Additional options for battery box | Automatic extinguishing system

Expand your Batteryguard battery cabinet with additional options | Automatic extinguishing system with cooling extinguishing foam | 400-volt power connection

Get a quote

Product and Process Data Structure for Automated Battery

This article examines accessible data sources in the literature and the upcoming battery passport to build a basis for a multi-layered methodical analysis of the data required for

Get a quote

Energy storage cabinet assembly automation design

For the battery and energy storage industry, our solutions combined with powerful inspection features provide efficient, reliable and quick testing and assembly automation.

Get a quote

Battery Manufacturing Process: Materials, Production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get a quote

ATS Helps a Leading Auto Manufacturer Redefine EV

ATS Industrial Automation helps a leading automotive manufacturer ramp up its modular battery assembly systems as it transitions to an all-electric future.

Get a quote

Principle of automatic assembly of nickel sheets in battery pack

Liebherr provides modular solutions for battery pack assembly – from individual process stations through to fully automated turnkey systems. An entire modular product system is

Get a quote

Optimize Battery Assembly Line with Design and Automation

Discover the key features of a modern battery pack assembly line and how expert design and automation can boost performance, flexibility and output.

Get a quote

Smart Manufacturing: The Future of Battery Assembly

What are the Principles of Smart Manufacturing in Battery Assembly? Understanding the principles of smart manufacturing will help you understand

Get a quote

Battery assembly solution

Our automated battery assembly systems are equipped with advanced technologies such as precision handling, automated testing, and real-time monitoring to ensure every battery

Get a quote

battery cabinet,battery storage cabinet,battery bank rack

EverExceed VRL A battery assembly cabinets are very durable, and easy to install. Engineered for use with most type of battery terminal models, these cabinets can fit a wide variety of

Get a quote

Analysis of the Variety of Lithium-Ion Battery Modules and the

Within this paper the initial steps for the realisation of an agile automated system for battery module disassembly will be presented. The state of the art battery modules need to be

Get a quote

Battery Pack Assembly Fixture Design Principles

Designing an effective battery pack assembly fixture requires balancing precision, durability, and adaptability. Unlike generic jigs, these fixtures must account for unique

Get a quote

Battery Assembly Systems

Servo powered, precision-controlled pressing is often required for battery assembly. Force and position monitoring is used for achieving accuracy when assembling press-fit components.

Get a quote

Smart Manufacturing: The Future of Battery Assembly Solution

What are the Principles of Smart Manufacturing in Battery Assembly? Understanding the principles of smart manufacturing will help you understand why more and more businesses are

Get a quote

Battery Module & Pack Manufacturing: Step-by-Step

As India and other emerging markets ramp up battery pack assembly, the global blueprint is clear: automation, flexibility, and integrated

Get a quote

Battery Cabinets | Electronic Connectors | Arimon

Top Terminal (Monobloc) Battery Cabinets Arimon offers several standard monobloc or top terminal battery cabinet sizes for 10 kVA to 125 kVA UPS

Get a quote

Battery cabinet assembly principle of battery cabinet

an important equipment for the battery aging process. The quality of battery aging determines the safety, stability, service life and battery performance of the battery in actual use. Therefore, the

Get a quote

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these, lead

Get a quote

Automation of Operations in Assembly of Battery Modules in

This paper provides proposals for potential applications where deployment of robotic automation in the battery module assembly context can be explored. The paper investigates

