Silicon Carbide in Developing Next-Gen Li-ion Batteries

Researchers and manufacturers can incorporate Silicon Carbide into Li-ion batteries without requiring significant changes to the existing production

Get a quote

Ref: ONSAR3160 Enhancing Battery Energy Storage

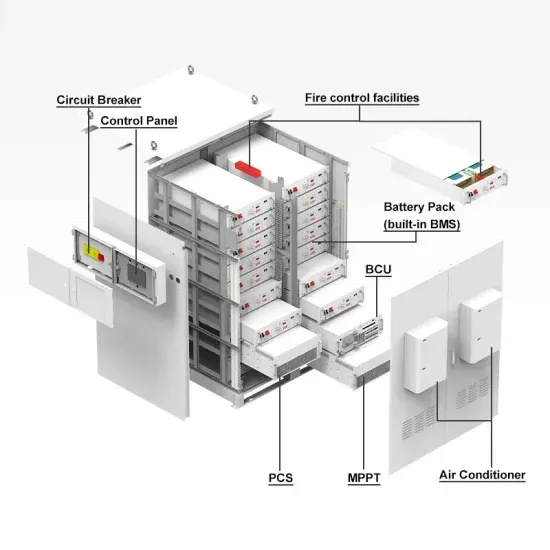

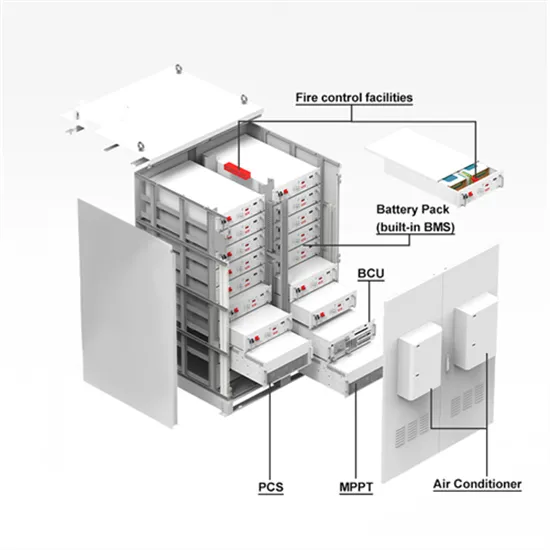

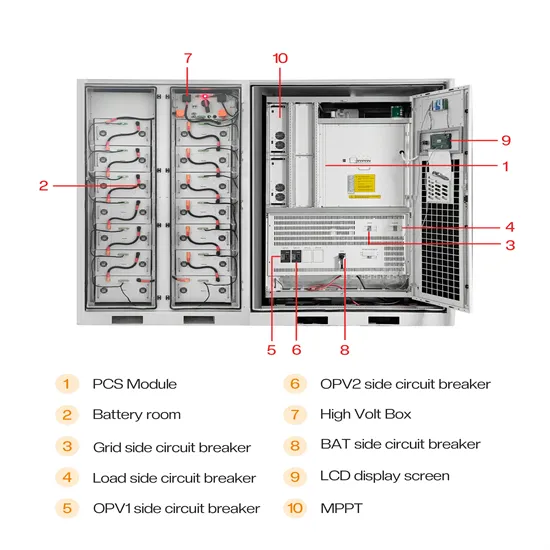

Rechargeable battery module: This comprises rack-mounted battery cells with nominal voltage ranging from 50 V to over 1000 V. Battery management system (BMS): The BMS protects and

Get a quote

Enhance Efficiency in Battery Energy Storage Systems with

Discover how Silicon Carbide (SiC) can improve efficiency, reduce costs, and enhance performance in Battery Energy Storage Systems (BESS). Learn about the

Get a quote

It is in the batteries, however, where significant room for improvement lies. Part of this has to do with the composition of the battery cells themselves, an area that has seen leaps and bounds

Get a quote

Battery Management System (BMS): Diagrams & IC Selection

Key Functions of a Battery Management System (BMS) The core function of a BMS (Battery Management System) in electric vehicles is to coordinate five roles that together

Get a quote

Electric Vehicle BMS Drives a Third of Silicon Demand

But IDTechEx''s " Semiconductors for Autonomous and Electric Vehicles 2023-2033 " report goes down to the level of individual chips and wafers. From this perspective, the

Get a quote

HVDC POWER DISTRIBUTION AND CONVERSION

In this paper we present three enabling technologies developed by Creare: (1) an intelligent Battery Management System (BMS); (2) a fast-acting Silicon Carbide (SiC) SSCB; and (3) an

Get a quote

Silicon Carbide for the Success of Electric Vehicles

Here, silicon carbide may make sense, because the efficiency gains allow use of a smaller battery, and therefore, I can compensate for the

Get a quote

The key to long-range EVs: Opto-SiC MOSFET

These battery packs are composed of many battery cells. The oversight that a BMS provides includes Insulation Monitor and Detection, reporting operational

Get a quote

Enhance Efficiency in Battery Energy Storage Systems with Silicon Carbide

Discover how Silicon Carbide (SiC) can improve efficiency, reduce costs, and enhance performance in Battery Energy Storage Systems (BESS). Learn about the

Get a quote

Silicon Carbide BMS Battery Management

A battery management system (BMS) is a sophisticated control system that monitors and manages key parameters of a battery pack, such as battery status, cell voltage, state of

