Special Report on Solar PV Global Supply Chains

This special report examines solar PV supply chains from raw materials all the way to the finished product, spanning the five main segments of the manufacturing process: polysilicon, ingots,

Get a quote

Thin prospects for ingot, wafer and solar cell manufacturing

Gleaming crystalline silicon ingots emerge from towering pullers to be sliced by diamond wire saws into iridescent, black square, or rectangular, monocrystalline wafers. The

Get a quote

What are the differences between single-glass and

As a high-quality manufacturer and supplier of Double Glass Solar Panels, solar modules, and Solar Panels, we provide you with high-quality

Get a quote

Monocrystalline solar panels: what you should know before buying

To make a solar panel monocrystalline cells are assembled together Once monocrystalline solar cells are manufactured, they can be connected with silver wires and

Get a quote

Single-glass versus double-glass: a deep dive into

The choice of glass in a PV module has become a key consideration in efforts to improve durability in the face of extreme weather

Get a quote

Monocrystalline Half-Cell Bifacial Double Glass Module Strategic

The monocrystalline half-cell bifacial double-glass module market is experiencing robust growth, driven by increasing demand for high-efficiency solar energy solutions. This

Get a quote

PowerPoint 演示文稿

Bifacial modules with frame can reduce module breakage rate during transportation and installation Bifacial modules with frame can save labor cost and are compatible with tracker

Get a quote

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that

Get a quote

The Difference Between Bifacial Module and Double

Bifacial solar modules and double glass bifacial solar modules are both types of solar panels designed to capture sunlight from both sides (front

Get a quote

Types of PV Panels – Solar Photovoltaic Technology

Monocrystalline semiconductor wafers are cut from single-crystal silicon ingots as opposed to multicrystsalline semiconductor wafers which are grown in thin

Get a quote

Double the strengths, double the benefits

Generally, the front and back glass layers in these modules have the same thickness, contributing to their balanced structural integrity. This

Get a quote

Types of PV Panels – Solar Photovoltaic Technology

Monocrystalline semiconductor wafers are cut from single-crystal silicon ingots as opposed to multicrystsalline semiconductor wafers which are grown in thin sheets or are cut from

Get a quote

Single-glass versus double-glass: a deep dive into module

The choice of glass in a PV module has become a key consideration in efforts to improve durability in the face of extreme weather conditions.

Get a quote

Photovoltaic (PV) Module Technologies: 2020 Benchmark

Notable features of high-performing monocrystalline modules include half-cut cells, busbarless cell metallization and interconnection, and glass-glass or glass-transparent backsheet bifacial

Get a quote

United States Monocrystalline Half-Cell Bifacial Double Glass Module

United States Monocrystalline Half-Cell Bifacial Double Glass Module Market: Key Highlights The U.S. market for monocrystalline half-cell bifacial double glass modules is

Get a quote

Glass-Glass PV Modules

Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures, humidity and

Get a quote

Cz Monocrystalline Silicon Production

One way to work around the segregation issue is the use of the Recharge Czochralski (RCz) ingot-pulling technique. The RCz technique is an innovative

Get a quote

Glass-Glass PV Modules

Double-glass modules boast increased reliability, especially for utility scale PV projects. These include better resistance to higher temperatures, humidity and UV conditions and have better

Get a quote

Dual-glass vs glass-backsheet: The winning formula for bifacial modules

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the

Get a quote

Material intensity and carbon footprint of crystalline silicon module

The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Get a quote

What are the differences between single-glass and double-glass

As a high-quality manufacturer and supplier of Double Glass Solar Panels, solar modules, and Solar Panels, we provide you with high-quality products and PV module

Get a quote

Silicon Solar Cells: Trends, Manufacturing

For solar cell applications, either SoG-Si or EG-Si feedstock is used to produce silicon ingots. For the growth of monocrystalline ingots, the

Get a quote

Module

Crystalline silicon PV module manufacturing involves multiple steps. First, polysilicon processing takes place. Once polysilicon is produced, it is formed into ingots, which are sliced into thin

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal

Get a quote

Double the strengths, double the benefits

Generally, the front and back glass layers in these modules have the same thickness, contributing to their balanced structural integrity. This design not only enhances the

Get a quote

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Get a quote

What is the Double Glass (Dual Glass) Photovoltaic

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the

Get a quote

What are Double Glass Solar Panels?

