Canadian Solar TOPCon Module Technical White Paper

Since 2019, CSI Solar has been developing N-type TOPCon (Tunnel Oxide Passivated Contacts) technologies, and now launches a diversified TOPCon module portfolio covering both 182mm

Get a quote

Meyer Burger to produce only double glass modules

The plant will not reach the mark of one gigawatt of manufactured module output until 2024. "It''s not just about expanding capacity," explained

Get a quote

US8372909B2

WO2024223730A1 2023-04-25 2024-10-31 Tenachem Edge seal for manufacturing two-pane or multi-pane insulating glass or solar modules comprising a photocured acrylic sealant

Get a quote

JA Solar: The Comprehensive Review

The double glass modules have a different backsheet than the traditional polymer ones. These units are covered with heat-strengthened glass that leads to lower power

Get a quote

GoodWe unveils double-glass TOPCon bifacial solar

China-based PV inverter manufacturer GoodWe has unveiled new bifacial modules based on n-type TOPcon technology. "Whether installing it on

Get a quote

2025 Guide to Dual-Glass Solar Modules: When Premium Panels

Complete guide to dual-glass solar panels: applications, benefits, costs & limitations. Learn when this premium technology provides genuine value vs conventional panels.

Get a quote

Double Glass PV Modules Future-proof Strategies: Trends,

Competition among major players like Trina Solar, JinkoSolar, and JA Solar is driving innovation and price competitiveness, making double-glass modules increasingly accessible to a broader

Get a quote

Bifacial Solar Panels: Innovative And More Efficient

Canadian Solar Canadian Solar has combined advanced bifacial cell technology with its double glass module manufacturing expertise to develop the

Get a quote

Custom Double Glass Solar Panels: What You Need

We combine double glass construction with back contact cells and can even customize the size, shape, and electrical configuration. Whether you

Get a quote

D MAX BIFACIAL DOUBLE GLASS MODULE

What is a double glass (Dual Glass) solar panel? A double glass (Dual Glass) solar panel is a glass-glass module structure where a glass layer is used on the back of the modules instead

Get a quote

DAS Solar''s N-type modules receive high ratings in PV Magazine

As a result of their outstanding performance in tests such as visual appearance, EL, power temperature coefficient, and PID, DAS Solar''s 72-cell bifacial double glass modules

Get a quote

Automatic 250MW Glass Glass Solar Photovoltaic

Since 2003, many Companies producing Double glass PV modules and BIPV have been using the ECOLAM series as their 1st choice laminator, granting it

Get a quote

Double Glass Module Photovoltaic Glass Market

The shift toward double glass modules in the photovoltaic industry is driven by their **superior durability, higher energy yield, and alignment with sustainability goals**. Unlike traditional

Get a quote

Custom Double Glass Solar Panels: What You Need to Know

We combine double glass construction with back contact cells and can even customize the size, shape, and electrical configuration. Whether you need a 100W small panel

Get a quote

Single-glass versus double-glass: a deep dive into module

Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market''s favour. However, this trend is not

Get a quote

Top 10 photovoltaic glass manufacturers in China in

It is usually divided into cover glass for conventional photovoltaic modules, cover and back glass for double glass modules, and TCO glass for thin film

Get a quote

PVB Double Glass Photovoltaic Module Analysis 2025-2033:

The global PVB double glass photovoltaic module market is projected to reach USD XX million by 2033, exhibiting a CAGR of XX% during the forecast period. Strong demand

Get a quote

Trina Solar: Double-Glass

As one of the first batch of companies that promote and commercialize double-glass modules, Trina Solar makes its double-glass modules, which has won industry-wide

Get a quote

JA Solar hypes its double-glass PV modules | Solar Builder

To meet the demand, JA Solar Holdings Co. announced that its standard 60-cell double-glass modules successfully passed all the reliability tests required by IEC61215 and

Get a quote

JA Solar hypes its double-glass PV modules | Solar

To meet the demand, JA Solar Holdings Co. announced that its standard 60-cell double-glass modules successfully passed all the reliability

Get a quote

What are the advantages of dual-glass Dualsun modules?

POE (Polyolefin Elastomer), the preferred solution for dual-glass modules. As these materials have different chemical compositions, the lamination parameters and expected properties,

Get a quote

DAS Solar''s N-type modules receive high ratings in

As a result of their outstanding performance in tests such as visual appearance, EL, power temperature coefficient, and PID, DAS Solar''s 72-cell

Get a quote

JA Solar Releases New Double-glass Modules

The Company launched the mass production of its double-glass modules for the global market in early August 2015. As the installation of solar electricity generation grows at an unprecedented

Get a quote

GoodWe unveils double-glass TOPCon bifacial solar modules

China-based PV inverter manufacturer GoodWe has unveiled new bifacial modules based on n-type TOPcon technology. "Whether installing it on a carport, flat-to-pitched roof

Get a quote

Bifacial Mono PERC Double Glass Module Strategic Insights:

The global Bifacial Mono PERC Double Glass Module market is experiencing robust growth, driven by increasing demand for renewable energy sources and the inherent

Get a quote

Double the strengths, double the benefits

At IBC SOLAR, we are committed to providing cutting-edge photovoltaic solutions tailored to diverse needs. Our partnership with leading manufacturers ensures a range of high

Get a quote

6 FAQs about [Which company is good at producing double-glass modules ]

What is the best double-glass module?

