Monocrystalline PERC Bifacial Dual Glass Solar PV

EVO 6 Series Mono PERC 120 Half Cells 590W 595W 600W 605W 610W Bifacial Dual Glass Solar Module Based on 210mm silicon wafer and 120 half-cut

Get a quote

Poly Crystalline Solar Modules – High Efficiency

Durasol Poly Crystalline Solar Modules are designed for high-efficiency solar power generation, offering cost-effective and durable performance for

Get a quote

Long-term reliability of silicon wafer-based traditional

In this work, we performed strict tests in climate chambers to simulate the outdoor field operations, to investigate the long-term reliability of double glass and

Get a quote

INSTRUCTIONS FOR PREPARATION OF PAPERS

A frameless double-glass module and a traditional PV module with a 3.2mm glass with an aluminum frame were both qualified to withstand heavy accumulations of snow and ice under

Get a quote

Advanced radiative cooler for multi-crystalline silicon solar module

The crystalline silicon solar module operates in an outdoor environment and exposed to radiation, ambient temperature and humidity. This paper focuses on the

Get a quote

[citation report] The lamination of (multi)crystalline and thin film

China is the world''s largest manufacturer of multi-crystalline silicon photovoltaic (mc-Si PV) modules, which is a key enabling technology in the global transition to renewable electric

Get a quote

Glass/glass photovoltaic module reliability and degradation: a review

Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Get a quote

(PDF) Long-term reliability of silicon wafer-based traditional

Traditional backsheet modules have higher WVTR and greater Pmax degradation, while double glass modules are impermeable and have much lower Pmax degradation.

Get a quote

Characterization of Multi Crystalline PV Modules under

A new report from NPD Solar Buzz states that the production of multi crystalline silicon (C-Si) solar photovoltaic (PV) modules is set to dominate the PV manufacturing industry by 2014,

Get a quote

A generic concept to overcome bandgap limitations for

Here we report a generic concept to alleviate this limitation. By integrating series- and parallel-interconnections into a triple-junction configuration, we find significantly relaxed

Get a quote

Advantages and disadvantages of double glass crystalline silicon modules

Are double-glass PV modules durable? Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this

Get a quote

Comprehensive investigation of rooftop photovoltaic power plants

Tahri et al. 11 investigated the performances of two different PV systems based on mc-Si (multi-crystalline) and CIS (copper indium selenium) modules.

Get a quote

Thin Film vs. Crystalline Silicon PV Modules

There is a competitive price advantage of Thin Film modules over Crystalline Silicon PV modules. Despite the fact that the global thin film module production capacity have increased

Get a quote

The degradation of multi-crystalline silicon solar cells after damp

The key factor for excellent performance of Si wafer-based double glass PV modules is replacing the polymer backsheet by a glass panel with impermeability to water

Get a quote

Modelling of a double-glass photovoltaic module using finite

The PV module cell temperature is a function of the physical variables of the PV cell material, the module and the surrounding environment. A simulation model of finite differences

Get a quote

Towards 50 Year Lifetime Photovoltaic Modules

The Double Glass versus Glass/Backseat project conducted at Case School of Engineering''s Solar Durability and Lifetime Extension (SDLE) Research Center is detailed below.

Get a quote

(PDF) Long-term reliability of silicon wafer-based

Traditional backsheet modules have higher WVTR and greater Pmax degradation, while double glass modules are impermeable and have

Get a quote

Modelling of a double-glass photovoltaic module using finite

A simulation model of finite differences describing a double-glass multi-crystalline photovoltaic module has been developed and validated using experimental data from such a

Get a quote

Environmental influence assessment of China''s multi-crystalline

The environmental burden of multi-Si PV modules in China has been discussed in existing studies, however, their data are mostly from local enterprises, and none of their environmental

Get a quote

Heat transfer modeling and temperature experiments of crystalline

In this study, the time-dependent thermal performance of crystalline silicon photovoltaic (PV) modules with glass-glass (GG) and glass-back sheet (GB) configurations

Get a quote

High performance double-glass bifacial PV modules through

Significant amount of near infrared light passes through bifacial cells. Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements.

Get a quote

Photovoltaic Cell Generations and Current Research Directions

Multi-junction based solar cells and new photovoltaic cells with an additional intermediate energy level are expected to provide extremely high efficiency. The research in this case focuses on a

Get a quote

Long-term reliability of silicon wafer-based traditional backsheet

In this work, we performed strict tests in climate chambers to simulate the outdoor field operations, to investigate the long-term reliability of double glass and traditional backsheet PV

Get a quote

(PDF) Long-term reliability of silicon wafer-based

The key factor for excellent performance of Si wafer-based double glass PV modules is replacing the polymer backsheet by a glass panel with

Get a quote

Photovoltaic Cell Generations and Current Research

Multi-junction based solar cells and new photovoltaic cells with an additional intermediate energy level are expected to provide extremely high efficiency.

