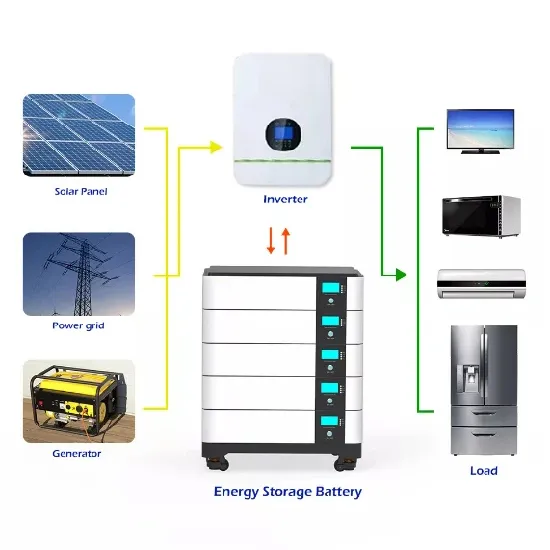

Battery Energy Storage Cabinet Control System Principle: The

Let''s pull back the curtain. The battery energy storage cabinet control system principle operates like a symphony conductor - coordinating cells, managing safety protocols, and ensuring your

Get a quote

Designing Electric Vehicle Charging Solution | EV Charger Circuit

We designed an EV Charger Solution to charge the battery efficiently. This smart charging system supports lithium-ion/lead-acid batteries.

Get a quote

100kW 215kWh All-in-One Battery Storage Cabinet

The iCON 100kW 215kWh Battery Storage System is a fully integrated, on or off grid battery solution that has liquid cooled battery storage (215kWh), inverter

Get a quote

Battery Circuit Architecture

The best design practice is to use circuitry in the battery pack that does not have an internal substrate diode to VCC. This has a side benefit of preventing the battery-pack electronics from

Get a quote

Battery Working Principle: How Batteries Generate and Store

The battery''s principle of operation is based on the concept of electrochemical reactions. When a load is connected to a battery, the chemical reactions inside the battery

Get a quote

How Batteries Work – Electricity – Magnetism

In simple terms, each battery is designed to keep the cathode and anode separated to prevent a reaction. The stored electrons will only flow when the

Get a quote

Understanding the Inner Workings of Battery: A

In addition, understanding battery schematic diagrams is important for designing and modifying battery systems. Whether it''s creating a new circuit or

Get a quote

Working Principle of Lithium Battery DC Cabinet

1. Lithium car battery principle and structure. A lithium-ion car battery is a type of battery in which charge and discharge are achieved by transferring lithium io

Get a quote

Battery cabinet electrical principle diagram video

How a battery works? This electrical potential difference or emf can be utilized as a source of voltage in any electronics or electrical circuit. This is a general and basic principle of battery

Get a quote

Utility-scale battery energy storage system (BESS)

Utility-scale BESS system description — Figure 2. Main circuit of a BESS Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the

Get a quote

6 FAQs about [Battery cabinet internal circuit principle]

What is the principle of battery operation?

The principle of battery operation is based on the conversion of chemical energy into electrical energy. The battery consists of two electrodes, a negative electrode and a positive electrode, immersed in an electrolyte solution. The electrolyte allows the movement of ions.

Why do batteries keep cathode and anode separated?

In simple terms, each battery is designed to keep the cathode and anode separated to prevent a reaction. The stored electrons will only flow when the circuit is closed. This happens when the battery is placed in a device and the device is turned on. An electric battery is essentially a source of DC electrical energy. How do batteries work?

How do you calculate the internal resistance of a battery?

Calculate the battery internal resistance: r= (U1-U2)/ (U2/R) For example, if the open circuit voltage of a battery is 12V, and the voltage drops to 10V after a 10 ohm resistor is connected in parallel, the internal resistance of the battery is r= (U1-U2)/ (U2/R)= (12-10)/ (10/10)=2 ohms.

How do batteries work?

Batteries convert stored chemical energy into electrical energy through an electrochemical process. This then provides a source of electromotive force to enable currents to flow in electric and electronic circuits. A typical battery consists of one or more voltaic cells.

What happens when a battery is connected to an external circuit?

When a battery is connected to an external circuit, a chemical reaction occurs at the electrodes. The anode releases electrons, which flow through the circuit, creating an electrical current. Simultaneously, positive ions in the electrolyte solution move towards the cathode.

Why is the internal resistance of a lithium ion battery 0?

The internal resistance and capacity are directly related. However, if the internal resistance is 0, it may be because the battery is bad. The general lithium ion battery assumes 1 amp, the internal resistance is about 30 to 80 milliohm, and the good power lithium ion battery can be less than 15 milliohm.

Guess what you want to know

-

Battery Cabinet Technical Principle

Battery Cabinet Technical Principle

-

Large battery energy storage cabinet principle base station

Large battery energy storage cabinet principle base station

-

Battery cabinet assembly automation system principle

Battery cabinet assembly automation system principle

-

Lithium battery internal energy storage cabinet price

Lithium battery internal energy storage cabinet price

-

Battery cabinet charging and discharging cabinet principle

Battery cabinet charging and discharging cabinet principle

-

What is the principle of voltage measurement in battery cabinet

What is the principle of voltage measurement in battery cabinet

-

Lithium battery station cabinet control system principle

Lithium battery station cabinet control system principle

-

Battery cabinet cooling system design principle

Battery cabinet cooling system design principle

-

The internal structure of the new energy battery cabinet

The internal structure of the new energy battery cabinet

-

Battery cabinet liquid cooling technology principle

Battery cabinet liquid cooling technology principle

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.