What Size Inverter Can I Run Off a 200Ah Lithium Battery?

A 200Ah lithium battery at 12V supports inverters up to about 2400W; 24V and 48V models support larger inverters up to 4000W and 8000W respectively. Always use pure

Get a quote

What Gauge Wire to Connect 12v Batteries (Parallel

Choosing the right gauge wire for connecting 12V batteries is crucial. Here''s how to make the right choice for your 12 batteries in parallel or

Get a quote

Which Inverter is Suitable for a 200Ah Battery?

Choosing the right inverter for a 200Ah battery depends on several factors, including the load size, runtime, and efficiency. The 200Ah battery is large enough to handle

Get a quote

MPPT charge controller calculator: Find the right solar charge

Example 1: 200W-12V solar array with a 12V battery bank For the first example, we have 2 100W-12Vwatts solar panels, these panels are wired in series and need to charge a

Get a quote

Choosing the Best Inverter Size for a 200Ah Lithium

Using an inverter that is too large or too small for your 200Ah lithium battery can lead to inefficiency, overheating, system shutdowns, or battery

Get a quote

Which inverter is best for 200ah battery?

Factors to Consider for a 200Ah Battery-Compatible Inverter. Most 200Ah batteries operate at 12V or 24V. Ensure the inverter matches the battery''s voltage. A mismatch can lead to

Get a quote

Can I use 12V or 24V 200AH battery with 1000W inverter?

This can reduce charging time and extend the life of the battery. Conclusion In a 1000-watt power inverter system, both 12V and 24V 200AH batteries can be used, but their

Get a quote

What Size Inverter Do I Need?

Learn how to calculate what size inverter you need with The Inverter Store''s handy guide. We make the process straightforward for you to fit your exact

Get a quote

Choosing the Best Inverter Size for a 200Ah Lithium Battery

Using an inverter that is too large or too small for your 200Ah lithium battery can lead to inefficiency, overheating, system shutdowns, or battery damage. Ensuring that your

Get a quote

What Size Inverter Do I Need for a 200Ah Lithium Battery

For a 12V 200Ah lithium battery, a 1500W to 2000W inverter is recommended to ensure efficient performance with headroom for surge loads. Proper sizing enhances system

Get a quote

What Size Inverter Can I Run Off a 200Ah Battery?

Suitable inverters for a 200Ah battery should match the system voltage (e.g., 12V) and handle the desired load power. Pure sine wave inverters are often preferred for sensitive electronics.

Get a quote

Choosing the Best Inverter Size for a 200Ah Lithium Battery

To calculate the wire and fuse size needed for the inverter you would take the inverter wattage, divide by 12V, then divide by 85% efficiency.

Get a quote

Microtek DuraStrong | MTK2003624TT 200Ah Inverter

Microtek DuraStrong | MTK2003624TT 200Ah Inverter Battery | with Advanced Dura Core Technology for Longer Battery Life | Suitable for Home, Office &

Get a quote

What Size Inverter Is Best for a 200Ah Battery?

A 200Ah battery typically pairs with a 1,500W–3,000W inverter, depending on power needs. For continuous loads, select an inverter with 1.5x your calculated wattage to avoid overloads.

Get a quote

What Size Inverter Can I Run Off a 200Ah Battery?

Suitable inverters for a 200Ah battery should match the system voltage (e.g., 12V) and handle the desired load power. Pure sine wave inverters are often preferred for sensitive

Get a quote

What Size Wire For Any Inverter: Inverter Wire Size

Choosing the right cables for your inverter can be downright confusing. This guide helps you find the right size wire for any sized inverter.

Get a quote

What Size Inverter Do I Need for a 200AH Battery?

Choosing the right inverter size for a 200AH battery is crucial for ensuring optimal performance and efficiency. This section provides detailed insights into how to calculate the

Get a quote

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

Inverter capacity (W)*Runtime (hrs)/solar system voltage = Battery Size*1.15. Multiply the result by 2 for lead-acid type battery, for lithium battery type it would stay the

Get a quote

What Size Charger Is Best for a 200Ah Battery with Inverter

For a 200Ah battery paired with an inverter, a charger rated at 20-40 amps (10-20% of the battery''s capacity) is ideal. Voltage must match the battery bank (12V, 24V, or

Get a quote

How Do You Calculate the Appropriate Inverter Size for a 48V

To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

Get a quote

How Long Will a 2000W Inverter Run on a 200Ah Battery?

A 200Ah battery can theoretically power a 2000W inverter for approximately 1.2 hours under ideal conditions. However, actual runtime may vary based on factors such as inverter efficiency,

Get a quote

Best Inverter for 200Ah Battery: A Complete Guide 2025

Find the best inverter for your 200Ah battery setup. Compare top models, get expert tips, and shop reliable inverters for RVs, homes, and off-grid use.

Get a quote

Lithium Batteries: What Size Inverter Can I Use?

When calculating the amp usage of an inverter, you take the output wattage of the inverter and divide it by the battery voltage, i.e. 1000W ÷ 12V = 83.33 Amps. The other question we always

Get a quote

Calculate Battery Size For Any Size Inverter (Using

Inverter capacity (W)*Runtime (hrs)/solar system voltage = Battery Size*1.15. Multiply the result by 2 for lead-acid type battery, for lithium battery

Get a quote

12V LiFePO4 terminal fuse type and sizing

Right now the top battery choice is a PowerUrUs 12V 200 Ah battery, two batteries in parallel. Four 100Ah batteries in parallel with 100A BMSs is a possibility. I was thinking of

Get a quote

6 FAQs about [What size inverter is suitable for 12v 200ah]

How do I choose the right inverter size for my 200Ah lithium battery?

