Seismic Relay Racks and SCADA Enclosures | Hardcraft

Hardcraft designs and builds premium Distribution, Substation, and Baggage Inspection solutions for customers across the North America and around the world. Our work isn''t done until you''re

Get a quote

Substation Power Systems and Switchgear

Our national footprint and local service groups support the installation, maintenance and end-of-life recycling processes for turn-key switchgear,

Get a quote

UPS / DC Equipment and Battery Rack, Installation and

This article is about UPS / DC Equipment and Battery Rack, Installation and Pre-Commissioning & Requirements of Electrical Power System Systems as per International Codes and

Get a quote

ECO ESS-Outdoor cabinet energy storage system

5.1 fixing of outdoor energy storage cabinet Before fixing the outdoor energy storage cabinet, please recheck whether the outdoor energy storage cabinet is placed in a qualified position

Get a quote

-48 VDC Battery Cabinet Installation and User Manual

Install the frame ground landing point adapter P/N 556872 to the left or right side of the battery cabinet, as shown in Figure 5. Installing P/N 556872 Frame Ground Landing Point Adapter

Get a quote

NASS | Transformer & Substation Experts | A Voltyx Company

NASS: Nationally-recognized experts specializing in Transformer & Substation Apparatus Installation, Services, & Repair.

Get a quote

Substations Design, Construction and Installation

BEI Construction has been involved in over 2.4GW battery storage, solar, substations, wind, and EV charging projects. Our renewable energy systems

Get a quote

Powering Up Safely: The Ins and Outs of Substation Battery

In this guide, we break down the essential role of substation battery systems, best practices for installation, the importance of regular maintenance, and what to watch for to

Get a quote

WORKING DRAFT XDS-GFS-09-001-R4-Last version

1 SCOPE This functional specification outlines the requirements for the supply, manufacturing and testing of vented-type Planté lead-acid batteries, battery chargers, battery stands,

Get a quote

Fundamentals of Modern Electrical Substations

Part 1 of this course series is concentrated on demonstrating how modern power systems are arranged to accomplish all these goals; what place electrical substations have in the overall

Get a quote

Indoor and Outdoor Battery Cabinet Systems

Outdoor battery cabinets are an easy way to add a new DC system to older substations where room in the control house is limited. This allows for a back-up power source for control

Get a quote

Substations Design, Construction and Installation

BEI Construction has been involved in over 2.4GW battery storage, solar, substations, wind, and EV charging projects. Our renewable energy systems use the latest technologies and

Get a quote

Maintenance BestPractices & Intervals for Substation

Maintenance BestPractices & Intervals for Substation Equipment Presented by: Paul Schlies, President/CEO Energis High Voltage Services, Inc.

Get a quote

UPS / DC Equipment and Battery Rack, Installation

This article is about UPS / DC Equipment and Battery Rack, Installation and Pre-Commissioning & Requirements of Electrical Power System Systems as per

Get a quote

Building and Maintaining a Safe Substation Battery System

The working space from the front of the batteries should be measured from the farthest protrusion from the battery equipment. Most of the time this will be the battery drip pan

Get a quote

Battery Room Design Requirements – PAKTECHPOINT

This article will give you an overall introduction to substation cabinets and how to use it properly, also the precautions tips on the

Get a quote

Four Overlooked BESS Project Requirements

From substations to hybrid renewable sites, energy infrastructure that plans to include an AC-coupled battery energy storage system (BESS) can be surprisingly complex

Get a quote

DC Battery Rack Grounding

In my years as a substation electrician we never grounded battery racks. All substations I''m familiar with have ungrounded DC because a ground fault on either polarity will

Get a quote

Battery Room Design Requirements – PAKTECHPOINT

This is about design requirements for vented lead acid batteries, battery rooms and battery installations in main and unit substations and electrical equipment rooms.

Get a quote

Turnkey Substation Control Centers

DC panelboards and DC distribution wiring DC battery systems including charger, rack, spill containment, and batteries Termination cabinets (indoor and outdoor) or pull boxes Keystone

Get a quote

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

For instance, if a battery, rack and charger are required the system can be designed using a 2 step rack with the charger mounted above, or with a 2-tier rack with the charger mounted to

Get a quote

Building and Maintaining a Safe Substation Battery

The working space from the front of the batteries should be measured from the farthest protrusion from the battery equipment. Most of the

Get a quote

Substation DC Auxiliary Supply – Battery And Charger

Figure 1 – Typical single-battery and charger application In a typical installation, especially with batteries of considerable size, the batteries are installed in a separate battery room. The

Get a quote

Powering Up Safely: The Ins and Outs of Substation Battery Installation

In this guide, we break down the essential role of substation battery systems, best practices for installation, the importance of regular maintenance, and what to watch for to

Get a quote

Substation Power Systems and Switchgear

Our national footprint and local service groups support the installation, maintenance and end-of-life recycling processes for turn-key switchgear, control and power generation support. Power

Get a quote

Indoor and Outdoor Battery Cabinet Systems

Outdoor battery cabinets are an easy way to add a new DC system to older substations where room in the control house is limited. This allows for a back

Get a quote

6 FAQs about [Substation battery cabinet installation site]

Where should batteries be installed in a substation?