Get a quote

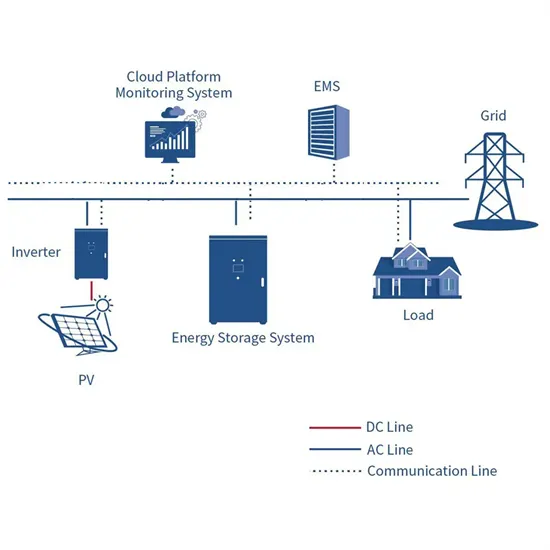

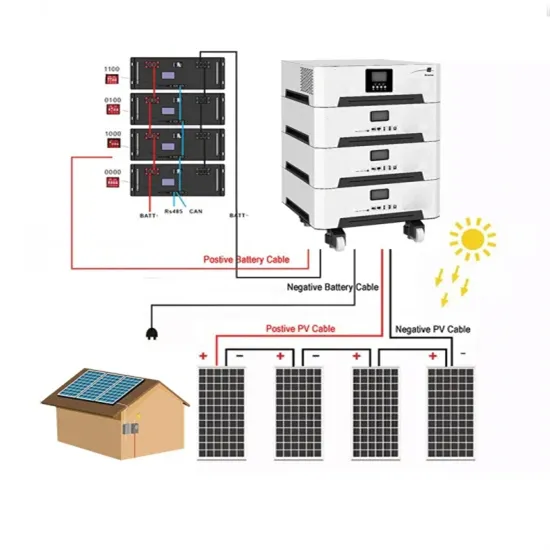

100kW 215kWh All-in-One Battery Storage Cabinet

The iCON 100kW 215kWh Battery Storage System is a fully integrated, on or off grid battery solution that has liquid cooled battery storage (215kWh), inverter

Get a quote

Automatic assembly principle of energy storage cabinet

We use the latest technologies to build state-of-the-art automation solutions to assemble and inspect battery packs and other energy storage systems, ensuring the reliability and high

Get a quote

Guess what you want to know

-

Battery Cabinet Base Station Energy Automation Technology Principle

Battery Cabinet Base Station Energy Automation Technology Principle

-

Saint Lucia New Energy Battery Cabinet Assembly

Saint Lucia New Energy Battery Cabinet Assembly

-

Energy storage cabinet assembly automation equipment

Energy storage cabinet assembly automation equipment

-

Lithium battery energy storage cabinet assembly manufacturer

Lithium battery energy storage cabinet assembly manufacturer

-

Large battery energy storage cabinet principle base station

Large battery energy storage cabinet principle base station

-

Lithium iron phosphate 220v outdoor battery cabinet assembly

Lithium iron phosphate 220v outdoor battery cabinet assembly

-

Working Principle of DC Battery Cabinet

Working Principle of DC Battery Cabinet

-

Battery cabinet liquid cooling technology principle

Battery cabinet liquid cooling technology principle

-

12v lithium battery large monomer assembly outdoor battery cabinet

12v lithium battery large monomer assembly outdoor battery cabinet

-

North Macedonia lithium battery energy storage cabinet assembly plant

North Macedonia lithium battery energy storage cabinet assembly plant

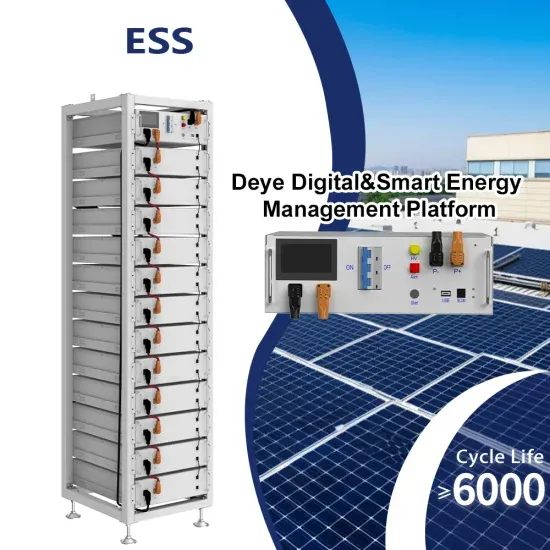

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.