ESTEL Outdoor Battery Cabinet Buying Guide for 2025

Find tips to choose the best outdoor battery cabinet for your energy needs, focusing on size, cooling, durability, and future expansion options.

Get a quote

How does the energy storage battery cabinet dissipate heat?

The energy storage battery cabinet dissipates heat primarily through 1. ventilation systems, 2. passive heat sinks, 3. active cooling methods, and 4. thermal management protocols.

Get a quote

Eaton DX 6-10kVA UPS Site Planning Guide

Below you will find brief information for 6kVA DX Series, 10kVA DX Series. This Site Planning Guide provides essential details for the installation and setup of the Eaton E Series DX 6

Get a quote

How Do Thermal Standards Ensure Safety in High-Density Battery

Key standards like UL 1973, IEC 62619, and NFPA 855 define requirements for heat dissipation, fire resistance, and system design. Compliance reduces fire risks, extends battery lifespan,

Get a quote

Battery Room Ventilation and Safety

It is a condition when the heat generation rate inside the battery is faster than the heat dissipation. To prevent the failure and the battery dry out, the safety valves open and the battery vents

Get a quote

Large-Capacity Enclosed Outdoor Cabinets (T

When the cabinet service capacity is increased or services with higher rates are provisioned, enhanced dissipation modules can be installed in the cabinets to

Get a quote

container energy storage cabinet installation requirements

Liquid Cooling Outdoor Energy Storage Cabinet -HyperStrong The "all-in-one" design integrates batteries, BMS, liquid cooling system, heat management system, fire protection system, and

Get a quote

Solutions

The flexible rectifier system and aluminium outdoor cabinet configuration is the tailored solution for your base station demand. Delta Outdoor ECO Cooling Enclosure fulfills the client''s cooling

Get a quote

UPS (Uninterruptible Power Supply) thermal

1 termine thermal requirements: Calculate the heat dissipation requirements for the UPS based on its power rating. This information is

Get a quote

What need for temperature control and ventilation to battery

The design of battery rooms should be completed using passive heat dissipation so that no UPS support to cooling equipment is required. The following should be investigated

Get a quote

What need for temperature control and ventilation to

The design of battery rooms should be completed using passive heat dissipation so that no UPS support to cooling equipment is required. The

Get a quote

Do Lithium Ion Batteries Require A Battery Room? Storage

Excessive heat can accelerate chemical reactions inside the battery, causing it to swell, leak, or even burst. Additionally, physical damage to the battery, such as punctures or

Get a quote

Designing Industrial Battery Rooms: Fundamentals and Standards

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards.

Get a quote

Battery cabinet heat dissipation

IntelliBatt cabinet, which features a built-in battery monitoring system that is visible via integrated in-door viewing panels, and includes the ability to accommodate different battery sizes and

Get a quote

EB-ThermalEdge-ThermalManagement-Revised-02.10.16

All share a common problem: The heat load of the digital equipment in these cabinets has been growing exponentially over the last decade. This has fueled the need to install cabinet cooling

Get a quote

How Do Thermal Standards Ensure Safety in High-Density

Key standards like UL 1973, IEC 62619, and NFPA 855 define requirements for heat dissipation, fire resistance, and system design. Compliance reduces fire risks, extends battery lifespan,

Get a quote

Do Lithium Ion Batteries Require A Battery Room? Storage Requirements

Excessive heat can accelerate chemical reactions inside the battery, causing it to swell, leak, or even burst. Additionally, physical damage to the battery, such as punctures or

Get a quote

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

The cooling air volume of a single rack should be equal to or greater than 1280m3/h. This ensures adequate airflow across the battery modules, which aids in heat dissipation and

Get a quote

UPS Room Requirements & Cooling Guide

A UPS requires a stable environment to operate efficiently and prolong battery life. Key considerations include: Ventilation: Ensure adequate airflow to

Get a quote

Best Practices and Considerations for Siting Battery Storage

Manufacturer performance warranties require that batteries operate in low temperatures and have access to adequate cooling and ventilation to avoid overheating, if they are located indoors. •

Get a quote

1635-2018

Ventilation of stationary battery installations is critical to improving battery life while reducing the hazards associated with hydrogen production. This guide describes battery

Get a quote

UPS & Battery Room Cooling | PDF | Rechargeable

1) The document discusses ventilation and cooling recommendations for UPS and battery rooms in data centers. Maintaining the proper temperature and

Get a quote

Checklist: Venting Clearance and Code Rules for Battery Cabinets

Stop battery overheating. This checklist details essential venting clearance and code rules for safe, compliant battery cabinet installation.

