What Is a BMS in Batteries? Definition, Functions, and

A Battery Management System (BMS) is the intelligent controller that ensures batteries are used safely, efficiently, and reliably. Whether you''re

Get a quote

Battery Management System Hardware Concepts: An Overview

This paper focuses on the hardware aspects of battery management systems (BMS) for electric vehicle and stationary applications. The purpose is giving an overview on existing concepts in

Get a quote

Understanding Battery Management Systems: The Key to

Exencell, as a leader in the high-end energy storage battery market, has always been committed to providing clean and green energy to our global partners, continuously

Get a quote

Battery Management System (BMS) | GERCHAMP

This article will explore the basic composition and working principles of the BMS structure and analyze its key role in battery management. Basic Composition of BMS Structure

Get a quote

Battery Management Systems (BMS): A Complete Guide

In this article, we will discuss battery management systems, their purpose, architecture, design considerations for BMS, and future trends. Ask

Get a quote

Battery Management System: Components, Types

Learn the basics of Battery Management Systems (BMS), improving battery performance, safety, and longevity in EVs, renewable energy, and more.

Get a quote

A Detailed Schematic of a Battery Management System

Discover the key components and layout of a battery management system schematic for effective control and monitoring of battery packs in various

Get a quote

Battery Management System: Components, Types and Objectives

Learn the basics of Battery Management Systems (BMS), improving battery performance, safety, and longevity in EVs, renewable energy, and more.

Get a quote

Battery Management System | Schaeffler Germany

The BMS consists of Battery Management Controller (BMC), Cell Supervising Circuits (CSCs) and Battery Junction Box (BJB). Functions include functional safety, determination of State of

Get a quote

Components of Battery Management System for Li-ion battery

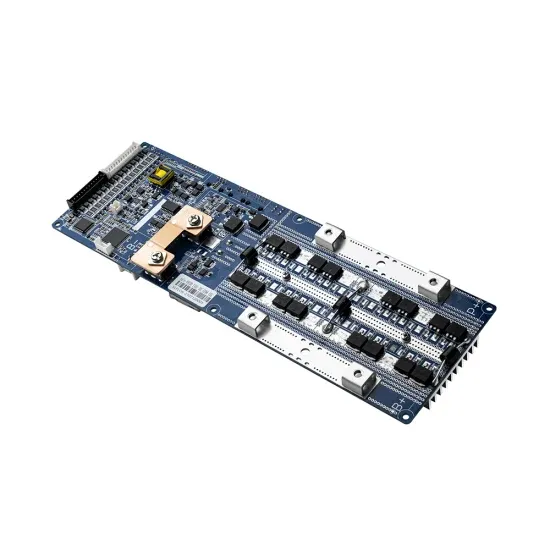

Let us understand the key components of battery management system, different parts of battery management system, and battery management system architecture diagram.

Get a quote

Introduction to Battery Management Systems

In this article, we''ll discuss the basics of the BMS concept and go over a few foundational parts that make up the typical BMS. In Figure 1, we see the basic blocks of how a

Get a quote

Introduction to Battery Management Systems

This article will explore the basic composition and working principles of the BMS structure and analyze its key role in battery management. Basic Composition of BMS Structure

Get a quote

Understand the BMS Components and Functions

In this blog, we''ll briefly introduce what battery management systems are, and explore the BMS components, and how they work to get the best performance from battery

Get a quote

Battery Management System (BMS) for Efficiency and Safety

Learn How Battery Management System (BMS) Optimizes Efficiency and Safety in Electric Vehicles, Energy Storage, and Electronics.

Get a quote

Battery management system

A battery management system (BMS) is any electronic system that manages a rechargeable battery (cell or battery pack) by facilitating the safe usage and a long life of the battery in

Get a quote

Battery Management Systems (BMS)

A Battery Management System (BMS) is an electronic system that manages and monitors rechargeable batteries, ensuring their safe and eficient operation. It consists of hardware and

Get a quote

Battery Management System (BMS) Architecture: A

In modern electric vehicles (EVs), the Battery Management System (BMS) is a critical component that ensures the safety, reliability, and

Get a quote

foxBMS – The Most Advanced Open Source BMS

Overview foxBMS is a free, open and flexible research and development environment for the design of Battery Management Systems (BMS). Above all,

Get a quote

How Battery Management Systems Operate and Their Essential

Controllers and microprocessors act as the decision-making hub of a BMS. They process data collected by sensors to evaluate the battery''s health and remaining charge.

