What Inverter Do I Need for a 48V Battery?

To safely and efficiently use a 48V lithium battery, choose a 48V-rated pure sine wave or hybrid inverter, sized to your daily load, and compatible with CAN or RS485 BMS communication.

Get a quote

What Size Lithium Battery Do I Need for a 5kW Inverter?

To power a 5kW inverter, you typically need a lithium battery capacity of around 200Ah at 48V or 400Ah at 24V. This capacity ensures sufficient energy storage for typical usage scenarios,

Get a quote

48V or 51V battery

I see batteries with 48 and with 51V - they are very close only 3 V difference. Which one should I choose? What dictates what voltage to be used? Is 48V made out of 15

Get a quote

How to Determine What Size Inverter You Can Run Off a 100Ah Battery

Determining the appropriate size of an inverter that can be run off a 100Ah battery involves understanding both the power output of the inverter and the energy capacity of the battery. A

Get a quote

How to Calculate Battery Size for Inverters of Any Size

Learn how to calculate how much battery power you need to get your inverter up and running with The Inverter Store''s handy how-to guide. It works for any size.

Get a quote

How to Choose the Right Inverter for Lithium Batteries?

Answer: To choose the right inverter for lithium batteries, match the inverter''s voltage and capacity to your battery''s specifications, prioritize pure sine wave inverters for

Get a quote

What Size Lithium Battery Do I Need to Run a 5000W Inverter?

For a 5000W power inverter, a 48V 600Ah lead-acid battery is often recommended. Lead-acid batteries are typically heavier, have a shorter lifespan, and take longer to charge compared to

Get a quote

Can I Attach My Small Inverter Directly to the Battery?

Yes, you can attach a small inverter directly to a battery, but doing it safely requires understanding voltage compatibility, wire sizing, and overload risks. Many DIYers assume it''s

Get a quote

Best Solar Lithium Battery for Off-Grid Systems in 2025

3 days ago· 2025 guide to choosing the best solar lithium battery for off-grid: LiFePO4, 48V, BMS protection, MPPT settings, sizing math, and compliance standards.

Get a quote

Lithium Batteries: What Size Inverter Can I Use?

Bottom line, if you want to run large inverter loads above 1000w on a lithium battery, make sure you choose an lithium battery that is designed for larger

Get a quote

How Do You Calculate the Appropriate Inverter Size for a 48V Battery

To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

Get a quote

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

To recharge your battery from time to time you would need the right size solar panel to do the job! Read the below article to find out the suitable solar panel size for your battery bank

Get a quote

Lithium Batteries: What Size Inverter Can I Use?

Bottom line, if you want to run large inverter loads above 1000w on a lithium battery, make sure you choose an lithium battery that is designed for larger inverters or a system that can be

Get a quote

A Complete Overview of 48V Batteries and Their

Understanding the Basics of 48V Battery Systems What Defines a 48V Battery? A 48V battery system typically consists of multiple cells

Get a quote

How Do You Calculate the Appropriate Inverter Size for a 48V

To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

Get a quote

Lithium (LiFePO4) Battery Runtime Calculator

Note: Use our solar panel size calculator to find out what size solar panel you need to recharge your battery. Calculator assumption Lithium battery discharge efficiency: 95%

Get a quote

What Inverter Do I Need for a 48V Battery?

To safely and efficiently use a 48V lithium battery, choose a 48V-rated pure sine wave or hybrid inverter, sized to your daily load, and compatible with CAN or

Get a quote

Can an Inverter Be Too Big for Your Battery System?

A 48V 100Ah lithium battery (4.8kWh) paired with a 5000W inverter works because 48V × 100Ah × 1C = 4800W. Always account for inverter efficiency losses (typically 85-95%). For mixed

Get a quote

Compatibility of LiFePO4 Batteries and Chargers/Inverters

Ensuring compatibility between LiFePO4 batteries and chargers or inverters is crucial for optimal performance and safety. Key factors include understanding charging

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

So I''m gonna explain to you guys in simple words about what you can run on your any size inverter and what are the key point to keep in mind. And also how long your inverter

Get a quote

What Size Inverter To Charge E-Bike Battery? [With

However, finding the right inverter size and a proper way of charging the e-bike battery can help you in times of need. So, take help from this guide whenever

Get a quote

What Size Inverter Do I Need for a 200Ah Lithium

When determining the appropriate inverter size for a 200Ah lithium battery, several key factors must be considered, including the battery''s

Get a quote

What Size Inverter Do I Need?

This can be useful to find the right battery size for your inverter (which you can calculate using our handy guide) or for measuring the necessary volts. You

Get a quote

What Will An Inverter Run & For How Long? (With

So I''m gonna explain to you guys in simple words about what you can run on your any size inverter and what are the key point to keep in mind.

Get a quote

What Size Lithium Battery Is Needed for a 2000W Inverter

Short A 2000W inverter typically requires a 200Ah lithium battery (24V) or 100Ah (48V) for 1 hour of runtime. For longer use, multiply by desired hours. Prioritize voltage compatibility, depth of

Get a quote

6 FAQs about [What size inverter can I use with a 48v lithium battery ]

Can a lithium battery run a large inverter?

Bottom line, if you want to run large inverter loads above 1000w on a lithium battery, make sure you choose an lithium battery that is designed for larger inverters or a system that can be paralleled safely with active balancing between the connected batteries.

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

Does an inverter convert a battery into a 120 volt battery?

Our batteries come in different voltages (12,24, & 48v) But AC appliances required 120 volts (because our grid power comes in 120 volts). So an inverter will convert the lower voltage of the battery into 120 volts in order to run AC appliances If playback doesn't begin shortly, try restarting your device.

How much battery do I need to run a 3000-watt inverter?