When it comes to choosing the right inverter size for your 200Ah lithium battery, there are a few factors you’ll need to consider. The first is the power needs of the devices you plan on running off the inverter. Take into account their wattage requirements and how many devices will be connected at once.

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

How to choose the best 12V to 240 inverter?

When selecting a power inverter, there are some factors that should be considered for choosing the best 12v to 240 inverters. The size and type of the power inverter are two important factors. The size of the inverter is determined by the wattage that it can handle. The type of the inverter is determined by the voltage that it can handle. 1.

How much battery do I need to run a 3000-watt inverter?

You would need around 24v 150Ah Lithium or 24v 300Ah Lead-acid Battery to run a 3000-watt inverter for 1 hour at its full capacity Here's a battery size chart for any size inverter with 1 hour of load runtime Note! The input voltage of the inverter should match the battery voltage.

How do I calculate the battery capacity of a solar inverter?

Related Post: Solar Panel Calculator For Battery To calculate the battery capacity for your inverter use this formula Inverter capacity (W)*Runtime (hrs)/solar system voltage = Battery Size*1.15 Multiply the result by 2 for lead-acid type battery, for lithium battery type it would stay the same Example

Who can use a 12V to 230V power inverter?

A 12V to 230V power inverter is ideal for a multitude of users, including caravaners, truck drivers, doctors, electricians, joiners, and anyone who enjoys camping or boating.

Guess what you want to know

-

What size inverter is suitable for 72v 32ah

What size inverter is suitable for 72v 32ah

-

What size inverter should I use for a 36v solar panel

What size inverter should I use for a 36v solar panel

-

What brand of 12v high power inverter is good

What brand of 12v high power inverter is good

-

What size inverter can I use with a 48v lithium battery

What size inverter can I use with a 48v lithium battery

-

What size inverter should I use for a 220v 350w motor

What size inverter should I use for a 220v 350w motor

-

What is the difference between a 12v inverter and a 24v inverter

What is the difference between a 12v inverter and a 24v inverter

-

What inverter do I need for 5 12v solar panels

What inverter do I need for 5 12v solar panels

-

What size battery should I use with a power frequency inverter

What size battery should I use with a power frequency inverter

-

What is the current of a 12v inverter

What is the current of a 12v inverter

-

Does a 12v inverter and a 24v inverter consume about the same amount of power

Does a 12v inverter and a 24v inverter consume about the same amount of power

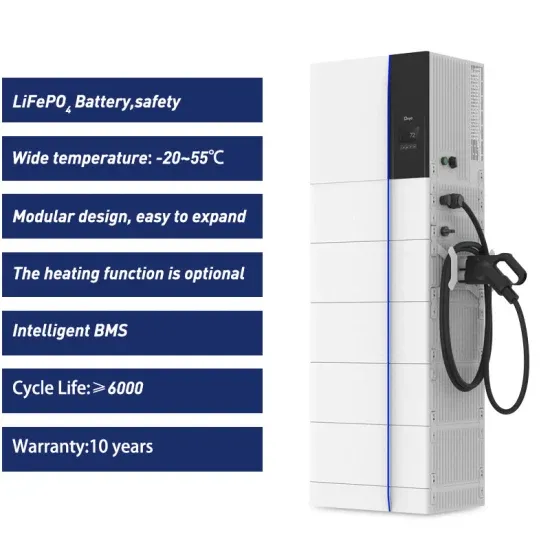

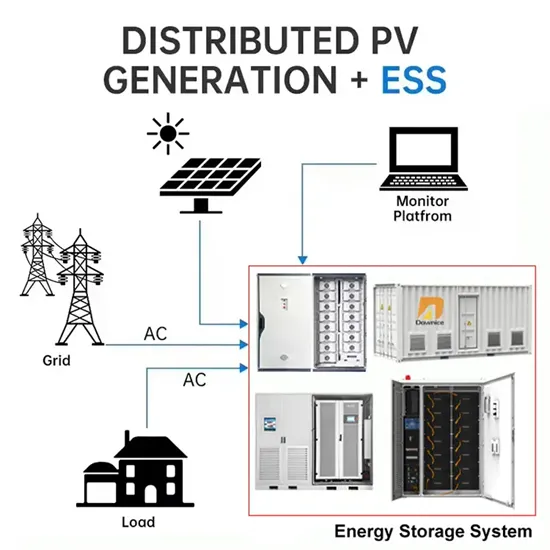

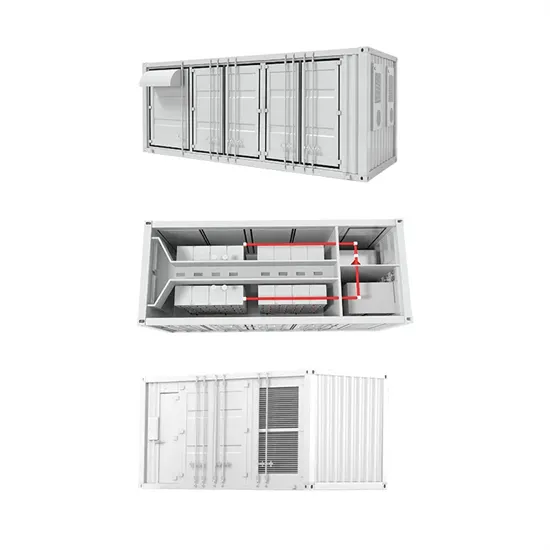

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.