Double-glass solar modules are made up of two layers of tempered glass that cover both sides of the solar panel. As snow accumulates on a typical solar panel or people

Get a quote

6 FAQs about [Ingot monocrystalline and double-glass modules]

What is a dual glass module?

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the back glass with a unique drilling technique that ensures the reliability of both the junction box installation and the module.

Does Trina Solar have a dual glass bifacial module?

However, Trina Solar has made such a breakthrough by abandoning the backsheet and developing the brand-new dual glass module. Trina Solar Vertex TSM-DEG21C.20 (670 W) framed dual-glass bifacial module

What is the difference between Raytech double glass solar modules?

Whereas for Raytech double-glass solar modules, with the increased strength brought by two layers of glass, a lot less deformation will happen in the solar cells, the possibility of microcracks formed on the solar cells will decrease significantly.

Are double-glass solar modules reactive or non-reactive?

Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This means that the whole structure of Raytech double-glass solar modules (two layers of glass and one layer of solar cells in the middle) are highly resistant to chemical reactions such as corrosion as a whole.

What is tempered glass solar module?

Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and solar cells against physical stress, snow, wind, dust and moisture etc, at the same time guaranteeing that the sunlight can go in. The backside is generally protected by an opaque sheet called the backsheet.

How much power does a monocrystalline module use?

In 2019, typical 72-cell multicrystalline modules were rated at 320–350 W, whereas monocrystalline modules with half-cut cells were rated at 430–440 W. These trends may help explain the projected monocrystalline market share growing from 60% in 2019 to almost 90% by 2025 (ITRPV Working Group 2019).

Guess what you want to know

-

Monocrystalline silicon double-glass bifacial photovoltaic modules

Monocrystalline silicon double-glass bifacial photovoltaic modules

-

Monocrystalline p-type bifacial double-glass modules

Monocrystalline p-type bifacial double-glass modules

-

Monocrystalline single-sided double-glass modules

Monocrystalline single-sided double-glass modules

-

Price of monocrystalline photovoltaic modules

Price of monocrystalline photovoltaic modules

-

Huawei now has monocrystalline silicon photovoltaic modules

Huawei now has monocrystalline silicon photovoltaic modules

-

Main uses of double-glass modules

Main uses of double-glass modules

-

Double-glass multi-crystalline modules and multi-crystalline modules

Double-glass multi-crystalline modules and multi-crystalline modules

-

Double-sided double-glass 670 modules

Double-sided double-glass 670 modules

-

Structure of double-glass modules

Structure of double-glass modules

-

Huawei brand all-black double-glass modules

Huawei brand all-black double-glass modules

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

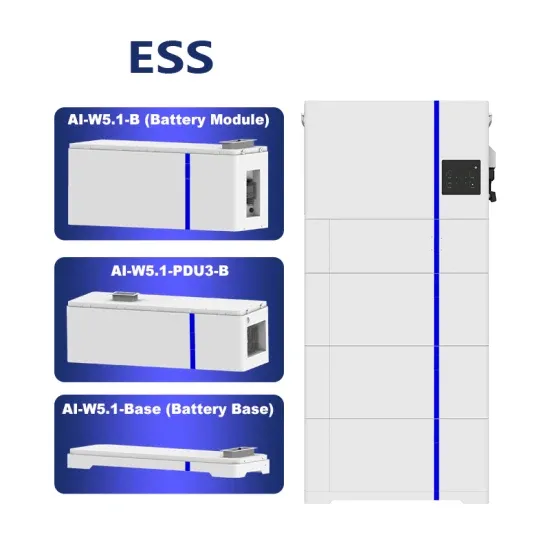

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.