2018 Title Contents

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards

Get a quote

NEMA 4 | Battery Enclosures | Hardcraft

From Pole-Mount Solutions to Very Large Battery Farms, Hardcraft''s State of the Art Battery Enclosures with Optional Climate and Hydrogen Control Features Lead the Industry for

Get a quote

What are the OSHA Requirements for Battery Storage (2023)

What are the OSHA Requirements for Battery Storage (2023) Last Updated: 16 October 2023 OSHA requirements for battery storage are essential for workplace safety.

Get a quote

NFPA 72 Battery Testing | National Training Center

With the cell/unit voltage test, we are going to leave the batteries connected to the panel and charger and measure the voltage of each battery individually, which

Get a quote

Industry safety codes and standards for energy

The safety of an energy storage system doesn''t have to be a guessing game. Both customers and installers can take comfort by choosing

Get a quote

Do Lithium Ion Batteries Require A Battery Room? Storage

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Get a quote

Battery Room Ventilation and Safety

Battery manufacturers use a standard method to determine how to rate their batteries. Their rating is based on tests performed over 20 hours with a discharge rate of 1/20 (5%) of the expected

Get a quote

New UL Standard Published: UL 1487, Battery Containment

The first edition of UL 1487, the Standard for Battery Containment Enclosures, was published on February 10, 2025, by UL Standards & Engagement as a binational standard for the United

Get a quote

Battery Room Design Requirements – PAKTECHPOINT

This is about design requirements for vented lead acid batteries, battery rooms and battery installations in main and unit substations and electrical equipment

Get a quote

Uninterruptible Power Supply (UPS) Backup Battery

Arimon offers several standard monobloc or top terminal battery cabinet sizes for 10 kVA to 125 kVA UPS systems accommodating monobloc batteries from 100

Get a quote

Eaton battery solutions brochure

This welded cabinet offers flexibility in adding runtime with a small footprint addition to the overall system. The 1085 model cabinets can support Eaton, CSB, Enersys, North-star, and Yuasa

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get a quote

Battery Cabinet

For a UPS system that does not ground the DC/Battery Circuit, isolation should be maintained between the chassis and any point in the battery circuit, to reduce the risk of electric shock

Get a quote

2018 International Solar Energy Provisions (ISEP)

The ISEP meets the industry''s need for a resource that contains the complete solar energy-related provisions from the 2018 International Codes and NFPA 70: 2017 NEC® National

Get a quote

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.)

Get a quote

Laurie Proof

As a result, a small contaminant in the cell introduced during production could result in the potential for catastrophic Feld failures. This realisation drove the industry and standards

Get a quote

The NEC and Storage Batteries | EC&M

The NEC and Storage Batteries Code rules for battery installations provide a critical part of what you need to know for a safe and reliable installation.

Get a quote

1926.441

Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or

Get a quote

Battery Room Design Requirements – PAKTECHPOINT

This is about design requirements for vented lead acid batteries, battery rooms and battery installations in main and unit substations and electrical equipment rooms.

Get a quote

6 FAQs about [National standard for 40-cell battery cabinet]

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What is a standard in battery testing?

In layman's terms, a standard provides minimum requirements and/or instructions in agreement within the industry for common reference. Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE).

What are the code rules for battery installations?

Code rules for battery installations provide a critical part of what you need to know for a safe and reliable installation. Article 480 provides the electrical installation requirements for all stationary installations of electrical storage batteries (Photo).

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

Does a battery room cover maintenance free or computer room type batteries?

It does not cover maintenance free or computer room type batteries and battery cabinets. Main keywords for this article are Battery Room Design Requirements, vented lead acid batteries, battery room safety requirements, Battery Room Ventilation, unit substations electrical. Batteries can be hazardous to both personnel and equipment.

Guess what you want to know

-

Vaduz outdoor communication battery cabinet national standard

Vaduz outdoor communication battery cabinet national standard

-

New national standard photovoltaic communication battery cabinet

New national standard photovoltaic communication battery cabinet

-

Battery cabinet dimensions width length and height standard

Battery cabinet dimensions width length and height standard

-

Where to buy 40-cell battery cabinet

Where to buy 40-cell battery cabinet

-

National Standard for Modular Battery Cabinets

National Standard for Modular Battery Cabinets

-

Standard Battery Cabinet Multiple

Standard Battery Cabinet Multiple

-

Battery energy storage cabinet explosion-proof standard price

Battery energy storage cabinet explosion-proof standard price

-

European German Battery Cabinet Factory Energy

European German Battery Cabinet Factory Energy

-

Senegal outdoor communication battery cabinet enterprise ranking

Senegal outdoor communication battery cabinet enterprise ranking

-

800900 Battery Cabinet

800900 Battery Cabinet

Industrial & Commercial Energy Storage Market Growth

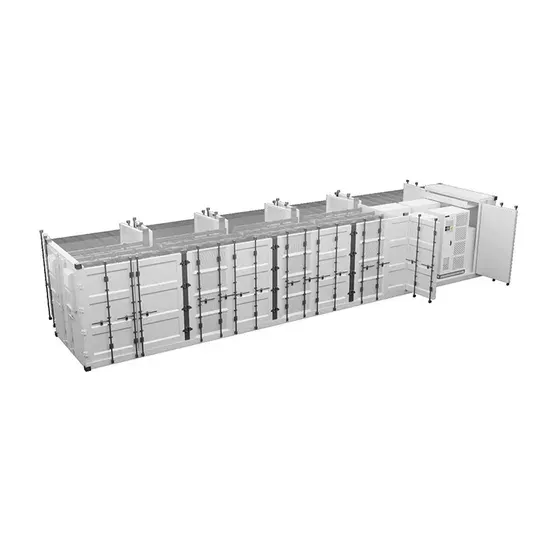

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.