Get a quote

6 FAQs about [Battery cabinet installation heat dissipation requirements]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Do battery rooms need ventilation and temperature maintenance?

Battery Rooms require ventilation and a maintained temperature range. How can the ventilation rate and temperature maintenance be designed to the optimum? The paper proposes the minimum performance requirements for the temperature range and ventilation of rooms containing the batteries supporting Uninterruptible Power Supply (UPS) systems.

What are the requirements for a stationary battery ventilation system?

Ventilation systems for stationary batteries must address human health and safety, fire safety, equipment reliability and safety, as well as human comfort. The ventilation system must prevent the accumulation of hydrogen pockets greater than 1% concentration.

What are the requirements for a battery installation?

1. Space Planning and Layout 900mm min Battery Room Layout 1200mm Primary Access End Access 1000mm Battery Racks Industrial battery installations require adequate spacing for maintenance, ventilation, and safety. The layout should accommodate: 2. Structural Requirements

Do stationary battery installations need ventilation?

Ventilation of stationary battery installations is critical to improving battery life while reducing the hazards associated with hydrogen production. This guide describes battery operating modes and the hazards associated with each. It provides the HVAC designer with the information to provide a cost effective ventilation solution.

What are the requirements for a lead-acid battery ventilation system?

The ventilation system must prevent the accumulation of hydrogen pockets greater than 1% concentration. Flooded lead-acid batteries must be provided with a dedicated ventilation system that exhausts outdoors and prevents circulation of air in other parts of the building.

Guess what you want to know

-

New energy battery cabinet heat dissipation natural cooling

New energy battery cabinet heat dissipation natural cooling

-

Battery cabinet large battery installation

Battery cabinet large battery installation

-

National standard requirements for battery cabinet storage

National standard requirements for battery cabinet storage

-

Energy storage cabinet battery installation equipment base station

Energy storage cabinet battery installation equipment base station

-

Syria new energy battery cabinet installation

Syria new energy battery cabinet installation

-

Installation site of integrated battery cabinet

Installation site of integrated battery cabinet

-

Energy storage cabinet installation battery cabinet site

Energy storage cabinet installation battery cabinet site

-

Substation battery cabinet installation site

Substation battery cabinet installation site

-

Seychelles Outdoor Communication Battery Cabinet Installation Company Ranking

Seychelles Outdoor Communication Battery Cabinet Installation Company Ranking

-

Price query for outdoor communication battery cabinet installation in Brazil

Price query for outdoor communication battery cabinet installation in Brazil

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

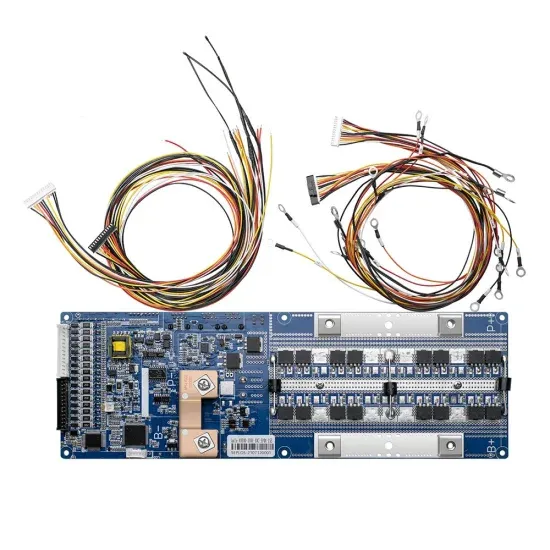

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.