480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get a quote

NFPA 70 and NFPA 70E Battery-Related Codes Update

Abstract Two code documents have a dramatic impact on the acceptance or rejection of a battery installation by an inspector. These are the National Electrical Code (NEC /NFPA 70 )1 and the

Get a quote

Codes & Standards Draft – Energy Storage Safety

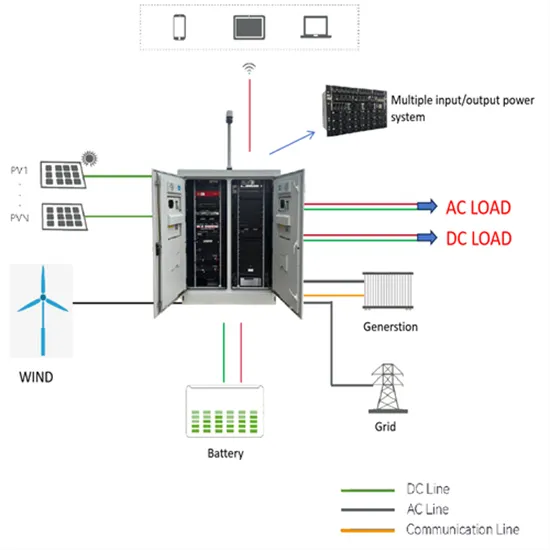

Covers requirements for battery systems as defined by this standard for use as energy storage for stationary applications such as for PV, wind turbine storage or for UPS, etc. applications.

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.)

Get a quote

Your Guide to Battery Energy Storage Regulatory Compliance

NFPA standards: The NFPA has specific standards for BESS, including NFPA 855 and NFPA 70, which address fire safety, installation and operation. Other standards: There are several other

Get a quote

Understand the codes, standards for battery energy storage systems

Understand the key differences and applications battery energy storage system (BESS) in buildings. Learn to navigate industry codes and standards for BESS design.

Get a quote

OSHA Standards in the Battery Room — Part Three:

The third blog in this series discusses OSHA safety regulations for General Industry (Part 1910) as it relates to electric forklift battery handling.

Get a quote

U.S. Codes and Standards for Battery Energy Storage Systems

This document provides an overview of current codes and standards (C+S) applicable to U.S. installations of utility-scale battery energy storage systems. This overview highlights the most

Get a quote

Battery Energy Storage System Installation requirements

This standard places restrictions on where a battery energy storage system (BESS) can be located and places restrictions on other equipment located in close proximity to the BESS. As

Get a quote

national standards for container energy storage cabinets

Considerations for Government Partners on Energy Storage shipping containers, outdoor-rated cabinets, or purpose-built buildings designed to safely house and maintain these batteries. •

Get a quote

Complying With Fire Codes Governing Lithium-ion Battery Use

In recent years, companies have adopted lithium-ion battery energy storage systems (BESS) which provide an essential source of backup transitional power. UL and governing bodies have

Get a quote

Maintaining Compliance in the VRLA Battery Room

Abstract Changes in Battery room regulation with International Building Code (IBC), Fire Code (IFC and NFPA), OSHA and best practices with IEEE have left questions on how to maintain

Get a quote

The Evolution of Battery Energy Storage Safety Codes and

This document explores the evolution of safety codes and standards for battery energy storage systems, focusing on key developments and implications.

Get a quote

Battery Storage Industry Unveils National Blueprint for Safety

ACP''s Utility-Scale Battery Energy Storage Systems Model Ordinance was designed with NFPA 855 as the core principle and integrates the national safety standard''s

Get a quote

A Comprehensive Guide: U.S. Codes and Standards for

NFPA 110 – The NFPA standard for emergency and standby power systems. The purpose of this standard is to provide requirements for the proper installation and maintenance of emergency

Get a quote

Understand the codes, standards for battery energy

Understand the key differences and applications battery energy storage system (BESS) in buildings. Learn to navigate industry codes and

Get a quote

Updated Codes and Standards for Stationary Batteries: White

These requirements cover battery chargers rated 600 volts or less and intended for household or commercial use to charge lead-acid engine-starter and other starting, lighting, and ignition

Get a quote

2018 Title Contents

This paper addresses the minimum requirements from Local, State and Federal requirements and historical trends in various areas where local AHJs have changed requirements in their

Get a quote

UL 9540A Test Method for Battery Energy Storage

UL 9540A, the Standard for Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems, is the American and

Get a quote

1926.441

Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or

Get a quote

6 FAQs about [National standard requirements for battery cabinet storage]

What is a battery standard?

Covers requirements for battery systems as defined by this standard for use as energy storage for stationary applications such as for PV, wind turbine storage or for UPS, etc. applications.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

What is a battery management standard?

A new standard that will apply to the design, performance, and safety of battery management systems. It includes use in several application areas, including stationary batteries installed in local energy storage, smart grids and auxillary power systems, as well as mobile batteries used in electric vehicles (EV), rail transport and aeronautics.

Do you need documentation before entering a battery room?

It is a requirement to have all the documentation in place prior to authorized personnel entering a battery room to perform a specific work task on a battery system under normal operating conditions. However, it is likely the employee will need to enter the battery room to deal with a battery system that is not operating normally.

What are the requirements for a battery handling facility?

Floors shall be of acid resistant construction unless protected from acid accumulations. Face shields, aprons, and rubber gloves shall be provided for workers handling acids or batteries. Facilities for quick drenching of the eyes and body shall be provided within 25 feet (7.62 m) of battery handling areas.

Guess what you want to know

-

Vaduz outdoor communication battery cabinet national standard

Vaduz outdoor communication battery cabinet national standard

-

National standard for 40-cell battery cabinet

National standard for 40-cell battery cabinet

-

New national standard photovoltaic communication battery cabinet

New national standard photovoltaic communication battery cabinet

-

Price of energy storage standard battery cabinet

Price of energy storage standard battery cabinet

-

What is the normal current of a 9v battery in an energy storage cabinet

What is the normal current of a 9v battery in an energy storage cabinet

-

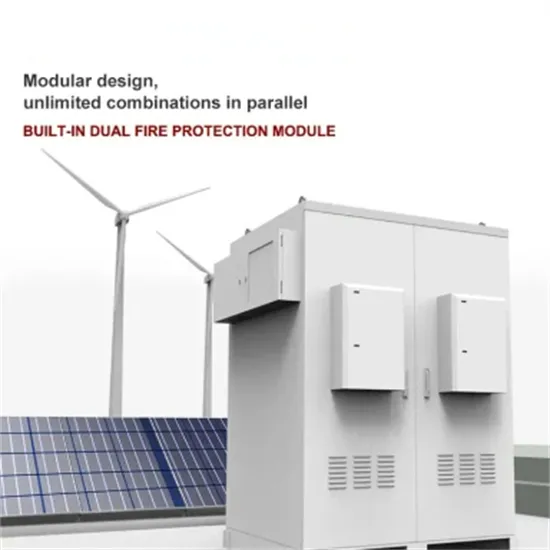

Fire protection design scheme for energy storage battery cabinet

Fire protection design scheme for energy storage battery cabinet

-

Hungary photovoltaic energy storage cabinet battery factory base station

Hungary photovoltaic energy storage cabinet battery factory base station

-

Lithium iron phosphate cabinet battery energy storage

Lithium iron phosphate cabinet battery energy storage

-

Georgia lithium battery energy storage cabinet energy

Georgia lithium battery energy storage cabinet energy

-

Iraq Energy Storage Cabinet Battery Department

Iraq Energy Storage Cabinet Battery Department

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.