Get a quote

The key to long-range EVs: Opto-SiC MOSFET Relays applied on BMS

These battery packs are composed of many battery cells. The oversight that a BMS provides includes Insulation Monitor and Detection, reporting operational status, and continually

Get a quote

Silicon Carbide for the Success of Electric Vehicles

Battery management systems typically include five main circuit groups: OBC, BMS, DC/DC converter, and main inverter. The battery charger power blocks consist of an

Get a quote

Wolfspeed Silicon Carbide Companion Guide

Pair Wolfspeed Silicon Carbide Power Devices with Compatible Gate Drivers from Analog Devices Wolfspeed is the global leader in Silicon Carbide (SiC) wide bandgap semiconductor

Get a quote

Connector Solutions for EV BMS

In this talk you will learn about Amphenol''s solution for EV Battery Management Systems (BMS) and the need for efficient control and monitoring of an integrated battery system.

Get a quote

Silicon Carbide Power Switches Boost HEV Battery Management

Explore how silicon carbide power switches enhance efficiency and performance in hybrid electric vehicle battery management systems for sustainable mobility.

Get a quote

Diamond-Silicon Carbide Material for Next Generation Thermal Management

The patented diamond-silicon carbide material from Coherent achieves isotropic thermal conductivity exceeding 800 W/m-K, and delivers twice the performance of copper, the

Get a quote

Electric Vehicle Battery Management System (BMS) Drives a

IDTechEx''s research finds that, although power electronics are such a hefty set of components, the battery management system makes up approximately one-third of the silicon

Get a quote

NXPTechnology Batter y Management System

Last Updated: Dec 30, 2021 NXP''s scalable battery management system (BMS) can be used in industrial or automotive applications. The BMS offers high measurement accuracy after

Get a quote

Marelli Unveils New 800 V Silicon Carbide Inverter

Marelli''s Battery Management System (BMS) Just over a month before its release of these new inverters, Marelli also launched its wireless

Get a quote

Coto Announces New High-Voltage 1700V MOSFET

Coto Technology has announced the release of its new CotoMOS® S117X, a High-Voltage Silicon Carbide (SiC) MOSFET Relay. This cutting-edge relay is

Get a quote

Enhance Efficiency in Battery Energy Storage Systems with Silicon Carbide

Discover how Silicon Carbide (SiC) technology enhances energy storage systems (ESS) with improved reliability, efficiency, and sustainability in modern power systems.

Get a quote

Electric Vehicle Battery Management System (BMS) Drives a

But IDTechEx''s "Semiconductors for Autonomous and Electric Vehicles 2023-2033" report goes down to the level of individual chips and wafers. From this perspective, the

Get a quote

Infineon and Eatron extend collaboration for AI-powered battery

The technology integrates Eatron''s AI-powered BMS software with Infineon''s components including MOSFETs for battery protection and PSOC 6 AI-based battery management system

Get a quote

Infineon, Eatron Expand Partnership for AI-Powered

Infineon''s PSOC microcontrollers enable AI-driven battery optimization, enhancing safety, performance, and reliability. MUNICH,

Get a quote

Enhance Efficiency in Battery Energy Storage

Discover how Silicon Carbide (SiC) technology enhances energy storage systems (ESS) with improved reliability, efficiency, and sustainability

Get a quote

Electric Vehicle Battery Management System (BMS)

IDTechEx''s research finds that, although power electronics are such a hefty set of components, the battery management system makes up

Get a quote

3 FAQs about [Silicon Carbide BMS Battery Management]

What is silicon carbide (SiC) in battery energy storage systems?

Discover how Silicon Carbide (SiC) can improve efficiency, reduce costs, and enhance performance in Battery Energy Storage Systems (BESS). Learn about the advantages of SiC in ESS design, including bidirectional power flow, lower conduction losses, and compact, cost-effective designs.

How to ensure long-term reliability of a battery?

Selecting a technology with high energy density and efficiency is essential. However, batteries degrade over time due to chemical reactions during charge and discharge cycles. Ensuring long-term reliability involves managing this degradation and implementing strategies to extend battery life.

Why are sic devices better than MOSFETs & IGBTs?

SiC devices feature a body diode with low reverse recovery charge, a critical property for reducing losses during high-frequency switching. This makes SiC superior to Si-based MOSFETs and IGBTs, where reverse recovery losses are higher, leading to reduced efficiency in such topologies.

Guess what you want to know

-

Luxembourg Battery Management System BMS

Luxembourg Battery Management System BMS

-

Is BMS battery management useful

Is BMS battery management useful

-

Taipei BMS Battery Management Control System

Taipei BMS Battery Management Control System

-

Lesotho BMS battery management control system brand

Lesotho BMS battery management control system brand

-

High-tech BMS battery management control system

High-tech BMS battery management control system

-

Palestine BMS Battery Management Control System

Palestine BMS Battery Management Control System

-

Lost communication with the BMS battery management system

Lost communication with the BMS battery management system

-

Sofia BMS battery management system manufacturer

Sofia BMS battery management system manufacturer

-

Lithuanian BMS battery management power system brand

Lithuanian BMS battery management power system brand

-

The role of Fiji BMS battery management power system

The role of Fiji BMS battery management power system

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.