7 Advantages of Bifacial Glass-Backsheet Modules

There are two common methods for making bifacial solar PV modules: The first involves using glass layers on both the front and rear sides

Get a quote

Dual-glass vs glass-backsheet: The winning formula

Bifacial glass technology is the preferred material among manufacturers for the rear side cover of the modules. Some key advantages

Get a quote

DOUBLE GLASS SOLAR MODULE

Are double-glass PV modules durable? Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this

Get a quote

Structure of double glass (a) and traditional module (b).

To systematically investigate the degradation behavior of double glass modules compared with traditional backsheet modules, we carried out an extensive

Get a quote

Presentation

6 Why are Glass-Glass Modules Appealing? Double glass construction is stronger and more durable Less prone to back side scratches Less prone to hot spot burns Modules less

Get a quote

Double the strengths, double the benefits

In contrast, double glass modules replace the polymer layer with another glass sheet, creating a robust sandwich structure. At IBC SOLAR, we use 2,0 mm x 2,0 mm glass

Get a quote

Structure of double glass (a) and traditional module (b).

To systematically investigate the degradation behavior of double glass modules compared with traditional backsheet modules, we carried out an extensive program with series sequential...

Get a quote

What is a double-sided double-glass photovoltaic module?

The structure of double-sided double-glass modules includes: double-layer glass + frameless structure; double-sided (with frame) modules adopt Transparent backplane + border

Get a quote

How does the double-glass design enhance the resistance to

By limiting moisture penetration, the double-glass design inhibits this ion migration, thereby lowering PID risk. Symmetrical structure and neutral mechanical stresses: In double

Get a quote

What are the advantages of dual-glass Dualsun modules?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

Get a quote

What is the Double Glass (Dual Glass) Photovoltaic

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the

Get a quote

JA Solar PV Bifacial Double-glass Modules

Modules have no on/off switch. Modules can be rendered inoperative only by removing them from sunlight, or by fully covering their front surface with cloth, cardboard, or other completely

Get a quote

Double-glass PV modules with silicone encapsulation

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In

Get a quote

High performance double-glass bifacial PV modules through

High performance double-glass bifacial PV modules through detailed characterization Yong Sheng Khoo, Jai Prakash Singh, Min Hsian Saw

Get a quote

2025 Complete Guide to Glass-Glass Solar Panels: The Top

Glass-glass PV modules, also known as double glass solar panels, are photovoltaic modules encapsulated with tempered glass on both the front and back sides. Compared to traditional

Get a quote

Experimental repair technique for glass defects of glass-glass

In double-glass or glass-glass PV modules the polymer back sheet layer is replaced by a glass layer identical to the top glass, creating a symmetrical "sandwich" structure.

Get a quote

Double-sided double-glass module structure

Double-glass solar modules are made up of two layers of tempered glass that cover both sides of the solar panel. As snow accumulates on a typical solar panel or people stomp on it (during

Get a quote

Comparison of Glass/Glass and Glass/Backsheet PV Modules Using Bifacial

Bifacial solar cells can be encapsulated in modules with either a glass/glass or a glass/backsheet structure. A glass/backsheet structure provides additional module current under standard test

Get a quote

2025 Complete Guide to Glass-Glass Solar Panels: The Top

What Are Glass-Glass PV Modules? Glass-glass PV modules, also known as double glass solar panels, are photovoltaic modules encapsulated with tempered glass on both the front and

Get a quote

Flexible vs. Rigid Double-Glass Solar Panels: Which One is Your

Compare flexible and rigid double-glass solar panels in terms of features, performance, and applications to find the best solution for your needs.

Get a quote

What is the difference between a double-sided double-glass n

The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Get a quote

INSTRUCTIONS FOR PREPARATION OF PAPERS

By choosing heat strengthened glass panels on both sides, we have been able to use a thickness of 2.5mm and to demonstrate an excellent module resistance to all standard mechanical tests

Get a quote

What is the Double Glass (Dual Glass) Photovoltaic Solar Panel?

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet.

Get a quote

2025 Complete Guide to Glass-Glass Solar Panels:

Glass-glass PV modules, also known as double glass solar panels, are photovoltaic modules encapsulated with tempered glass on both the front and

Get a quote

JA SOLAR PV MODULES INSTALLATION MANUAL

The modules clamps must not contact the glass directly or deform and damage the glass in any cases, clamp need embedded with the rubber washer, which plays a buffer function when

Get a quote

What are Double Glass Solar Panels?

Double-glass solar modules are made up of two layers of tempered glass that cover both sides of the solar panel. As snow accumulates on a typical solar panel or people

Get a quote

6 FAQs about [Structure of double-glass modules]

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

Why are double glass modules symmetrical?

Mechanical constraints on cells: the fact that the structure of the double glass modules is symmetrical implies that the cells are located on a so-called neutral line, the upper part of the module being in compression during a downward mechanical load and the lower glass surface being in tension.

What is the thickness of a glass module?

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

What is a double glass (Dual Glass) solar panel?

A double glass (Dual Glass) solar panel is a glass-glass module structure where a glass layer is used on the back of the modules instead of the traditional polymer backsheet. Double glass solar panels were originally heavy and expensive, but the lighter polymer backing panels gained most of the market share.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Guess what you want to know

-

Use of double-glass photovoltaic modules in Saudi Arabia

Use of double-glass photovoltaic modules in Saudi Arabia

-

High-efficiency bifacial double-glass monocrystalline modules

High-efficiency bifacial double-glass monocrystalline modules

-

Weight of double-sided double-glass modules

Weight of double-sided double-glass modules

-

Monocrystalline silicon double-glass bifacial photovoltaic modules

Monocrystalline silicon double-glass bifacial photovoltaic modules

-

Black double-glass photovoltaic modules

Black double-glass photovoltaic modules

-

Thin-film double-glass photovoltaic modules

Thin-film double-glass photovoltaic modules

-

Main uses of double-glass modules

Main uses of double-glass modules

-

Chad double-glass photovoltaic modules

Chad double-glass photovoltaic modules

-

Slovakia double-glass photovoltaic modules

Slovakia double-glass photovoltaic modules

-

Huawei s high-efficiency double-glass modules

Huawei s high-efficiency double-glass modules

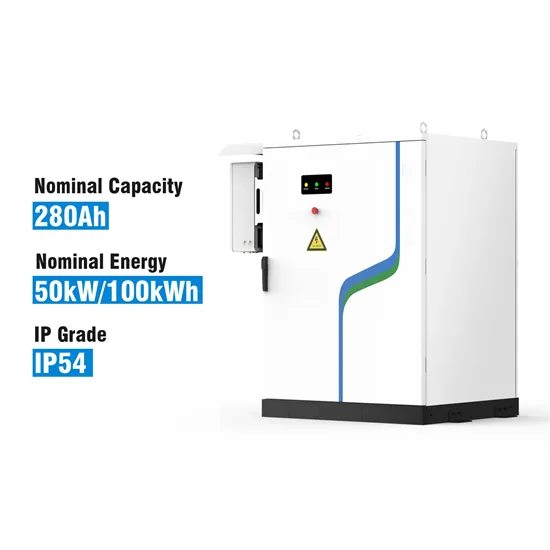

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.