Battery gauging fundamentals

Instrumentation in system: Highly accurate voltage, current and temperature measurements Useful for system characterization and production tests Assist with power management:

Get a quote

Megohmmeter Working Principle

Battery powered Megohmmeters are also available, and these are essentially very high resistance ohmmeters. The battery voltage is typically increased (by

Get a quote

Principle of new energy high voltage battery cabinet

What is a high-voltage battery? High-voltage batteries are rechargeable energy storage systems that operate at significantly higher voltages than conventional batteries, typically ranging from

Get a quote

What is Battery Voltage? Why Does It Matter and How

The battery voltage is the measure of electric potential difference between the two terminals. Understanding the battery voltage is very important, as it lets you

Get a quote

Simplify Voltage and Current Measurement in Battery Test

Voltage and current sensing are the two most significant measurements in battery test equipment systems. Furthermore, the most important parametric characteristics for this application is a

Get a quote

LLVD & BLVD in Base Station Power Cabinets

LLVD and BLVD Protection in Base Station Power Cabinets Introduction In modern communication networks, base stations, as core infrastructure, are

Get a quote

Measuring Battery Voltage

Connect the red alligator clip wire of the voltage sensor to the positive terminal and the black clip wire to the negative terminal. Press the button to measure the voltage and record the battery

Get a quote

Voltage, Current, Resistance, and Ohm''s Law

Electricity Basics When beginning to explore the world of electricity and electronics, it is vital to start by understanding the basics of voltage, current, and resistance. These are the three

Get a quote

How to design an intelligent battery junction box for

The main function of a battery management system (BMS) is to monitor cell voltages, pack voltages and pack current. In addition, due to the high-voltage design of the BMS, insulation

Get a quote

How to measure the voltage of batteries in the battery cabinet

At its most basic, battery voltage is a measure of the electrical potential difference between the two terminals of a battery--the positive terminal and the negative terminal.

Get a quote

How to Measure Battery Voltage with a Multimeter | Fluke

Follow this step-by-step guide to measure battery voltage with a multimeter. Measuring battery voltage is a fast, essential way to determine the state of charge.

Get a quote

Battery Testing Procedure

Discover the step-by-step battery testing procedure, including how to measure voltage, capacity, and internal resistance. Using this comprehensive guide, you can ensure

Get a quote

What is Battery Voltage? Why Does it Matter?

Voltage is a measure of the electric potential difference between two points in an electrical circuit. In the context of batteries, voltage refers to the force that

Get a quote

Understanding the Lithium

Working Principle The basic working principle of a lithium - battery aging cabinet is centered around mimicking real - world usage scenarios for the batteries. When a new lithium

Get a quote

Battery Internal Ohmic Measurements Explained

To take a battery impedance measurement a change in voltage has to occur. The battery impedance is dependent on the rate of change (frequency) and amplitude of the test

Get a quote

Battery Pack Voltage Measurement: What You Need to Know

This article outlines the key considerations for accurately monitoring voltage and temperature in high-voltage battery packs, helping to support safer and more efficient EV development.

Get a quote

What is Battery Voltage? Why Does It Matter and How to Measure

The battery voltage is the measure of electric potential difference between the two terminals. Understanding the battery voltage is very important, as it lets you know the maximum power

Get a quote

What is Battery Voltage? Why Does it Matter?

Voltage is a measure of the electric potential difference between two points in an electrical circuit. In the context of batteries, voltage refers to the force that pushes electric charge through a

Get a quote

Voltage Sensor: Working Principle, Types & Circuit

Key learnings: Voltage Sensor Definition: A voltage sensor is a device that measures voltage in an object, handling both AC and DC types.

Get a quote

Step-by-Step Battery Capacity Testing Procedure

Step-1: Ensure instrumentation is operational & properly connected to the battery for continuous monitoring of discharge voltage and current. Step-2: Measure the float voltage

Get a quote

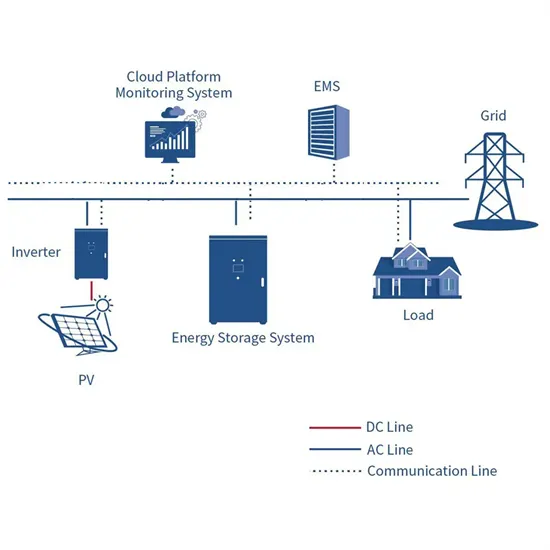

What is the principle of energy storage cabinet | NenPower

Energy storage cabinets function primarily on the principle of storing energy for future use, enhancing energy efficiency, and providing backup power. These systems harness

Get a quote

Basics of Potentiostats and Galvanostats: Principles

Principle: The instrument controls the current, forcing ions to move into or out of the electrode materials. By measuring the voltage change over

Get a quote

Methods to Measure Open Circuit Voltage on a Battery Pack

This application note describes several ways of measuring open circuit voltage on a battery pack including at the full pack level, on individual cells that are connected in parallel and on

Get a quote

Methods to Measure Open Circuit Voltage on a

This application note describes several ways of measuring open circuit voltage on a battery pack including at the full pack level, on individual cells that are

Get a quote

6 FAQs about [What is the principle of voltage measurement in battery cabinet]

How do you measure a battery impedance?

