How AZE Systems Manufactures BESS Battery Energy Storage Cabinets

Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

Get a quote

HuiYao Intel

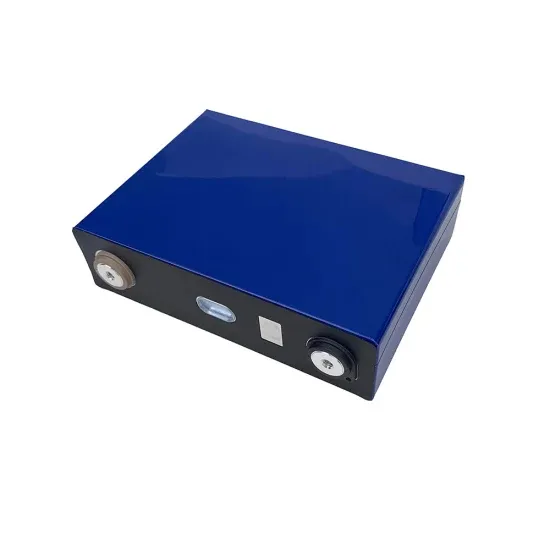

Our production line for prismatic battery modules stands out for its ability to meet the growing demands of the energy storage market. By prioritizing this sector, we aim to provide reliable

Get a quote

How AZE Systems Manufactures BESS Battery Energy Storage

Manufacturing a Battery Energy Storage System (BESS) cabinet is a complex process that involves designing, engineering, and assembling a robust and reliable system to

Get a quote

Energy storage technology service cabinet

This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with MES through a scheduling system, achieving

Get a quote

The Art and Science of Energy Storage Equipment Assembly: A

Let''s face it – when most people hear "energy storage equipment assembly," they imagine technicians casually snapping battery modules together like LEGO bricks.

Get a quote

Energy storage cabinet assembly automation design

For the battery and energy storage industry, our solutions combined with powerful inspection features provide efficient, reliable and quick testing and assembly automation.

Get a quote

Energy storage technology service cabinet

Energy storage technology service cabinet This production line is used for auto. atic assembly of energy storage cabinets. All single machine equipment and distributed systems interact with

Get a quote

Energy storage cabinet assembly process

The assembly process is a vital step in the creation of high-quality 20ft energy storage containers. By choosing TLS Offshore Containers, you can be confident that your Sodium-Sulfur (Na-S)

Get a quote

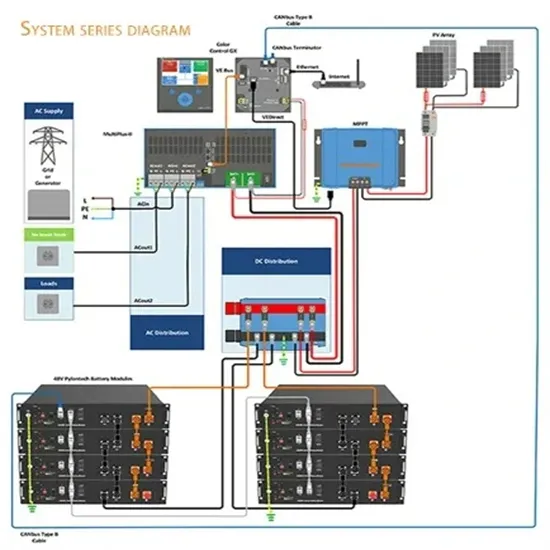

Energy storage

With its flexible, scalable modular system, Rittal makes it easier for you to set up energy storage systems and offers you a range of components that are perfectly matched to one another:

Get a quote

Pack energy storage cabinet assembly

The scalable design focuses on a front of the meter grid scale battery energy storage system with typical storage capacity ranging from around 4,400 kWh to 100 MWh and more. When

Get a quote

Energy storage drawer cabinet assembly line

The energy storage drawer cabinet production line adopts double-speed chain conveying lines, roller conveying lines and AGVs (automatic guided transport vehicles) to reduce material

Get a quote

Fluence | A Siemens and AES Company

Fluence offers energy storage products that are optimized for common customer applications but can be configured for specific use cases and requirements. All Fluence products can be

Get a quote

Battery Energy Storage Manufacturing Automation | JR Automation

At JR Automation, our capabilities extend far beyond battery module and EV powertrain assembly. We''re here to help you design automation solutions for battery energy

Get a quote

Custom Metal Enclosures, Cabinets & Box

Saipwell specializes in custom Metal Enclosures, Cabinets, Boxes, and NEMA Enclosures. We offer fast production, flexible customization, cost-effective

Get a quote

Energy Storage Cabinet Production Line

The AGV flexible logistics system is used to achieve automatic assembly process of energy storage cabinets, rapidly improving product production efficiency and stability.

Get a quote

What are the energy storage cabinet assembly equipment

Flexible,scalable design for efficient energy storage. Energy storage is critical to decarbonizing the power system and reducing greenhouse gas emissions. It''s also essential to build

Get a quote

Energy Storage Cabinet Equipment: The Unsung Hero of Modern

Imagine having a Swiss Army knife for electricity - that''s essentially what modern energy storage cabinet equipment brings to the table. These unassuming metal boxes are revolutionizing how

Get a quote

Leading Energy Storage Equipment Manufacturer

Are you looking for reliable and efficient energy storage solutions? Look no further than our high-tech enterprise, a leading innovator in the field of energy storage

Get a quote

Energy storage cabinet assembly production line process

Energy storage cabinet assembly production line process What is the production process for chisage ESS battery packs? The production process for Chisage ESS Battery Packs consists

Get a quote

Guess what you want to know

-

What are the energy storage cabinet assembly equipment

What are the energy storage cabinet assembly equipment

-

Brunei Energy Storage Cabinet Equipment Manufacturer

Brunei Energy Storage Cabinet Equipment Manufacturer

-

Energy storage container assembly automation design

Energy storage container assembly automation design

-

Lithuanian energy storage cabinet equipment manufacturer

Lithuanian energy storage cabinet equipment manufacturer

-

Lithium battery energy storage cabinet assembly manufacturer

Lithium battery energy storage cabinet assembly manufacturer

-

Which factories need energy storage cabinet equipment

Which factories need energy storage cabinet equipment

-

Mauritius New Energy Storage Cabinet Assembly Company

Mauritius New Energy Storage Cabinet Assembly Company

-

Yemen Intelligent Energy Storage Cabinet Equipment

Yemen Intelligent Energy Storage Cabinet Equipment

-

Energy storage cabinet automation system design

Energy storage cabinet automation system design

-

Energy storage battery cabinet assembly process base station

Energy storage battery cabinet assembly process base station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.