Get a quote

Understanding the Battery Management System

Understanding Battery Management Systems A BMS is an electronic system that oversees and controls the charging and discharging of rechargeable batteries. The primary objective of a

Get a quote

Battery Management Systems (BMS): A Complete Guide

In this article, we will discuss battery management systems, their purpose, architecture, design considerations for BMS, and future trends. Ask questions if you have any

Get a quote

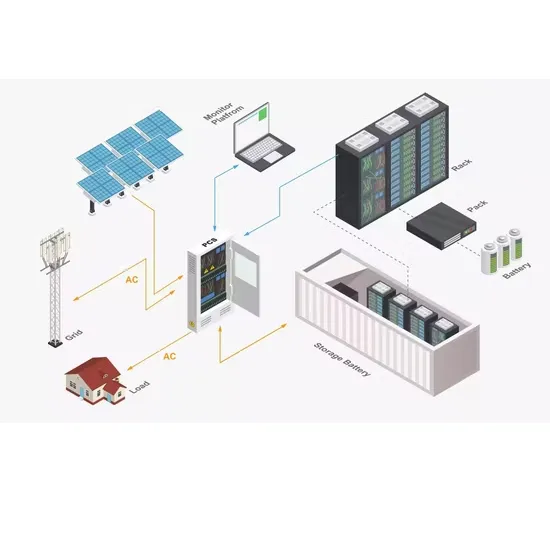

Battery Energy Storage System Components and

These are battery and battery management system (BMS), inverter or power conversion systems (PCS), energy management system (EMS) and

Get a quote

Battery Management System (BMS) Architecture: A Technical

In modern electric vehicles (EVs), the Battery Management System (BMS) is a critical component that ensures the safety, reliability, and performance of the battery pack. The

Get a quote

6 FAQs about [Components of the German BMS battery management system]

What are the components of a battery management system (BMS)?

A typical BMS consists of: Battery Management Controller (BMC): The brain of the BMS, processing real-time data. Voltage and Current Sensors: Measures cell voltage and current. Temperature Sensors: Monitor heat variations. Balancing Circuit: Ensures uniform charge distribution. Power Supply Unit: Provides energy to the BMS components.

What is a BMS control unit?

The control unit processes data collected from the battery and ensures that the system operates within its safe operating area. A critical part of the BMS, this system uses air cooling or liquid cooling to maintain the temperature of the battery cells.

What is a BMS structure?

The basic composition and working principles of the BMS structure are closely related, working together to ensure the efficiency, safety, and longevity of battery systems. With the development of battery technology, the BMS structure will continue to play a crucial role in the field of battery applications.

What are the components of BMS architecture?

Key Components of the BMS Architecture Li-ion Cells (Battery Cells): The foundation of the system consists of lithium-ion cells that form the battery pack. These cells are arranged in series or parallel configurations depending on the desired voltage and capacity.

What are the different types of battery management systems?

There are two primary types of battery management systems based on their design and architecture: Features a single control unit managing the entire battery pack. Simplifies data collection and control but may face scalability challenges for larger systems. Employs a modular architecture where smaller BMS units manage groups of battery cells.

What makes a good battery management system?

A BMS must be designed for specific battery chemistries such as: 02. Power Consumption: An efficient BMS should consume minimal power to prevent draining the battery unnecessarily. 03. Scalability: For large-scale applications (EVs, grid storage), a scalable BMS is essential.

Guess what you want to know

-

BMS battery management system replacement

BMS battery management system replacement

-

Palestine BMS Battery Management Control System

Palestine BMS Battery Management Control System

-

The role of Fiji BMS battery management power system

The role of Fiji BMS battery management power system

-

Libya BMS battery management power system architecture

Libya BMS battery management power system architecture

-

Lifeng BMS battery management system

Lifeng BMS battery management system

-

Chilean Battery Management System BMS

Chilean Battery Management System BMS

-

How does BMS battery management communicate

How does BMS battery management communicate

-

Silicon Carbide BMS Battery Management

Silicon Carbide BMS Battery Management

-

BMS battery management system assembly

BMS battery management system assembly

-

Portable outdoor battery cabinet BMS battery management

Portable outdoor battery cabinet BMS battery management

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.