There is no industry standard specifying the method for taking a battery impedance measurement, e.g., test signal amplitude or test signal frequency. Therefore, each device manufacturer is using their own recipe. The battery is not a simple resistor, hence the need to measure impedance.

How do you test a battery with a multimeter?

Connect multimeter probes to battery & measure the voltage. The voltage should fall across the specified in the cell or battery’s datasheet. For NMC (Nickel-Manganese-Cobalt), this will range between 2.5 V & 4.2 V per cell. An LFP (Lithium Iron Phosphate) cell (or) battery will have a voltage between 2.5 V and 3.7 V.

What is battery testing?

Battery testing comprises measuring the voltage, capacity, & other parameters of the battery with the help of a multimeter or another equipment. You will be able to tell whether a battery is defective, weak, or needs to be changed based on the results of the tests performed on the battery. What is the purpose of Battery Testing?

Can voltage predict a battery's state of Health?

Voltage alone cannot predict a battery’s state of health (SoH). Connect multimeter probes to battery & measure the voltage. The voltage should fall across the specified in the cell or battery’s datasheet. For NMC (Nickel-Manganese-Cobalt), this will range between 2.5 V & 4.2 V per cell.

How does a battery impedance test work?

To take a battery impedance measurement a change in voltage has to occur. The battery impedance is dependent on the rate of change (frequency) and amplitude of the test signal applied to the battery. To cause a change on the battery, depending on the equipment used the test signal may draw out energy, inject energy or both.

How do you test a battery pack?

This testing can be a bottleneck in the manufacturing process, so test solutions that reduce time or increase test density are highly desirable. One of the most useful measurements for a battery cell or pack is the open circuit voltage (OCV), but the considerations that must be made at the module or pack level differ from the cell level.

Guess what you want to know

-

What is the voltage of the new power battery cabinet

What is the voltage of the new power battery cabinet

-

What is the battery cabinet used for communication high voltage cabinet

What is the battery cabinet used for communication high voltage cabinet

-

What is the appropriate voltage for the new power battery cabinet

What is the appropriate voltage for the new power battery cabinet

-

What is the voltage and current of the energy storage cabinet battery

What is the voltage and current of the energy storage cabinet battery

-

What are the battery cabinet factories in Bangladesh

What are the battery cabinet factories in Bangladesh

-

What are the battery cabinet temperature control systems

What are the battery cabinet temperature control systems

-

What is the capacity of the battery in the battery cabinet

What is the capacity of the battery in the battery cabinet

-

Battery cabinet charging and discharging cabinet principle

Battery cabinet charging and discharging cabinet principle

-

What are the battery cabinet layout requirements

What are the battery cabinet layout requirements

-

What should I do when replacing the new battery cabinet at the telecom site

What should I do when replacing the new battery cabinet at the telecom site

Industrial & Commercial Energy Storage Market Growth

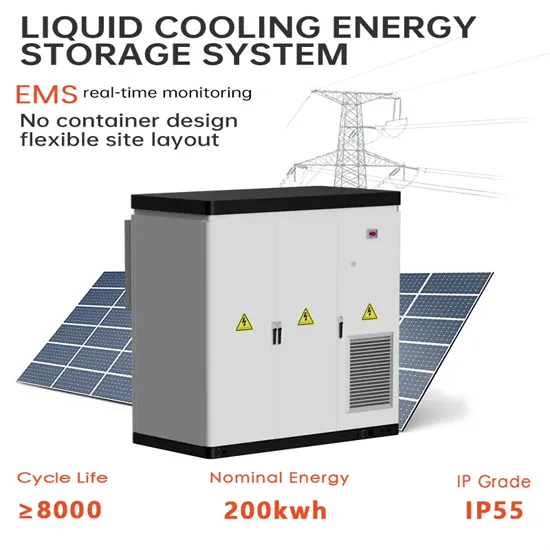

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

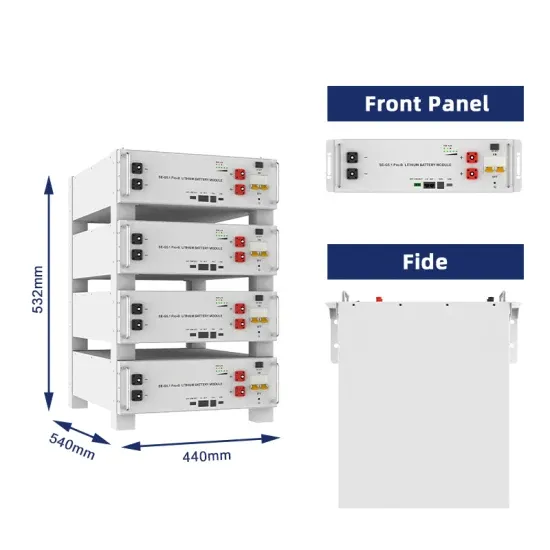

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.