You would need around 24v 150Ah Lithium or 24v 300Ah Lead-acid Battery to run a 3000-watt inverter for 1 hour at its full capacity Here's a battery size chart for any size inverter with 1 hour of load runtime Note! The input voltage of the inverter should match the battery voltage.

What size inverter do you need for a microwave?

With this load you would install a minimum of 1500w inverter. This size inverter will allow you to run the microwave and have a little left over for running small items like phone charger, fan etc. With today’s lithium batteries, inverters play a big part due to the energy that a lithium battery can deliver.

What size inverter do I Need?

Let’s say your largest load is a microwave. A typical microwave will draw between 900-1200w. With this load you would install a minimum of 1500w inverter. This size inverter will allow you to run the microwave and have a little left over for running small items like phone charger, fan etc.

Guess what you want to know

-

What size battery should I use with a power frequency inverter

What size battery should I use with a power frequency inverter

-

What size inverter should I use for a 12 volt battery

What size inverter should I use for a 12 volt battery

-

What size battery should I use with a 24v 8000 inverter

What size battery should I use with a 24v 8000 inverter

-

What size battery inverter to use

What size battery inverter to use

-

What battery should I use with the inverter

What battery should I use with the inverter

-

Can the inverter be connected to a 48V lithium battery

Can the inverter be connected to a 48V lithium battery

-

Energy storage inverter connected to 48v lithium battery

Energy storage inverter connected to 48v lithium battery

-

What battery should I use with the inverter

What battery should I use with the inverter

-

What charging mode does the 48v inverter use

What charging mode does the 48v inverter use

-

What size inverter should I use for a 40kw photovoltaic system

What size inverter should I use for a 40kw photovoltaic system

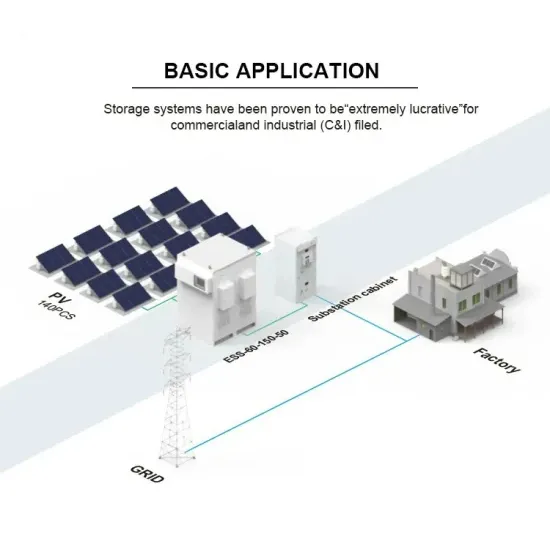

Industrial & Commercial Energy Storage Market Growth

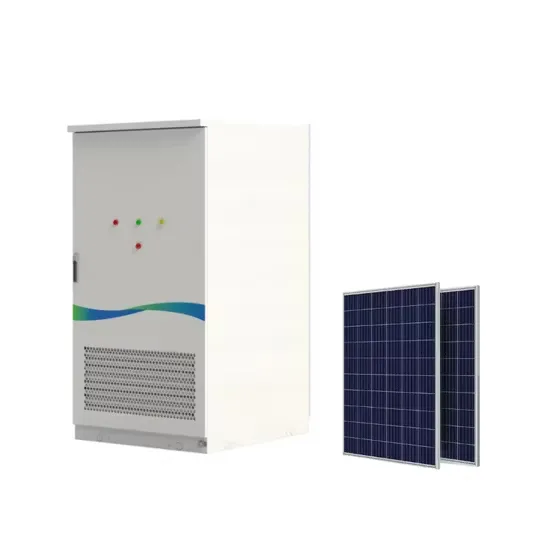

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

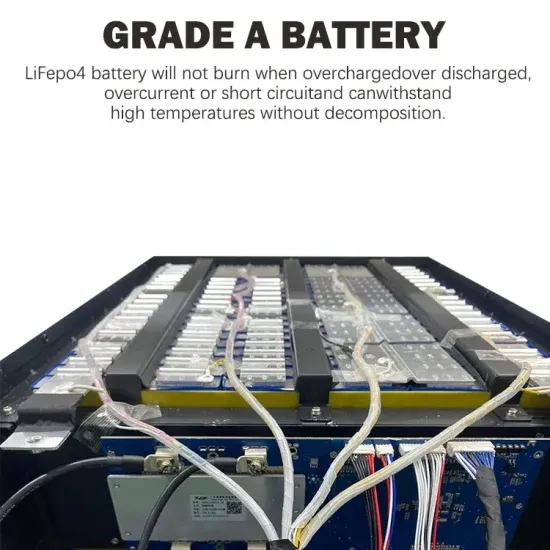

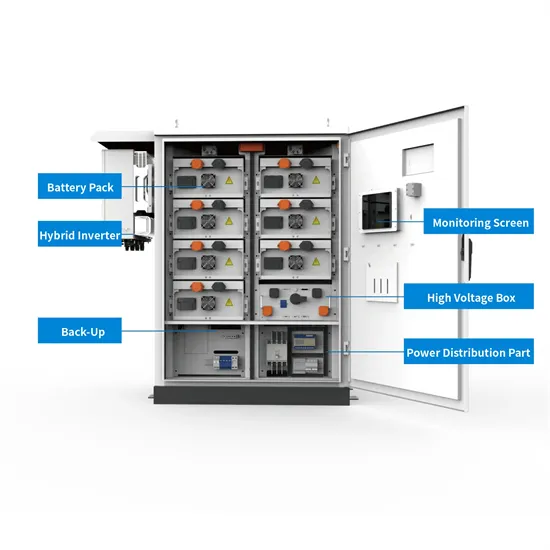

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.