When it comes to double-glass, Trina Solar’s double-glass module is the most sought after product in the market. As one of the first batch of companies that promote and commercialize double-glass modules, Trina Solar makes its double-glass modules, which has won industry-wide recognition for its high quality.

Are double-glass modules hard to remake?

Double-glass modules are hard to remake, because they are no longer based on backing sheet,” he continued. Yin’s confidence comes from Trina Solar’s technical strength. During the past 20 years, Trina Solar has been constantly treading on the path of technological innovation, consistently paying high attention to investment in R&D.

Are bifacial double-glass modules a good choice?

There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market’s favour. However, this trend is not without its risks.

Why should you choose double-glass module?

Double-glass module is not subject to potential induced degradation (PID) and boasts of excellent durability, low permeability, long life cycle and other superior qualities. And its many advantages have enabled it to yield unbelievable results in China’s subsequent Top Runner Program.

Why do we have higher expectations on double-glass modules?

We have already realized the high shipment goal to lead the industry, now we have higher expectations on double-glass modules. At present, double-glass modules are subject to some non-technical problems, failing to make due and effective breakthrough. It is a pity.

How many double-glass modules were sold in China in 2018?

According to the statistics, double-glass modules with a total output reaching up to 12GW were sold in China in 2018. With setting up of agriculture-solar PV plants, hydro-solar PV plants, BIPV and other new PV plants, the market scale of double-glass modules will be further broadened ceaselessly.

Guess what you want to know

-

Which company is good for battery cabinets

Which company is good for battery cabinets

-

Which factory has double-glass modules in Israel

Which factory has double-glass modules in Israel

-

Turkish PVB double-glass photovoltaic modules

Turkish PVB double-glass photovoltaic modules

-

Double-glass multi-crystalline modules and multi-crystalline modules

Double-glass multi-crystalline modules and multi-crystalline modules

-

Which company is best for energy storage photovoltaic projects in Bahrain

Which company is best for energy storage photovoltaic projects in Bahrain

-

Which communication company has more 5G base stations

Which communication company has more 5G base stations

-

Which photovoltaic power generation and energy storage company is best in Egypt

Which photovoltaic power generation and energy storage company is best in Egypt

-

British PVB double-glass photovoltaic modules

British PVB double-glass photovoltaic modules

-

Structure of double-glass modules

Structure of double-glass modules

-

Which photovoltaic panel is good

Which photovoltaic panel is good

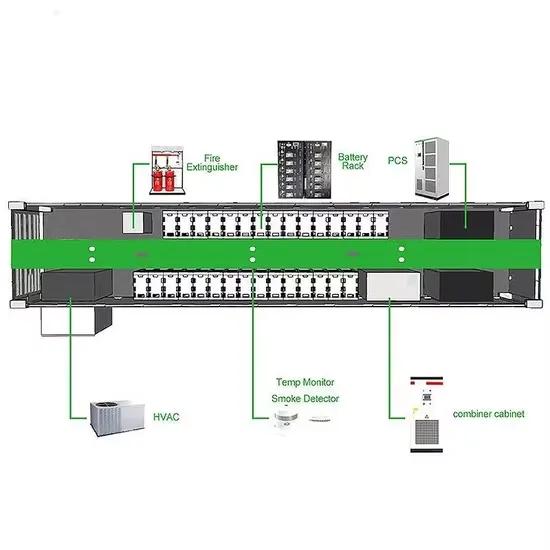

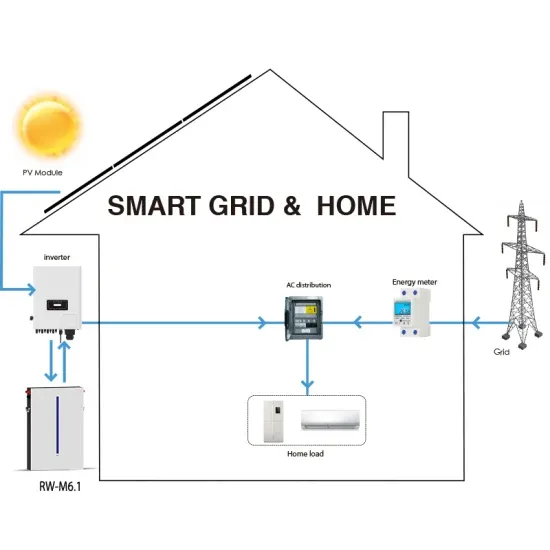

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.