Get a quote

6 FAQs about [Double-glass multi-crystalline modules and multi-crystalline modules]

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

Why are double-glass modules important?

Double-glass modules have increased resistance to cell micro-cracking, potential induced degradation, module warping, degradation from UV rays, and sand abrasion, as well as alkali, acids or salt mist.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Guess what you want to know

-

Notes on installation of double-glass modules

Notes on installation of double-glass modules

-

Transparent double-sided double-glass photovoltaic modules

Transparent double-sided double-glass photovoltaic modules

-

Thin-film double-glass photovoltaic modules

Thin-film double-glass photovoltaic modules

-

Monocrystalline p-type bifacial double-glass modules

Monocrystalline p-type bifacial double-glass modules

-

Chad double-glass photovoltaic modules

Chad double-glass photovoltaic modules

-

Kenya double-glass photovoltaic modules

Kenya double-glass photovoltaic modules

-

Syria double-glass photovoltaic modules

Syria double-glass photovoltaic modules

-

Advantages of double-glass photovoltaic modules

Advantages of double-glass photovoltaic modules

-

Solar double-glass photovoltaic modules

Solar double-glass photovoltaic modules

-

Structure of double-glass modules

Structure of double-glass modules

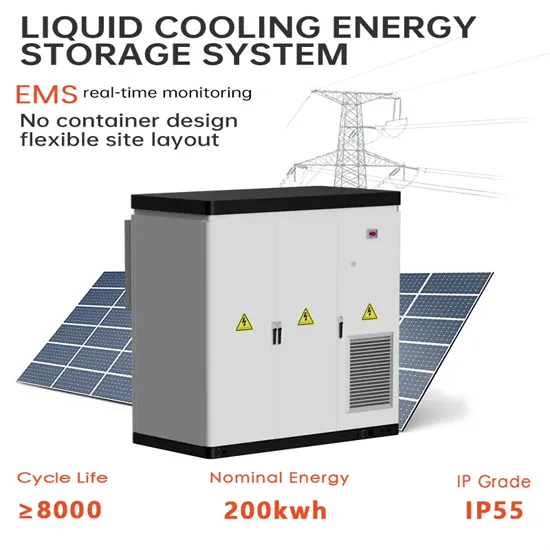

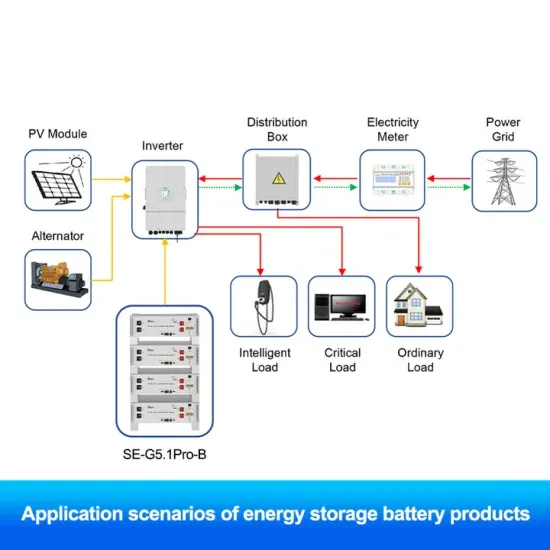

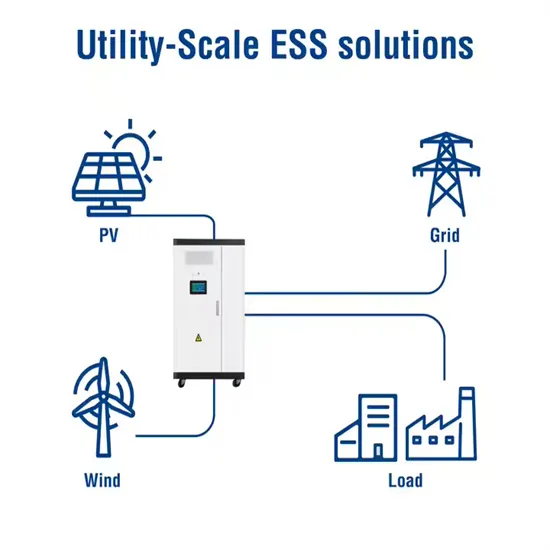

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.