Batteries installed in unit substations, electrical equipment rooms and instrument rack rooms shall comply with the requirements of this section, Main Substation Design and Unit Substation Design. In these locations, stainless steel hoods vented to the outside shall be installed over batteries.

What are the requirements for a substation battery system?

Substation battery systems shall be dedicated to connected DC load and shall not be part of a plant UPS or other DC system. Working space of at least 1 meter shall be provided in front of each battery rack or enclosure. Batteries shall be supplied with covers for all inter-cell connecters and terminals or insulated copper busbars to enhance safety.

What issues should a substation design engineer consider when installing batteries?

Hydrogen off-gassing is another issue that often arises when dealing with batteries in a substation. The design engineer should consult American Petroleum Institute Recommended Practice 500 to determine ventilation and classification requirements whenever batteries are installed indoors.

What is a petrochemical substation?

Substations are prevalent in all petrochemical facilities. Their function is to distribute power to the process units. Typically, there are either one or two types of battery systems within each substation. There may be a “station power” battery system to power the switchgear controls, which typically operates at 125VDC.

Why do substations need reliable energy storage solutions?

With the power utility landscape changing in terms of both architecture and methods of generation, the need for reliable energy storage solutions is growing. Substations are evolving and adapting to support new and varied generation sources including renewables.

Where should a stationary battery be installed?

Stationary batteries shall be installed on open battery racks within a battery room to facilitate proper cooling, routine inspection, and maintenance. Covers for all inter-cell connecters and battery terminals or insulated copper busbars shall be supplied as part of the battery to enhance safety.

Guess what you want to know

-

Outdoor air-cooled battery cabinet installation site

Outdoor air-cooled battery cabinet installation site

-

Installation site of integrated battery cabinet

Installation site of integrated battery cabinet

-

Photovoltaic communication battery energy storage cabinet installation site

Photovoltaic communication battery energy storage cabinet installation site

-

Energy storage cabinet battery liquid cooling installation site

Energy storage cabinet battery liquid cooling installation site

-

Price query for outdoor communication battery cabinet installation in Brazil

Price query for outdoor communication battery cabinet installation in Brazil

-

Communication network cabinet lithium battery site cabinet solution

Communication network cabinet lithium battery site cabinet solution

-

Telecom site with battery cabinet base station power

Telecom site with battery cabinet base station power

-

What should I do when replacing the new battery cabinet at the telecom site

What should I do when replacing the new battery cabinet at the telecom site

-

Lithium battery site cabinet base station energy composition

Lithium battery site cabinet base station energy composition

-

South Africa site energy battery cabinet brand ranking

South Africa site energy battery cabinet brand ranking

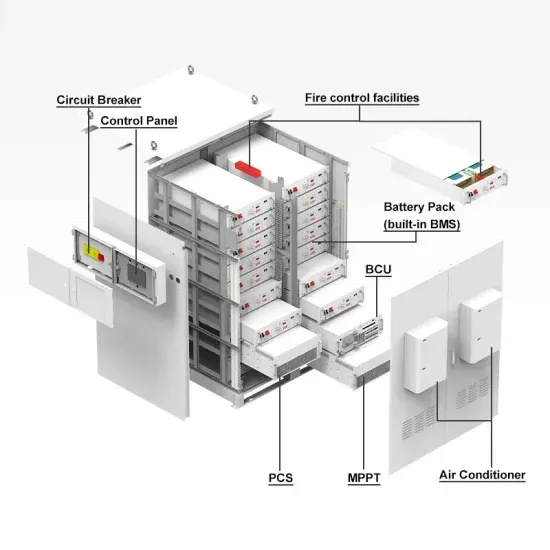

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

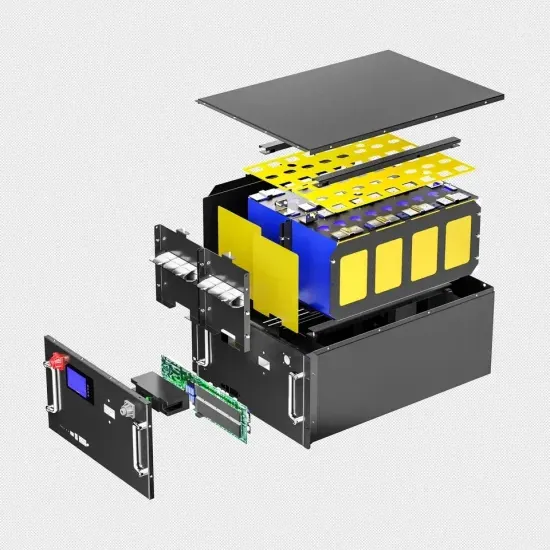

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.